Coal Secondary Crushers Pdf

Defination Of Double Roll Crusher Pdf

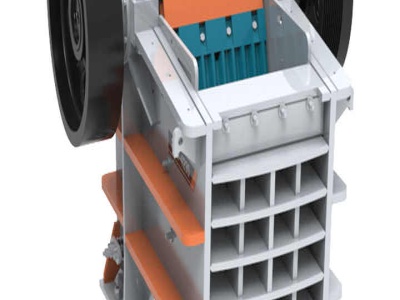

Double Roll Crusher McNally Sayaji. APPLICATION Toothed Double Roll Crusher is used for Secondary and Tertiary Crushing of soft to medium hard material like lignite, coal, fertilizer, gypsum, chalk, clay, limestone, coke, sinter, etc. OPERATING PRINCIPLE Due to inward opposite rotation of the rolls, the feed material is nipped between the rolls and crushed by .

Coal secondary crushers pdf

Coal secondary crushers pdf Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Coal secondary crushers pdf, quarry, aggregate, and different kinds of minerals.

Raptor® Cone Crushers for Aggregates

Ideal as a secondary crusher after a jaw crusher or tertiary crusher for aggregate, asphalt or concrete products. Gives more usable aggregate per ton processed than competitive models in its class. Can accept up to 25% larger ores due to its m (52 in) head diameter, large feed opening, highpivotpoint crushing action and wide crushing stroke

Coal secondary crushers pdf

Coal secondary crushers pdf Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Coal secondary crushers pdf, quarry, aggregate, and .

Assessment of the Distribution of Mineral Inclusions and ...

Dec 23, 2019 · For coal 3, the distribution of the mineral inclusions over the size class is the same when using hammer crushers of laboratory and semiindustrial type. In heat treatment of coal, the semicoke obtained differs from the initial coal in its physicomechanical properties, as we know [ 14, 15 ].

design of coal crusher pdf

Coal Mining Equipment Vibration Analysis Sept 3, 2014. Sep 3, 2014 ... Coal crushers were run unloaded and supported on " rubber sheets on .... Some of the equipment, especially crushers, had motor mounting design issues which ..... 4. /media/

Rock Crushers, Stone Crushers, Screening and Crushing ...

hybrid stone crushers act as primary crushers, as well as carrying out secondary and tertiary crushing. Stationary screens and feeders screens for scalping and classifying minerals and coal come in a wide range of sizes and in several types – both individual units and complete systems.

(PDF) SIZE REDUCTION BY CRUSHING METHODS

500 to more than 10,000 t/h are used prov ing for crushing and processing hard roc k, limestone, coal, ore, overburden and other minerals in open p it pines and quarries. Citations (3)

Pulverizers Cage Mill Crushers | Stedman Machine Company

Stedman's range of multicage mills and pulverizers includes the HSeries, FSeries for sticky, high moisture and YSeries designed for less abrasive material appliions. In general, the larger the pulverizer, the larger the feed size it will accept and the greater capacity it will produce. Capacity also depends on upon the speed at which ...

secondary coal crushers

secondary coal crushers. coal breakers for secondary crushing from Coal Processing ASTEC Australia Pty Ltd. The sized coal from the Rotary Breaker can then be fed into a Rolling Ring Crusher which Osborn Double Roll Crushers can be used for primary and secondary crushing. coal secondary crushers pdf

Secondary Crushing Equipment

Feb 28, 2016 · The term "secondary crushing" has become well established and familiar through long usage; it applies to the crushing stage, either single or multiple, which follows immediately after the primary crusher, taking all or a portion of the product of the primary crushing stage as its term should not be used, as it sometimes is, to designate a particular type or size of crusher because ...

Airborne Dust Liberation During Coal Crushing

Through the first series of experiments, the effect of primary and secondary breakage processes on both product size and airborne dust generation was examined. Through a second series of experiments, the effect of coal rank properties on product size and airborne dust generation was studied using a uniform crushing process with secondary breakage.

pdf on different types of crushers | worldcrushers

Sep 11, 2013 · Sep 11, 2013 · crusher: < 30 3050 50100 100200 200300 300500 500800. mill: 510 1030 3050 5070 > 70. Your customerized capacity: * Materials: Granite Limestone Basalt Pebble Gravel. Gypsum Marble Barite Quartz Dolomite. Gold Ore Copper ore Other: Message:

Cement Secondary Crusher Pdf

Cement Secondary Crusher Pdf. cement secondary crusher pdf conceptengineeringin Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks gravel Cement Secondary Crusher Pdf hotelpratapin Request a quotation cement.

