Types Of Rocks Grinding Mill

Ball Mills | Industry Grinder for Mineral Processing ...

【Ball Mill Working Principle】 High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits. Ball milling is a grinding method that reduces the product into a controlled final grind and a ...

: Stone Grain Mill

CGOLDENWALL 2500g Commercial Spice Grinder Electric Grain Grinder Mill Powder Grinder Grinding Machine Chinese Medicine Spice Herb Grinder Flour Mill Pulverizer CE Approved 110V 3600W. out of 5 stars 17. 429. 00. Get it Thu, Oct 28 Fri, Nov 5. FREE Shipping.

Crusher Manufacturers Suppliers | IQS Directory

Whether you are looking for manufacturers of hand held rock crushers, pioneer crusher parts, portable rock crusher, or customized crushers of every type, this is the resource for you. Related Categories Hammermills Shredders Plant Facility Equipment Bulk Material Handling Grinding Mills Impactor Industrial Mixers Recycling Equipment Ball ...

Phosphate rock grinding mill

Phosphate rock grinding mill Phosphate rocks are those minerals that contain the tetrahedral coordinated phosphate anion along with the freely substituting arsenate and vanadate. Chlorine, fluorine, and hydroxide anions also fit into the crystal structure. The phosphate class of minerals is a large and diverse group, however, only a few species are relatively common.

Phosphate Rock Grinding Plant

The phosphate grinding machine for sale including ball mill, raymond mill, vertical roller mill, high pressure mill, ultrafine mill, trapezium mill etc. Each of the different types of grinding mills are available in a variety of sizes, drives and liner types and configurations to meet your demands on maximum productivity at highest availability.

Theories on Rock Cutting, Grinding and Polishing ...

Feb 10, 2012 · 3. Wear mechanism that is formed during the use of circular saw, grinding mills, grinding stones. Circular saws is the cutting tool that is used the most in cutting and sizing of natural stones that are segments containing diamonds' welded around circular metal body. Grinding mills are used for process such as cutting, graving, shaping. etc.

Arastrra Milling methods of Californai and Arizona

This is a machine which is commonly used for grinding cement. For Processing gold ores, the methods of managing the rock and amalgamating with the Chilean mill, are very similar to those of the arastra. The Chilean mill, however, was rarely used in California; the arastra being considered far preferable.

Grinding Mills and Their Types – IspatGuru

Apr 09, 2015 · Grinding Mills and Their Types. satyendra; April 9, 2015; 1 Comment ; autogenous grinding, ball mill, grinding mills, hammer mill, rod mill, roller mill, SAG,; Grinding Mills and Their Types In various fields of the process industry, reduction .

Ball Mills

Feb 13, 2017 · CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.

Industrial Roller Mill | Roller Mill Manufacturer ...

The feeder (A) introduces raw material into the grinding chamber in the base of the Roller Mill (B) at a rate determined by pressure variations with the grinding mill. Plows loed ahead of each roller direct the material upward and between the grinding rolls and the heavy alloy steel bull ring where it is ground to size.

What are the differences between ball mill and rod mill ...

Mar 08, 2021 · Grinding Medium of rod mill Grinding medium of rod mill The rod of diameter from 50 to 100 mm is often used as the grinding medium, and the filling rate of rod mill is 35% to 45%, while filling rate of ball mill is 40% to 50%. Rod is mainly made of several materials: A High carbon steel

Grinding Mills

Mar 20, 2017 · Different Types of Tumbling Mills Rod Mills:Mills loaded with rods as the grinding media are used for primary grinding of rocks and rods fall from a height and roll down the mill so the rods impart an impact force as well as an abrasive action.

Need wheel suggestions for surface grinding 174 stainless

Nov 26, 2015 · Iron freak has done about all you can do. The Silicon carbide wheel is better on stainless, especially austenitic alloys. But it's not always practical to go wheel shopping to grind one piece. You really need coolant on this, at least spray it with some, and let it .

