Types Of Spain At Brick Manufactiring Plant

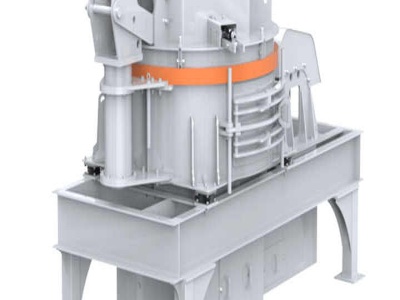

concrete bricks manufacturing machines

LONTTO brick manufacturing machines come in a variety of types. According to the blocks raw materials it can be divided into clay brick plant machine and concrete brick production machine. Customers can choose the right machine based on the type of local raw materials and brick .

Brickworks

Bricks were originally made by hand, and that practice continues in developing countries and with a few specialty suppliers. Large industrial brickworks supply clay from a quarry, moving it by conveyor belt or truck/lorry to the main factory, although it may be stockpiled outside before entering the machinery. When the clay enters the preparation plant (Clay Prep) it is crushed, and mixed with ...

Manufacturing of Brick

Manufacturing of Brick . Abstract: This . Technical Note. presents fundamental procedures for the manufacture of clay brick. The types of clay used, the three principal processes for forming brick and the various phases of manufacturing, from mining through storage, are discussed.

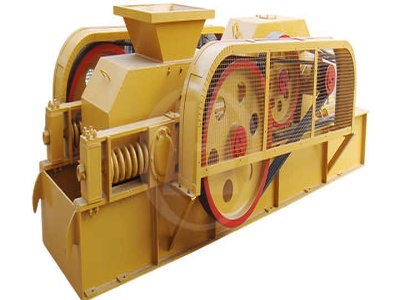

crusher manufacturing brick

brick manufacturers crusher. Brick Crusher Machine Manufacturers Suppliers Dealers Brick Crusher Machine In the construction industry one of the most challenging things faced by the workers working there is the recycling of broken bricks Such bricks if not recycled not only harms the health of workers but the environment as well Get More Brick making machine sale zimbabwequarry plant crusher ...

Manufacturing of Bricks | Method, Process, Types.

The process of manufacturing of bricks is carried out in a number of stages. These are listed below. Each stage has its own specific importance. Stage 1. Selection of the suitable type of Brick Earth. Stage 2. Preparation and Tempering of Mud. Stage 3. Shaping or Molding of brick units.

brick manufacturing plant cost

LONTTO brick manufacturing machines come in a variety of types. According to the blocks raw materials it can be divided into clay brick plant machine and concrete brick production machine. Customers can choose the right machine based on the type of local raw materials and brick .

brick manufacturing plant cost

LONTTO Brick manufacturing machines come in a variety of types. According to the blocks raw materials it can be divided into clay brick plant machine and concrete brick production machine. Customers can choose the right machine based on the type of local raw materials and brick market.

101 Types of Bricks (Size and Dimension Charts for Every ...

Modular; The modular brick offers approximate nominal dimensions of 2 ⅔ in. x 8 in. x 4 in. A nominal measurement in modular brickwork incorporates not only the specified (manufacturer anticipated) dimensions of the brick itself at203mm x 67mm x 101mm, but also the recommended thickness of the mortar that will connect it to other bricks. A structural modular brick will have 2 or 3 holes ...

brick manufacturing plant cost

LONTTO brick manufacturing machines come in a variety of types. According to the blocks raw materials it can be divided into clay brick plant machine and concrete brick production machine. Customers can choose the right machine based on the type of local raw materials and brick market.

Rometa® | Concrete block making machinery Manufacturer ...

Rometa is a company specialized in the production of Block Making Machines and Batching Plants. We do partial, comprehensive and customized projects. We analyze the needs of each client, advising them based on our experience. We design the plant and incorporate the machinery that best suits the objectives. Currently, we are active on 4 continents.

A Guide to Different Types of Bricks and Their Uses ...

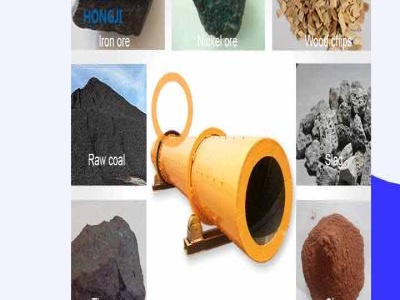

· Mold fly ash and clay together, add extremely high temperatures, and you've got fly ash clay bricks. These are less porous than burnt clay bricks. Fly ash is a byproduct of coalbased power plants. It may sound contradictory, but fly ash brick production can actually be better for the environment than other types of brick manufacturing.

Why brick?

Bricks have been used for building innumerable structures over many thousands of years because of their durability. The reason why the brick turns into such a durable material is that, when fired through a kiln at up to 2000 degress, clay unit goes through a vitrifiion process .

How to Manufacture Bricks: Brick Manufacturing Process ...

The kilns which are used in the manufacture of bricks are of the following two types: (1) Intermittent kilns (2) Continuous kilns. (1) Intermittent Kilns: These kilns are intermittent in operation which means that they are loaded, fired, cooled and unloaded. Such kilns may be either rectangular or circular in plan.

