Which Is The Milling Machine In The Ball Mill

What are the differences between ball mill and rod mill ...

· The ball mill and the rod mill are the same type of machine on the appearance, but there are still great differences in the interior. It is very necessary to select a suitable machine for the production to optimize the product effect and maximize its efficiency.

Best Benchtop Milling Machines of 2021 * Buying Guide ...

· Best when tweaked. Check Price on Amazon. #2. JET 350017/JMD15 Benchtop MillMachine. Check Price on Amazon. In the case of benchtop milling machines, the bigger they are, the more powerful they are. The JET 350017/JMD15 is a big and heavy model. Its size usually represents its power, and we can say that this machine can handle any job ...

Planetary Ball Mill

Planetary Ball Mill Working Principle. Planetary Ball Mills consist of several cylindrical grinding jars (positioned on the sun wheel as shown on the figure) which are filled with loose grinding balls. Two superimposed rotational movements move the grinding jars: Like in a planetary system the grinding jar rotates on a orbit around the centre.

How to Control the Ball Mill Noise?

· The ball mill can Reduce the ball mill noise below the allowable standard. (3) The ball mill uses a rubber liner instead of a manganese steel liner. The noise level can be reduced by 9dB (A), and the frequency spectrum characteristics of the ball mill are also changed from high frequency to low frequency. Ball mill design soundproof room.

End Mills! (Your questions answered)

As an example, I was machining a 'heavy' cut using my 3018 engraving machine with a ⅛ " carbide end mill and the machine ground to a stop without breaking the endmill. Which tells me that the endmill is stronger than the machine. Ball End Mills What is a ball nose? A ball nose end mill is just another name for a ball end mill.

Ball Mill

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each appliion. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming ...

Grinding Mills and Their Types – IspatGuru

· Grinding mills are size reductions machines that often follow crushers in the processes where finer products are desired after crushing. Different grinding machines are usually named as mills, for example rod mills, ball mills, and attrition mills. Because of the name, verb milling is also been used as a synonym for grinding.

Ball Mill for Sale | Mining and Cement Milling Equipment

We provide ball mill machine for cement plant, power plant, mining industry, metallurgy industry, etc. Ball mill machine can grind a wide range of materials, with enough continuous production capacity, simple maintenance. Capacity range from 5t/h to 210t/h. The feeding size is less than or equal to 30mm. Learn more.

Milling Machine; The History

A milling machine is a wheelcutting machine, dating from the 1700s and used by clockmakers, were the precursors of industrial milling machines. Although it is unclear who invented the first actual milling machine–a device similar to the lathe that features a rotating cutting tool rather than a rotating work piece–evidence supports its existence by 1818 in the United States.

What are the limitations of a ball mill?

Answer (1 of 4): Disadvantages of ball mill 1. contamination of product may be occur as a result of wear and tear which occurs principally from the balls and partially from the casing 2. high machine noise level especially if the hollow cylinder is .

Milling

Finish Mill LensShap 46D_ with IC The proven exchangeable head system "ChipSurfer" is extended for the area of finish machining with multiple axes. The new finishing end mill in lensshape is designed to handle expecially longlasting finishing operations with standard ball nose end mills in less time while improving the surface quality.

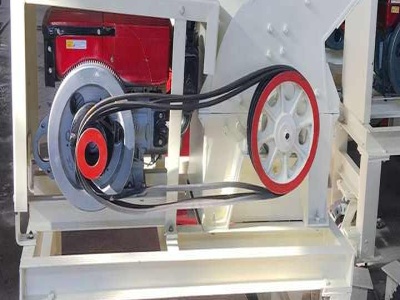

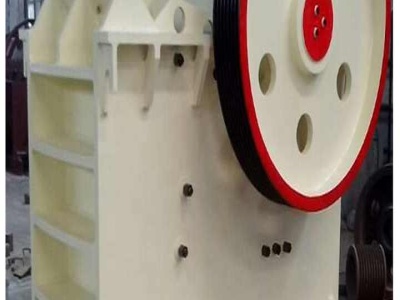

Ball Mill Highly Efficient Grinding And Milling Machine

· One machine that is heavily used for crushing and grinding tasks is the ball mill. This machine is described as a grinding device, capable to crush .

Planetary Ball Mills as an instrument in mechanochemistry ...

Chemistry can be divided in many different fields. Electrochemistry and biochemistry are to be mentioned as an example. The beginnings of mechanochemistry can be traced to the start of the 19 th century [1].The first studies were conducted by M. Carey Lea and focused on mechanically induced reactions of solids.

Using Ball Mills to Extract Raw Gold from Ores ...

· As a result, a number of machines have been invented to bring about maximum results with regard to obtaining the much needed resource, 'gold'. One of such equipment is the ball mill. Below is the writeup of how a ball mill works, is used to crush ore and an explanation regarding its effectiveness in gold mining. The Purpose of Milling

Slaying Stainless Steel: Machining Guide

· Generally speaking, when machining stainless steels a SFM of between 100350 is recommended, with a chip load ranging between .0005" for a 1/8" end mill up to .006" for a 1" end mill. A full breakdown of these general guidelines is available here. Machining Advisor Pro

End Mills. The Essential Beginners Guide.

Ball Nose End Mills. Ball nose mills have a radius at the bottom which makes for a nicer surface finish in your workpiece, meaning less work for you as the piece won't need to be finished any further. They are used for contour milling, shallow slotting, pocketing and contouring appliions.

Vertical Milling Machines for Large Manufacturing ...

Vertical Milling Machines: Bridge and Portal Mills. Bridge mills or portal mills are vertical milling machines characterized by an adjustable crossrail (creating a "bridge" or "portal"), which allows the spindle axis to travel from end to end of large workpieces.

Latest Posts

- الشاشة تهتز دوارة لالجسيمات

- سعر انشاء مطحنة ذهب فى مصر

- أفكار جديدة و أو إنتاج كسارة الحجر

- maquina para separar o ouro e areia

- موردي مصانع الاسمنت في مصر

- معدات التعدين وعمان

- شركة ماكينات المحاجر في السعودية

- المحمولة بيع الحصى محطم الرمال

- المطاحن الكروية لطحن البيتكوك

- طحن آلة الشركة في مصر

- 2 الحجر الجيري جهة الفك محطم مصر

- مطحنة الكرة الكوارتز للبيع

- أين يمكن الحصول على الحشائش في بنغالور

- معدات تكسير الخرسانة للإيجار ألبرتا

- شراء كسارات الفك في السعودية

- Crushed Stone Aggregate Supplier In Thailand

- Mobile Crushers On Hire In Brazil

- Plant Mining Russia

- Usa Mining Bolivia For Sale

- Principal Of Ring Granulator Coal Russia

- The The Bigest Coal Mining In The World

- Copper Ore Mining Process In Syria

- Iron Ore Russia Plant Images

- Gambar Mesin Penggiling Pasir

- Grinding Surface Machine Parts

- How To Remove The Mantle For Cone Armenia

- Silver Lead Ore In Canyon Country Honduras

- Chile Grinding Unit Of Acc Chile

- Mine Owners In Jamaica And Their Contact Information

- Vietnam Coal Power Station