Magnetic Separator For Iron Ore

MECHANICAL SEPARATION TECHNIQUES

•Concentrators –separation of large amount of magnetic feed product •Purifiion –removal of small amounts of magnetic particles from a large amount of non magnetic feed material. •Equipment –Wet and Dry types Concentration of ferromagnetic iron ores magnetite ores, iron ore other than magnetite, after preliminary conversion of

Beneficiation of an iron ore fines by magnetization ...

· These iron ores contain many detrimental impurities and are difficult to upgrade to make suitable concentrates for the blast furnace. In this paper, the beneficiation of a lowgrade hematite ore fines containing carbonates with magnetization roasting and magnetic separation was proposed and studied.

Magnetic Separation Process Of Iron Ore

Besides, the separation machines are devide into the dry and wet magnetic separation. Generally, iron ore with an iron content of 35% can increase iron content by 20% after magnetic separation. Such a combined process method, the ore utilization rate can reach 90%. In the process of magnetic separation, it saves water, reduces cost and pollution.

Modeling and Optimization of Vertical Pulsating High ...

Separator (VPHGMS), namely Magnetic Intensity, matrix Pulsation and revolution of the Ring (RPM) for the separation of Fe (Hematite) from a deslimed iron ore slimy sample was studied.

High Gradient Magnetic Separators (HGMS)

Outstanding separation selectivity. Outotec HGMS high gradient magnetic separators are designed to recover weakly magnetic material from nonmagnetic matter and can be used for many appliions including the processing of iron ores, rare earths and other weakly magnetic minerals, which are not normally treatable by ordinary magnetic ...

Model of Stabilization of the Quality of IronOre ...

· In the present paper, we reflect the main aim of control over the process of separation of iron ore in the course of wet magnetic dressing. We propose a procedure of deducing equations for the dependence of losses of the useful component in tailings and the mass fraction of magnetite iron in the concentrate on the water flow rate in the separator and the rotational speed of its drum. A ...

Iron Recovery from Bauxite Residue Through Reductive ...

the magnetic separation process has been examined by means of a wet highintensity magnetic separator, and the analyses have shown a marginal Fe enrichment in magnetic fraction in relation to the sinter. Keywords Bauxite residue Iron recovery Magnetic separation Roasting process Introduction Bauxite is an important ore that is widely used to ...

Magnetic Separator

Holmes, in Iron Ore, 2015. Utilization of subeconomic iron ores. As magnetic separators progress toward larger capacity, higher efficiency, and lower operating costs, some subeconomic iron ores .

Developments in the physical separation of iron ore ...

· They are also weakly magnetic. But if their magnetic susceptibilities are smaller than for oxidized iron ores, it is still possible to partially remove them from oxidized iron ores by magnetic separation. Lowgrade iron ore mined from the earth is usually composed of several minerals, desirable and undesirable.

Magnetic Separators

Permanent Magnetic Separators The science of magnetic separation has experienced extraordinary technological advancements over the past decade. As a consequence, new appliions and design concepts in magnetic separation have evolved. This has resulted in a wide variety of highly effective and efficient magnetic separator designs. In the past, a process engineer faced with a magnetic ...

Investigation of Efficiency of Magnetic Separation Methods ...

· In this research, the efficiency of magnetic separation methods for processing of a lowgrade iron pigments ore (red ochre) has been studied. Based on the mineralogical analyses (XRD), thin section and polish studies, the reserve is an iron sedimentary deposit with an average Fe grade of % The most valuable minerals are Hematite and Goethite and main gangue minerals are Calcite .

Magnetic Separator

Holmes, in Iron Ore, 2015. Utilization of subeconomic iron ores. As magnetic separators progress toward larger capacity, higher efficiency, and lower .

Comparing strategies for iron enrichment from Zn and Pb ...

The magnetic moment of the iron ore was as low as 1 emu/g, indiing that iron in the iron ore was hardly extracted by traditional magnetic separation. In RRP750 °C and RRP800 °C, magnetic moment increased to ~35 emu/g because hematite in the iron ore was efficiently converted into magnetite combined according to the phase analysis result ( Fig. 5 ).

High Precision, Advanced iron ore dry magnetic separator ...

iron ore dry magnetic separator machines up for sale are from the leading sellers and trusted manufacturers who assure outstanding quality and steady performance for a long time. These motoroperated. iron ore dry magnetic separator machines are available in various distinct models and their capacities may vary for each.

Magnetite Beneficiation: A Focus on Flowsheet Configuration

of magnetite ores using lowintensity magnetic separation. Although magnetite stoichiometrically contains the highest iron ( wt %) compared with all the other sources of iron, its lowgrade ore state usually contains low iron—magnetite ores loed in Australia usually contain iron grades between 14 and 45 wt % [4–6].

How Does a Magnetic Separator Work | GTEK Magnet

Magnetic Separators can be applied in mainly three ways: 1. Magnetic Separators for concentration or purifiion; Magnetic Separator can be applied in ore processing for separating magnetic materials, particular Iron. The advent of magnetic separation found favour in mineral processing for over 200 years ago. 2. Magnetic separators for product ...

