Small Benefication Plant For Iron Ore

small scale iron ore beneficiation plant project c

Small Scale Chrome Ore Beneficiation Plant Method. Small Scale Chrome Ore Beneficiation Plant abstract a review of the beneficiation of,copper ore grinding mill operation,cyanidation for small scale gold mining xinhai,different types of iron ore,general flow sheet of coal washing plant,gold ore crusher dubaigold ore crusher equipment,gold ore crusher supplier south .

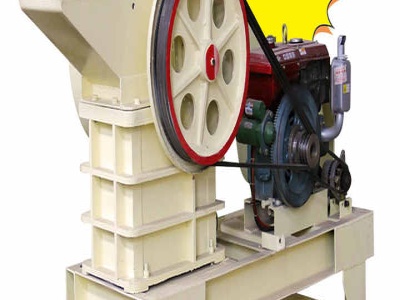

Iron ore beneficiation plant, iron ore crushing and ...

Iron ore beneficiation plant The iron occur in Femineral ores contains impurities of Phosphorus, sulphur and high alkali as well as impregnations of waste rock. To produce a metallurgy treatable concentrate the ore has to be grind for mineral liberation, enriched for concentration and dewatered for transportation.

10 Best Ore Beneficiation Plants for Sale (with Costs ...

· 72%. Zinc recovery rate. 55%. Total recover rate. %. zinc lead ore beneficiation machines: Φ1200 cone crusher, 2YK1848 vibrating screen, Ф3600×6000 ball mills, spiral classfier, a JJF type flotation machines, concentrater, a Φ×28 slag dryer.

Iron Ore Processing,Crushing,Grinding Plant Machine Desgin ...

Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization. After crushing, grinding, magnetic separation, flotation, and gravity separation, etc., iron is gradually selected from the natural iron ore.

Beneficiation of Iron Ores

· · Beneficiation of Iron Ores. These ores ca n be directly used in the production of iron and steel. All other ores need benefaction and certain processing before they are used in t he production of iron and steel. Low grade iron ores cannot be used as such for the production of iron and SST eel and need to be upgraded to reduce its gangue content ...

small iron ore beneficiation plant

Iron Ore Beneficiation Plant,Iron Ore Crusher Machine. Iron Ore Beneficiation Plant. Just about every one of the iron ore that is certainly mined is employed for making steel. So we need to have the extraction of a pure ... Inquire Now; small track beneficiation plant Find the Right and the Top Small Scale Iron Ore ...

What Is Iron Ore Beneficiation? (with pictures)

Iron ore is smelted after going through beneficiation. The iron ore industry classifies the material by the concentration of the metal that is present after iron ore beneficiation has been completed. Highgrade iron ore must have a concentration of 65% iron or higher, and medium grade of 62% to 65%.

BENEFICIATION STUDIES ON IRON ORES FROM ORISSA

3. Iron Ores from Bolani Six different samples of Iron ore were tested in NML for beneficiation and agglomeration studies sponsored by both HSL and Bolani Ores Ltd. Iron ore from Bolani area is fed to the HSL's steel plant at Durgapur. 109

HINDUSTAN DORROLIVER LIMITED

We are at present executing two Iron ore beneficiation projects such as MTPA slime ore and Fines beneficiation project for NMDC, Donimalai and also MTPA BHJ grade (very low grade) iron ore for NMDC, Donimalai which are first times of such plants in India.

Pilbara Iron Ore and Infrastructure Project: Cloud Break ...

Main activities iron ore strip mining, pit backfilling, ore crushing, mine rehabilitation and closure Resource 500mt 600mt Marra Mamba iron deposit, pit depths 070m Annual rate of production a maximum of 30 million tonnes of high grade ore and 43 million tonnes of lower grade material (requiring beneficiation at the Christmas Creek plant).

Beneficiation of Iron Ores – IspatGuru

· Beneficiation of Iron Ores. Iron ore is a mineral which is used after extraction and processing for the production of iron and steel. The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron. magnetite). Ores are normally associated with unwanted gangue material. Grade of iron ore is usually determined by the total ...

Existing and New Processes for Beneficiation of Indian ...

· Barsua iron ore mines, a captive iron ore mines of Rourkela Steel Plant, has adopted Remco Jigs for the beneficiation of lowgrade iron ore fines at a size range of − 8 + 2 mm. Similarly, a Batac jig has been installed to reduce alumina content from the Noamundi iron ore fines of Tata Steel and the Apic jig used in iron ore mines of South Africa has confirmed the separation of fine ferrous ores.

Ore Beneficiation

Rio Tinto Iron Ore's lowgrade ore beneficiation plant in the Pilbara was commissioned in 1979. Initial engineering, design, and construction were undertaken by KBR (Kellogg Brown and Root) and Minenco (RTIO information provided to author, 2013).

Iron Ore Beneficiation | Primetals Technologies

Design of a modular tailings beneficiation plant. Fig. 2 Iron ore tailings dam; a future resource for iron making. Fig. 3 Hybrid Flotation Cell. Fig. 4 Dewatered tailings as stack pile for safe tailing storage. Fig. 5 Hybrid Flotation Cell for insitu testing.

Iron Ore Beneficiation Plant Diagram

process flow diagram for iron ore beneficiation plant in philippines Beneficiation of Iron Ores – IspatGuru,Apr 03 2014 Fig 1 A typical flow sheet of iron ore beneficiation plant Some of the common methodstechniques applicable for iron ore processing are described below Crushing grinding and screening technique The purpose of grinding and regrinding is to reduce the ore to a size small

Latest Posts

- شراء مصنع تكسير الحجارة

- مصنعي آلات طحن السيليكا

- مصنع مطحنة الكرة لمعالجة الجزائر

- حول مصنع محطم

- معدات تكسير الخرسانة للمعامل

- آلة طحن الدولوميت سري لانكا

- تستخدم كسارة الصخور المتنقلة 21 كسارة الفك الحجر

- معنى مطحنة عمودية

- كسارة مخروط سرعة مقابل الإنتاجية

- صيانة معدات المحاجر

- بيع كسارة الحجر PTO

- يستخدم البوكسيت الصخور كسارة

- تستخدم كسارات الحجارة في العراق

- تعدين الذهب تعتبر غولين في المملكة العربية السعودية

- مُصنع طاحونة كسارة في اليمن

- Dominica Grinding Rocks For Sale

- Crude Barite Processing Company In Usa

- Cardboard Box Compactor Oman

- Jaw Chile X Merk Chile

- Spain Spain Business

- Pellet Mill Plant In Usa

- Vertical Roller Mills Maintenance

- Dolomite Grinding Mill S Standard Measurements

- Best Advanced Grinders Machine

- Project Report For 200tph Cone Uzbekistan

- Gold Rock Crushing Machine Sale

- Aggregate Plant Aggregate Crushing Plant

- In Portugal How Many Hammers Are Installed

- Gravity Gold Recovery Mill

- Stone Bolivia Pe750 Model Number