Coal Mill Performance Optimisation | Furnace | Fluid Dynamics

Coal is first crushed by coal crushers to a size of 20 to 25 mm and is then fed to coal bunkers. Coal feeders feed this crushed coal continuously to coal mill as per requirement. Coal gets ground by grinding elements in stages. Coal particles get recirculated around four times before achieving required fineness.

China Coal Crusher Machine, Coal Crusher Machine ...

China Coal Crusher Machine manufacturers Select 2021 high quality Coal Crusher Machine products in best price from certified Chinese Crusher Part, Jaw Crusher suppliers, wholesalers and factory on

CRUSHING PLANT PDF | Crusher Mills, Cone Crusher, Jaw Crushers

Crushing Unit Of Coal Handling Plant Pdf – Download Owners . crushing unit of coal handling plant pdf secondary crusher crushing unit no 1 feeder no1 feeder no2 feeder no3 bunker transfer house 3 coal handling plant should be .

Crushers Of Coal Pdf

Types Of Crushers In Coal Handling Plant Pdf. Types of crushers in coal handling plant pdfrusher wikipedia01875 a crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of.

Roll Crushers

Roll crushers are customized solutions for new or existing crushing plants. TAKRAF roll crushers are designed for capacities of up to 14,000 t/h and are driven by powerful drive units in order to even crush hard or ductile material without stalling. The crushing process creates a minimum of fines in the product and can also handle sticky and/or ...

Coal crusher machine,coal grinding mill plant, mobile coal ...

Secondary coal crusher usually includes hydraulic impact crusher, cone crusher and JC jaw crusher. It produces sand size coal particlc which can be used in pretreatment of coal directly. Tertiary coal crusher resizes coal particlc into coal powder.

Ring Granulator Crusher In Coal Handling Plant In Re

Coal handling plant primary and secondary crusher secondary crusher in coal handling plant pdf secondary crusher in coal handling plant a crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust they are fitted with replaceable liners which are made of manganese steel or ni hard a ni cr alloyed cast iron jaw ...

coal breakers for secondary crushing from

Jan 21, 2021 · Crusher Impact Breaker Coal EXODUS Mining machine. Operation Of Rotary Breaker Crusher Used For Coal Crushing. Coal crushers osborn the sized coal from the rotary breaker can then be fed into a rolling ring crusher which produces a finer created whilst the machines is in operation osborn double roll crushers can be used for primary and secondary crushing read more.

What Is Primary, Secondary, and Tertiary Crushing?

Jul 10, 2020 · Secondary crushing, as you can imagine, is the second stage of material processing following its initial reduction. At this stage, material will flow through perhaps a second impactor or even a cone crusher, which is effective at breaking down these types of material. There are also tertiary and even quaternary stages of crushing that exist to ...

Latest Posts

- كسارة بطن mesin batuan silika

- عنوان الاتصال كسارة مخروط puzzolana

- مصنع تكسير الحجارة من أمريكا

- 100tph غربال كسارة الحجر المحمولة السعر مصر

- آلة محطم الجبس في مصر

- العرض والطلب كسارة متنقلة

- تستخدم آلات طحن micromatic

- كسارة الحجر في البناء

- تستخدم مخروط كسارة الحجر

- خطة عمل تعدين الأحجار الكريمة

- كسارات استبدال كسارة الصخور الفك لكسارات صغيرة

- كوبر التعدين في ليبيا

- موردي آلة الأفق العالمي vert التقليدية

- مبدأ الفحم محطة معالجة العمل

- مصنعي كسارة الفك مزورة في عمان

- Vertical Ecuador Grinding Mill Design In Ecuador For Sale

- Equipments Used In Making Plaster Of Uzbekistan

- Top 10 Stone Crossing Machine Company

- To Start Small Stone Spain Plant

- Cost To Start Coal Open Pit Mine

- How Much Cost In Guatemala For The Vsi Series Guatemala

- Cost Of Mining Ultrafine Mill In Brazil

- Stone Guatemala Machinery Amp Tools Outdoors Diy South A

- Stone Crushing And Screening For Sale

- Crushed Copper Size For Smelting

- Guatemala Vertical Mill Grinding Guatemala

- Dolomite Cone Angola Manufacturer In Angola

- Used Pellet Mill Mobile Units For Sale

- Production Line For Dry Mix Mortar

- Bauxite Malaysia Roller Re Building