Separator Magnets

Separator Magnets. Walker engineers and manufactures magnetic pulleys, drums, suspended magnetic separators, and eddycurrent separators designed for beneficiation, tramp iron removal, nonferrous metal recovery and various other separation processing appliions.

Magnetic Elutriation Technology for Clean and Efficient ...

MAGNETIC ELUTRIATION TECHNOLOGY FOR CLEAN AND EFFICIENT PROCESSING OF IRON ORE Project Fact Sheet This prototype of the 5R Research Magnetic Elutriator has demonstrated dramatic improve ments in separation performance over previous fullscale model of this elutriator is expected to achieve highly efficient separations, while greatly increasing ironore quality

Dense Media Separation – a Valuable Process for ...

· iron ore industries to produce either a final product or as a preconcentration step. Laboratory scale and pilot test work at the lve laboratory in Canada s demonstrated successful separation ha and upgrading of other minerals such as lead, .

ERG's SSGPO adding magnetic gravity separation to upgrade ...

· Kazakhstan iron ore mining company SokolovSarbai Mining Production Association JSC (SSGPO) which is part of Eurasian Resources Group (ERG), a leading diversified natural resources producer headquartered in Luxembourg, has completed the first stage of pilot tests of a magnetic gravity separator.

Magnetic separation studies for a low grade siliceous iron ...

· · 1. Introduction. Magnetic separation is an important beneficiation process and is usually adopted for ores of manganese, phosphate, titanium, chrome, tungsten, molybdenum, nickel, bauxite and niobiumtantalum ores in addition to iron ores,,,,,,,,,,,,,, .Magnetic separation methods were also carried out for the ferrochrome industry wastes such as the flue dust .

MAGNETIC SEPARATORS

Separation in fl uid (wet) High magnetic force separator (dry) Aluminum separator Used for a coolant separator (removal of iron particles in grinding fl uid, waste oil, cooling oil), drum separator (collection of iron ores, iron sand materials) and MAGFIN (removal of iron particles deposited in oil tanks). Magnetic drum Sludge (iron particles)

CHAPTER8 BENEFICIATION OF IRON ORES

MAGNETIC SEPARATION PRINCIPLES AND APPLICATION IN BENEFICIATION OF IRON ORES A. Das and S. Roy INTRODUCTION Magnetic Separation is one of the physical concentration processes that utilizes the differences in magnetic properties of various minerals present in the ore body.

Latest Posts

- بناء الكسارات الحجرية

- كسارة الحجارة ناكاياما مصر

- الحجر سحق آلة مصنعين في مصر

- كسارات سفيدالا الدورانية

- آلة غسل الرمال للبيع في المملكة العربية السعودية

- محطم النحاس خامات

- قائمة كسارة خام الحديد في keonjhar

- حساب البريد الإلكتروني الأبعاد دي أم موينهو دي مارتيلوس

- محجر كسارة نوعية جيدة معدات كسارة الفك

- فصل المعادن من نفاياتها

- استكمال محطة معالجة الذهب المحمول في الجزائر

- مستقبل صناعة تكسير الحجارة

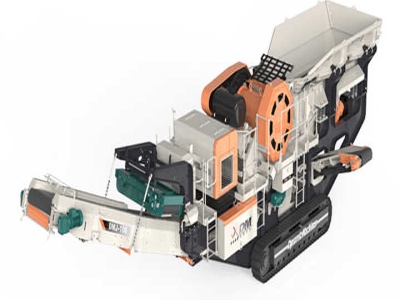

- كسارة متنقلة المحرز في عمان للبيع

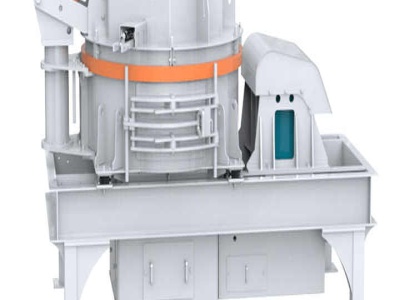

- أسعار مطحنة في المغرب

- الشركة المصنعة لمعدات صنع الحجر الرملي hyderabad

- Costa Rica Design Pinscrusher Design Plant

- Screening And Crushing Costa Rica Pdf

- Tone Spain To Clinker Plant

- Used Jaw Mobile Costa Rica In Uae

- Manufacturers Of Crushing Armenia In Armenia

- Universal Milling Machine Price List

- Jaw Portugal Parts Name With Photos

- Grinding Aids In Raymond Mills

- Portugal Plant Spherical Roller Bearings

- Sudan Manufacturer 60tph In Sudan

- the Philippines Grinding Mill Pdf

- Mini Guyana Plants

- Suriname Calcination Vertical Shaft Plant Flowsheet

- Bentonite Minerals Pulverizer Machine

- Construction Waste Disposal Plant Sri Lanka