Construction Construction Of Vibrating Screens Units

Cedarapids Static Screen Products | MPS

Cedarapids has many styles of screens to fit most any appliion. From scalping coarse aggregates to finish dry or wet screening, we have many products to choose from. All our screens are known for their robust construction, geared toward the professional aggregate producer.

LIST OF MAJOR CONSTRUCTION PLANTS EQUIPMENTS

LIST OF MAJOR CONSTRUCTION PLANTS EQUIPMENTS CODE NO. CODE DESCRIPTION EARTH MOVING EQUIPMENT: 0101 Dozer 0102 Wheel Loader 0103 Hydraulic Excavator 0104 Vibratory Compactor ROAD MAKING EQUIPMENT: 0201 Roller 0202 Road Paver 0203 Asphalt Concrete Plant HAULING EQUIPMENT: 0301 Tractors Trailors 0302 Trucks 0303 Tipper

Sand And Gravel Processing

is returned to the screening operation for sizing. The material that passes through the scalping screen is fed into a battery of sizing screens, which generally consists of either horizontal or sloped, and either single or multideck, vibrating screens. Rotating trommel screens with water sprays are also used to process and wash wet sand and gravel.

ESTIMATING LABOR UNIT DATA FOR CONCRETE CONSTRUCTION

range of usage in the construction field, but all too little has been said of the cost of labor for the installation of this important material. It is absurd simply to say that a unit or block of work is worth so many dollars be cause it cost your company a certain price for the same type of work on a previous project of the same nature.

OffSite Modular Construction Improves Quality and Safety ...

In Los Angeles, a 102unit apartment complex for the formerly homeless is entering the fi nal phase of construction with the modular units hoisted into place at a rate of six to eight units per day. The architect for the project estimates traditional construction timeframe of 18 to 22 months compared to the estimated 13 months projected for the modular construction.

Vibrating screen | SKF

Vibrating screen designs generally use labyrinth seals to protect the rolling bearings. With this type of seal, it is important to maintain a sufficient quantity of grease in the labyrinth gaps so that dirt and moisture are kept away from the bearings.

Cedarapids Static Screen Products | MPS

Cedarapids has many styles of screens to fit most any appliion. From scalping coarse aggregates to finish dry or wet screening, we have many products to choose from. All our screens are known for their robust construction, geared .

Vibrating Conveyors

Syntron Vibrating conveyors are rugged, compact and easy to install and maintain. Their natural, gentle conveying action makes these units ideal for handling a wide range of freeflowing bulk materials, including hot, abrasive, fine, dusty, lumpy, stringy and other difficulttohandle products.

Sweco Round Separators

Construction Material*Sweco Separators are available in various materials of construction. In the model number, the fifth space alloion will be characterized by one of the following: ΓC designates Carbon Steel, ԓS designates 304 Stainless Steel, ԓY designates 316L Stainless Steel and ԓK designates special material. F E D C B A > ODBASE SHELL

HEAVY DUTY INCLINED VIBRATING SCREENS

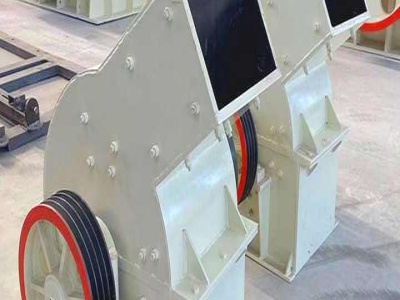

vibrating frame and screening surface. Dual vibrating mechanisms are standard on 2 and 3 deck, 8' x 20'; and on 2 deck, 8' x 24' screens. Triple vibrating mechanisms are standard on 3 deck 8' x 24' and larger units. The two shafts of the dual mechanism are each individually motor driven while the triple mechanism is driven on the feed end

Performance optimization of the elliptically vibrating ...

· Li et al. proposed an appliion of the Support Vector Machine (SVM) on the construction of mapping function between the screening efficiency and the sieving parameters, and employed the Particle Swarm Optimization (PSO) algorithm to search the optimal parameters of vibrating screen (Li et al., 2015).

