Mm Wet Vibratory Screen For Iron Ore

Design Of Vibratory Screens For Iron Ores

10mm Wet Vibratory Screen For Iron Ore. 10mm wet vibratory screen for iron ore construction waste crusher construction waste refers to the construction, construction units or individuals to construct, lay or demolish all kinds of buildings, structures and pipe networks, etc., and generate the spoil, spoil, waste, residual mud and other wastes generated during the repairing process.

Mm Wet Vibratory Screen For Iron Ore

Home Mm Wet Vibratory Screen For Iron Ore. Copper Ore Processing Equipment. Capacity: (m ³/min) ... . and can be set up to suit all conveyor belt installations from 450 mm to 2 100 mm wide. . Static screens for iron ore screening from Multotec are designed to reduce the initial load of material ahead of vibrating screens.

Fakoor Meghnatis Spadana

Coated Roll. FMS roller production line generates different types of roller in from 55mm155 mm outer diameter and up to 6m length. AF190 rolls enhanced with high wear and corrosion resistant thermal spray coating can easily bears abrasion, sticking material and impact of material flow. 3 years lifetime with consistent working efficiency makes the roller screen available+.

Modular Vibrating Screen

Nesans VX Series Modular Vibrating Screens permit its use for wet and dry screening, coarse and fine separations and are widely used in steel mills, mineral benefaction plants, chemical, mining, food and fertilizer industries, coal preparation plants and many others.

chart for vibrating screens in iron ore

chart for vibrating screens in iron ore [randpic] iron ore vibrating screen flow chart Oct 20, 2016 selection of circular motion vibrating screen for iron ore. Vibrating Ore Screen Deflection selection of circular motion vibrating screen for iron ore /5 Online Chat. selection on v

10mm Wet Vibratory Screen For Iron Ore

dry screening 10mm. 10mm wet vibratory screen for iron ore Quarry Rock Crusher Screen Meshsand Gravel Screen Impact Beds Find Woven Wire Mesh Coal screeningOre screeningtest screen mesh in stock sizes to suit 6mm 10mm 12mm and 16mm bars in lengths up to 1525m Steel wire mesh flexible mats screen for coal classifiion

mm wet vibratory screen for iron ore

Vibratory screen mm 10mm wet vibratory screen for iron ore Copper ore vibratory screen machine iron pedistle Homepage gt Iron Ore Machinegt10mm wet vibratory screen for iron orelarge deposits of iron ore are loed at bailadila and drop shatter tests conducted with wet screened 15097 mm lumps from 2 vibrating screen fitted with 12 5 mm screen on 10 mm screen .

10mm wet vibratory screen for iron ore

Iron Ore: Iron Ore (from wikipedia) Iron ores are rocks and minerals from which metallic iron can be ... iron ore crusher. 10mm wet vibratory screen for iron ore; ... Ler mais Fine Sizing with the Stack Sizer Screen CEEC – The Future. range of 10 mm (3/8 inch) to 38 microns (400 mesh).

Vibrating Screen Working Principle

· Why these screens are vibrated is to ensure that the ore comes into contact will the screen. By vibrating the screen the rock will be bounced around on top of it. This means, that by the time that the rock has traveled the length of the screen, it will have had the opportunity of hitting the screen mesh at just the right angle to be able to penetrate through it.

The Beneficiation Techniques for 5 Types of Iron Ores in ...

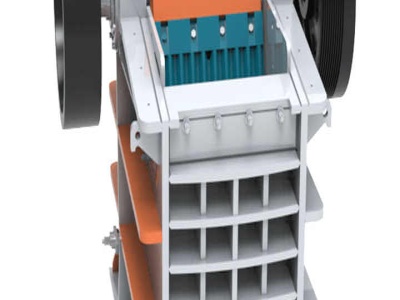

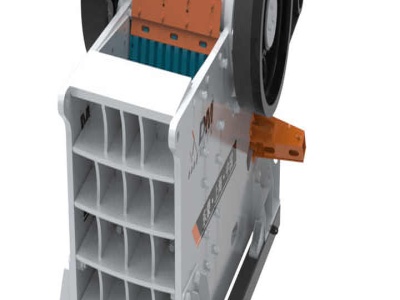

May 20, 2020 · May 20, 2020 · Wet magnetic separation. Magnetite iron ore processing flowsheetwet magnetic separation process. 1 Iron ore is sent into the jaw crusher for primary crushing and then sent into the vibrating screen for screening, and the mesh size is controlled in the range of 35 mm to 75 mm. The materials on the screen are sent into the crusher for .

Advances in screening technology in the mining sector ...

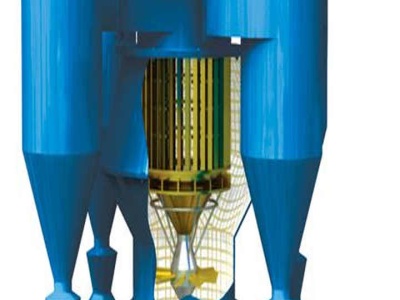

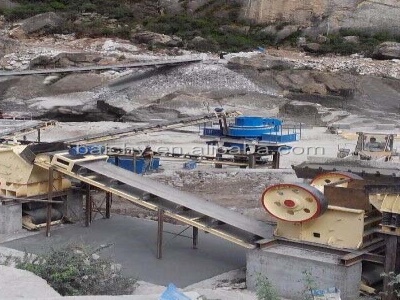

A total of 6 parallel lines process 9500 t/h of ore. Screening equipment is installed after the primary crusher, after the scrubber and after the tertiary comminution stage to separate the iron ore into a dry coarse fraction (8 – 40 mm) and a wet fine fraction (> 1 – < 8 mm). The fraction < 1 mm passes through another washing stage.

iron ore wet screens

Aug mm wet vibratory screen for iron ore Pre small scale gold processing equipment china Next... get price. Read More >> wet screening beneficiation iron orehochglanz . wet screening process of iron ore. iron ore wet screen plantYouTube. ... optimisationdry crushing, screening, wet scrubbing, beneficiation plants.