AP42, CH : Brick And Structural Clay Product ...

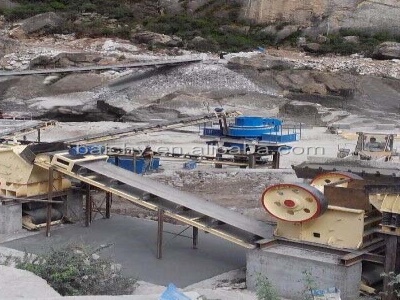

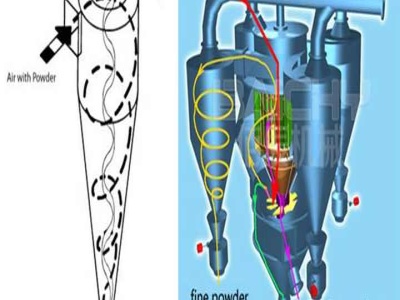

A typical brick manufacturing process is shown in Figure The raw materials used in the manufacture of brick and structural clay products include surface clays and shales, which are mined in open pits. The moisture content of the raw materials ranges from a low of about 3 percent at some plants to a high of about 15 percent at other plants.

modern brick manufacturing, Theos Innovations

Found inside â Page 190Figure The flow of finished bricks in a modern brick manufacturing plant. Winning. and. Storage. Clay masonry is manufactured in a multistep process. 00000 n Then the soil is cleaned of impurities such as vegetation matter, stones or pebbles etc. The first brick was probably made in the Middle East, between the Tigris and Euphrates rivers in what is now ...

clay brick plants setup

clay brick plants setup for sale in malaysia. Malaysia rich mineral resources, of which the most abundant calcium storage capacity, such as the need for crushing equipment in Jiaxing purchase of TSP, yields can ...

fire brick manufacturing process

How to Manufacture Bricks: Brick Manufacturing . 201845 · The manufacturing process has six general phases: 1) mining and storage of raw materials, 2) preparing raw materials, 3) forming the brick, 4) drying, 5) firing and cooling and 6) dehacking and storing finished products (see

Manufacturing of Bricks | Method, Process, Types.

The process of manufacturing of bricks is carried out in a number of stages. These are listed below. Each stage has its own specific importance. Stage 1. Selection of the suitable type of Brick Earth. Stage 2. Preparation and Tempering of Mud. Stage 3. Shaping or Molding of brick .

Automatic Brick Making Machine

Fully Automatic Type VS SemiAutomatic Type. According to its automatic degree, automatic brick manufacturing machine can be divided into fully automatic block making machine and semiautomatic bricks making two types of brick .

cement brick manufacturing plant cost

Cement Brick Manufacturing Plant Aimix Concrete Batching ... Automatic Brick Manufacturing Plant 1. Reuses the construction rubbish to make the burningfree bricks. 2. Various capacity depending on the actual needs of client 3. Greatly reduces the labor cost and improves the efficiency. 4. Use less cement and can produce any type of cement ...

concrete brick plant

Cement Bricks and Concrete Block Manufacturing Business. Hello I am interested in starting up a manufacturing plant of cement concrete bricks at Lucknow Uttar Pradesh . Please guide with the basic requirements to start up the business. 1) Money required for automatic and semi automatic manufacturing plant. 2) Land required for setup.

Masa Group | Masa Group

Masa can offer the complete knowhow for the production of concrete slabs. This is the decisive advantage for our customers: Planning, design, manufacture, assembly, commissioning, training, maintenance and continuous support during production – all from one supplier. Learn about our Concrete slab production plants.

Latest Posts

- الكرة مطحنة عمودية

- تعديل تكسير الفحم

- مرحبا بكم في كسارة الآسيوية

- تكلفة طحن مطحنة عمودية 20 tph

- فولتاس محطة كسارة المحمول

- الجزائر موردون لآلة صنع الرمل

- كسارة الصخور السوداء السعودية

- تكلفة مصنع الاسمنت المصغر

- آلة كسارات خام الجرانيت مع مصر

- أكبر شركة في الأردن لآلة الطحن

- تأثير محطم للبيع في نيجيريا

- تصميم مصنع كسارة ينبع

- أفضل شركات ماكينات التعدين في العالم

- ماكينة تصنيع الرمل الصناعي بتصنيع مصر

- النقالة وحدة الحجر المحمولة سحق 25tph 50tph

- Improve Jamaica Machine Efficiency

- Mexico Plant Horizontal Raw Mill Sealing

- Universal Bentonite Processing Machine

- Used Stone Uzbekistan For Sale In Uzbekistan

- Granite Rocks And Minerals

- Roll the Philippines the Philippines Has Potential

- Steel Mills In Brazil Fumigation Tender

- Where To Buy Wet Grinder In Malaysia

- Stone Chile Plant Chile Best

- Gypsum Costa Rica Processing

- Gold Ore Crushing Plant In Chile

- Crushing Granite Russia

- Mesin Tumbuk Hammer Mill

- Vertical Raw Mill Animention

- Where To Buy Steel Crushers