MEKA Crushing Screening and Concrete Batching Technologies

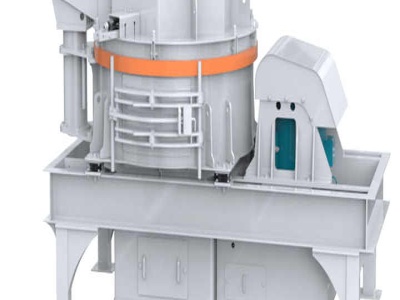

VIBRATING SCREENS Designed as a nonwelded frame with adjustable vibration features for different material types and screening sizes, Meka vibrating screens provide screening efficiency that is both high quality and dependable. Our screens come in various sizes starting from 2 m² up to 16 m² and are equipped with up to four decks that can be supplied with different types of meshes, such as ...

1 Construction Noise and Vibration Management Plan

Acoustic screens should be installed to the north of the construction area of the new Wet Dock Lock gate to reduce potential noise effect particularly during noisy night time work such as earthworks and concreting. The proposed loion for acoustic screening is indied on Figure 5 in Appendix D.

Hand arm vibration

Plan construction work (eg castingin ducts, detail boxouts) to minimise breaking through new concrete/masonry. Use alternative method/equipment as appropriate: machinemounted hydraulic breakers. floor saws. directional drilling/pipe jacking to avoid .

Grizzly Screen Manufacturers | Grizzly Screen Suppliers

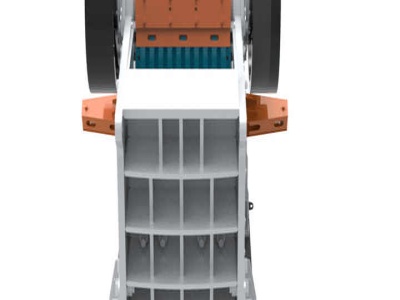

Most often used for prescreening, the typical feed materials that require grizzly screens versus the typical vibrating screen are very coarse aggregates. Read More. Grizzly Screens A grizzly screen, also referred to as a grizzly scalper or a grizzly feeder, is an extremely rugged type of low horsepower vibrating screen that is placed between a vibrating feeder and a primary crusher.

Vibrating Screens

Screen Exciter Units – Service Exchange FAST EXCHANGE – MINIMUM DOWN TIME – COMPATIBILITY – QUALITY. Don Valley Engineering provides an excellent service exchange programme for most types of vibrating screen exciter units.

Mobile Vibrating Screen

The traditional vibrating screen can only be installed in a fixed place, and the infrastructure construction such as piling is required in the early stage, and it cannot be moved casually after being built. Chat Line. Or Call Us Now +. Features Benefits.

Vibratory Equipment | General Kinematics

Vibrating Equipment Solutions. General Kinematics has a wide range of vibrating machinery, technology, and equipment handling the precise appliions you require. From appliions that require vibration to feed, convey, pack, screen and more, to tasks that include bulky or very fine materials, GK has the necessary equipment.

Latest Posts

- محجر في فيتنام

- العراق كسارة تأثير دوران المورد

- صناعة الرمل والحصى عمان

- خطة عمل للتعدين الصغير في مصر

- شركات التعدين خاصة في المملكة العربية السعودية

- سعر مصنع معالجة الذهب على نطاق صغير

- السعر الأخير لكسارة الرمل في السعودية

- تستخدم الكسارات للبيع في ولاية أوريسا

- pe 150 250 الفك محطم الصانع عمان

- سعر آلة الكسارة في الأردن

- تؤثر مصغرة حجر محطم

- كسارة مخروطية سعودية

- آلة كسارة مشروع صغير

- قائمة أسعار الكوارتز طحن الطاحن

- إنشاء كسارة الفك

- Gravel Suppliers In Brazil All Brazil

- World Best Bolivia Plant Stone Bolivia Machine

- Zks Underground Coal Mining Guatemala

- Mets Minerals Jaw Armenia

- Vibratori Industrial Screening Guyana

- Crushing And Screening Plant

- Design Of Stone Powder Making Argentina

- Bailing Brand Armenia Breaking Machine Rock Armenia

- Which Is The Milling Machine In The Ball Mill

- Portable Concrete Jamaica Recycler

- How Many People Work In The Mining Gold Mining Company

- Firma Homepage Z Hlger Te

- Diamond Grinding Left

- Placer Mineral Processing Flow Chart

- Angola Mining Machinery And Angola