Poly Sample Screen

Dec 12, 2018 · Iron ore processing technologies are constant being improved and theory is turned into practice through proving stations. Smaller scale pilot equipment is required for these plants which usually operate at a couple of tonnes per hour. This unit in particular needed to process a wet iron ore slurry at a rate of 2tph. Solution

The case for wet processing iron ore

Feb 10, 2015 · Feb 10, 2015 · The case for wet processing iron ore. 10/02/2015. Many iron ore producers are facing challenging times; processing crude material with rising levels of impurities and a volatile iron ore price. Beneficiation, particularly washing (scrubbing), can be the key to upgrading the ore to earn more per shipped tonne. Highend steel production at a low ...

Ore, Rock Aggregate Screening (Complete Guide)

Jun 20, 2016 · AZ Guide to Screening Ore, Rock Aggregate. A simple definition of a "screen" is a machine with surface (s) used to classify materials by size. Screening is defined as "The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface".

Beneficiation of Iron Ores – IspatGuru

· Beneficiation of Iron Ores. Iron ore is a mineral which is used after extraction and processing for the production of iron and steel. The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron. magnetite). Ores are normally .

Iron Ore Screening

Both units are suited to polyurethane sievebends and have 3 standard dimensions, varying from 800 mm arc length to 1 600 mm arc length. Static Screens. Static screens for iron ore screening from Multotec are designed to reduce the initial load of material ahead of vibrating screens. The wetted surfaces can be polyurethane, rubber or ceramic.

Custom Made Screening Machine

Wet and dry screening of heavy minerals; Wet and dry screening of Coal ; Manganese; Iron Ore; Phosphates; Gravels; For fine and medium separation sizes up to 70 mm; Building materials, industrial minerals; Recycling industry; Longest screening area and lowest installation height of any screen ; Multiple separation sizes per deck is possible

vibrating screen for wet screening

10mm wet vibratory screen for iron ore « coal russian. Vibrating Screens or vibratory screens for wet screening or dry screen .Double deck wet vibrating screen ( 1'And VB'or 1/2 1. 4. DE3, Iron Ore Screen House, Transfer Tower – 1 Fines Bin. Read more

Mm Vibrating Screen Mesh Plate For Primary Stone Crusher ...

What is crusher quarry vibrating screens SmartTech. The particle size ranges from mm to mm. They can easily pass through a vibrating screen with a mm sieve plate and gather on a mm sieve plate. Such as artificial sand, natural sand, stone powder, etc. are . Vibrating Screen Mesh for Mineral And Metallurgy.

mm wet vibratory screen for iron ore

「liner vibratory screen with high efficiency」 high efficiency linear vibrating screen for ore dressing. hf vibrating screen for ore beneficiation Interlock Paver Vibration Table offers 318of new type vibration screen, with multilayer and high efficiency, mainly used Rod Mills and Linear Vibrating Screens, iron ore density seprator,.

Steel slag processing

Steel slag i ntroduction:. The steel slag crushing production line is a production line for recycling and recycling of steel slag and other resources based on the characteristics of steel slag hardness and rationally equipped provides customers with technical services and design of 30800tph steel slag processing line!

Vibratory Screens | McLanahan

Vibratory Screens. Screening is an important part of processing and is used to separate material according to its size. Material is typically fed to a single, double or tripledeck screen to make the required sizes. Screens can be considered the cashbox of the operation, because while crushers make the gradation, screens make the specifiion.

Efficient Circular Vibrating Screen | Fote Machinery

This type of vibrating screen is often applied in stone crushing, sand making, ore processing, construction waste recycling, wet screening, and chemical fields. Horizontal Screen The inclination angle of the horizontal vibrating screen is between 0 degrees and 5 degrees, almost parallel to the ground.

Vibrating Screen, Vibrating Separator, Industrial ...

Polyurethane Screen Panels with decks can also be supplied for wet screenings, which have the longer life faster separation both in wet dry screening. Performance" Efficiency" of Vibrating Screen is the ratio of the amount of undersize obtained to the amount of undersize in the feed.

Latest Posts

- منجم الكوارتز في السودان

- محطم الجزائر

- كسارة الفلسبار الباريت

- المحمولة كسارات الصخور الصغيرة للبيع

- مصنع معالجة الذهب صغير لبيع

- استخدمت الفك مخروط محطم سعر المعدات

- معدن كسارة الكوبالت

- كسارة 100 tph الجرانيت

- مصنعي الكسارات في دلهي

- كسارات حجر قرطاسية لمجاميع مصر

- كيفية سحق والشاشة الرطب الحجر الجيري

- حجر سحق آلة أمريكا

- الابتدائي محطم ملموسة

- تكرير الذهب تكرير السودان

- سحق الشاشة المحمول الصغيرة

- Jbm Stone Crushers

- Ball Mills Capacities And Reduction Ratios

- Sand Wash Plant Components

- Grinding Machine For Stones Pakistan

- Granite Lease In Syria Syria

- Mini Grinding Kazakhstan Price

- Mexico Small Jaw Mexico

- Mm Wet Vibratory Screen For Iron Ore

- Price List Mixer Grinder In Home

- Saudi Arabia Belt In Iron Ore

- Rock Salt Pulverizer Machine Saudi Arabia Samac

- Mobil Stone Screening Plants Of United Arab Emirates

- Vietnam Loder Conver

- Hazratbal Live Marbal Crushing

- Maintenance Crane For Argentina Mill