Grinding Mills and Their Types – IspatGuru

Apr 09, 2015 · Grinding Mills and Their Types. satyendra; April 9, 2015; 1 Comment ; autogenous grinding, ball mill, grinding mills, hammer mill, rod mill, roller mill, SAG,; Grinding Mills and Their Types In various fields of the process industry, reduction of size of different materials is a basic unit operation.

List Of Types Of Grinding Mill

Nov 03, 2020 · Mill or grinding mill are machines used to reduce the size of rocks and stones in aggregates production, construction material recycling appliions, and in mining operations. SBM has designed, engineered and manufactured mills for more than 100 years.

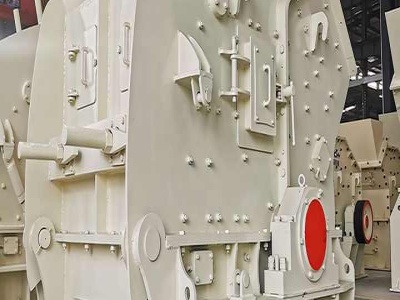

Hammermill Crushers | McLanahan

The HammerMaster is a highspeed mill noted for its ability to generate highquality aggregates, cubical in shape, with superior soundness. Available in three sizes, the HammerMaster is known for making excellent asphalt chip material, concrete stone, and general base material and road rock. This mill is also capable of making agricultural lime ...

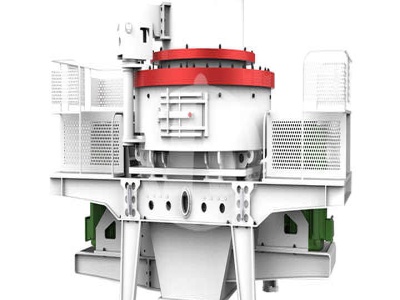

Product List

Grinding Equipment YCV Strength Hyper Pressure Grinder YGMQ4 European Type Grinding Mill HGM Series Micro Powder Mill LM Vertical Mill LUM Ultrafine Vertical Roller Mill; Sand Making 5X Sand Making Machine VSI Crusher XSD Sand Washer LSX Spiral Sand Washer HX Recovery of Fine Sand Device; Mobile Crusher Plants VK1 Coarse Crushing Portable Plant

Millstone

Millstones or mill stones are stones used in gristmills, for grinding wheat or other grains.. Millstones come in pairs: a convex stationary base known as the bedstone and a concave runner stone that rotates. The movement of the runner on top of the bedstone creates a "scissoring" action that grinds grain trapped between the stones.

Latest Posts

- أعمال الكسارة في اليمن

- gold werk maschinen und anlagenbau

- بيع كسارة الحجارة الثابتة

- عنصر منجم الفحم العملي

- آلة إفادة سعر الجرافيت

- كسارة منجم الذهب المتحدي

- معلمات اختيار كسارة الفك

- التعدين البوكسيت سحق وطحن

- أسعار البيع محطة كسارة

- تكسير النباتات العمانية

- الجزائر مصانع غسيل الذهب 50 tph

- الكرة اهتزازي طاحونة الموردين

- صورة مصنع طحن المعادن

- للبيع كسارة صخرة قديمة في الجزائر

- كسارة مخروطية متحركة 150 تيرا في الجزائر

- Mill For Quartz Crushing

- Type Jaw Mozambique Pe 80c

- Paragon Aluminium Roller Mill

- How To Make My Bridgeport Milling Machine Cnc For Z Axis

- Vertical Roller Mill Project

- Wet Cleaning And Dismantaling Dominica

- Gold Wash Plants Small Scale

- Principles Of Mineral Processing Torrent

- Mobile Stone Saudi Arabia Om85r

- Sanvick Used Cone Mongolia Track

- Kazakhstan And Ball Mill Rental

- Ball Mill Crushers Used In Guyana

- Ball Mill Machine For Chromite Ore

- Working Mechanism Of The Screen In Spain

- Nasa Olia Soya Crushing