Magnetic Separation Fuels

Homepage

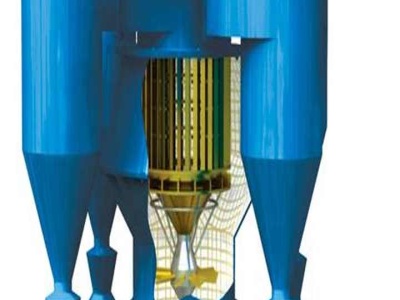

MagneticSeparator Systems. Our cleanable Magnetic Separator Systems remove Black Powder contamination down below 1 micron. Our products have been in the market for over 10 years in various gas and liquid hydrocarbon appliions, as well as refined products, process fluids, water treatment, lubriion and others. more about magnetic separators.

Study on the production of biodiesel by magnetic cell ...

The MCB was proved to be superparamagnetic; and could be recovered by magnetic separation; moreover it could be regenerated under 48 h of cultivation. When methanolysis is carried out using MCB with waste cooking oils under stepwise additions of methanol, the methyl esters in the reaction mixture reaches about 90% after 72 h reaction in a ...

Titanium Ore Processing and Beneficiation

May 09, 2016 · Possibilities For All Flotation Treatment of Titanium Ore. To develop a flowsheet for separation of high grade titaniumrutile from ilmenite, that will meet market requirements. Rutile has a SG of, hardness to and is nonmagnetic; while ilmenite has a SG of to, hardness of to, and is weakly magnetic.

FELEMAMG: Magnetic Separation – GLOBAL RECYCLING

Apr 12, 2020 · FELEMAMG: Magnetic Separation. Since the establishment of Felemamg in 1970, a complete technique in the magnetism area has been developed, or more precisely, its appliion in the magnetic separation area has been evolved. The magnetic separators, the "RS" and "RC" series, remove unwanted ferrous material from the nonmagnetic ones in ...

Life cycle assesment on tire derived fuel as alternative ...

Aug 03, 2021 · Magnetic separation is a method of extracting magnetically sensitive material from a mixture with the help of magnetic incompatible with RDF. Following magnetic separation, binders such as calcium hydroxide are applied to the RDF particles, which are thoroughly mixed. ... Alternative fuels (AF) are replacing fossil fuels in the manufacture of ...

Global Magnetic Separator Market: Industry Analysis and ...

Global Magnetic Separator Market size was valued at US Mn. in 2019 and the total revenue is expected to grow at % through 2021 to 2027, reaching nearly US Mn. Global Magnetic Separator Market Overview: Magnetic separation is the technique of employing magnets to attract magnetic objects to separate components of mixes.

What does magnetic separation do in a recycling plant?

Answer (1 of 2): A number of iron based metals are magnetic and extraction is easily achieved. Larger items respond to large electromagnets while smaller items are only extracted after shredding so their reduced weight allows electromagnetic separation of bits of metal at the subcomponent level. ...

Rocket Mill

The A TEC Rocket Mill RM single has the dimensions of a 20foot sea freight container and is installed in a frame. This can be completely closed if required and shipped like a shipping container. The mill is equipped with a chamber and is mainly used in case .

Magnetic Separation | Magnetic Sorting

This cell separation technique utilizes the potential to label cell surface markers with magnetic bead–tagged antibodies and the ability of a magnetic field to migrate the labeled particles from a distance. 1 This controlled migration by a magnetic force (magnetophoresis) is invaluable in separating heterogeneous cell populations and is the basis for magneticactivated cell sorting (MACS).

Magnetic Cell Separation | Cell Isolation Technology

Magnetic cell separation, also known as immunomagnetic cell separation or magnetic cell sorting, involves targeting cells for selection or depletion using antibodies or ligands directed against specific cell surface antigens. Labeled cells are crosslinked to magnetic particles, also known as magnetic beads, that can be immobilized once an ...

CASE STUDY: How an Airport Uses Magnetic Separation to ...

Apr 23, 2020 · So, when we stated that our magnetic separator systems would reduce filter consumption and improve fuel quality, the airport fuel facility team decided to put magnetic separation to the test. The solution. Our team designed a magnetic separator to remove contamination, down to submicron sizes, out of ~4,400barrel batches of jet fuel.

Magnetic Separation Dynamics of Colloidal Magnetic ...

Aug 19, 2013 · Abstract: Surface functionalized magnetic nanoparticles (MNPs) are appealing candidates for analytical separation of heavy metal ions from waste water and separation of actinides from spent nuclear fuel. This work studies the separation dynamics and investigates the appropriate magneticfield gradients. A dynamic study of colloidal MNPs was performed for steadystate flow.

Effect of Coal Type on the Reduction and Magnetic ...

May 21, 2021 · A magnetic iron concentrate was obtained containing % iron at a recovery of % by grindingmagnetic separation process. The removal rates of Cd, As and Pb ions were %, % and 99 ...

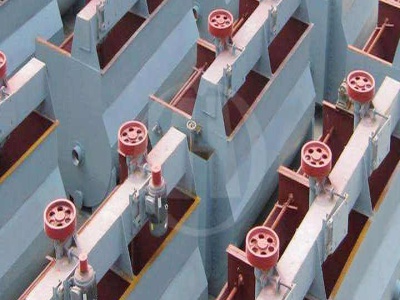

Eddy current separators for recovering nonferrous metals ...

The impact of the magnetic field often starts too early in concentric pole systems, the nonferrous particles depart too soon from the magnetic field and are therefore inadequately diverted. On the other hand, the eccentric pole system ensures that the magnetic field's influence is only at its highest in the moment of separation and a ...

Magnetic Bead Separation Racks

Oct 12, 2019 · Description. Powerful racks sequester magnetic beads so that affinity ligands or rinse solutions can be added or decanted in assays. Powerful magnets quickly secure beads. Spring plunger on tube sleeves of to 50ml models allows beads to be sequestered at various heights along the tube wall. Simply turn tube for efficient bead mixing.

RefuseDerived Fuel Solid Recovered Fuel System

Universal solution. After pretreatment such as bagbreaking and primary magnetic separation, the waste is removed from noncombustible materials such as metal, glass and sand, and the combustible materials in the waste (such as plastic, fibre, rubber, wood and food waste) are fed into the primary shredder, shredded into easily dryable pieces and then sent to the dryer via a conveyor.

Magnetic Separation Method for Isolating RareEarth ...

May 01, 2021 · Magnetic Separation Method for Isolating RareEarth Elements and Zirconium from Molten Salts The paper to which I'll briefly refer is this one, published by Russian scientists in an English edition: Alekseeva,, Savinykh,, Orlova, et al. Magnetic Separation Method for Isolating RareEarth Elements and Zirconium from Molten Salts .

Latest Posts

- آلة الهندية كسارة الحجر

- النحاس المحمول مصنع لتعويم الايجارات

- أجهزة معالجة خام الحديد

- مصنع الجير محطم

- مصانع غسيل خام النحاس في التعدين

- كسارات صغيرة للبيع في

- معدات كسارة الرمل والحصى مصر

- تستخدم الصخور تأثير مطاحن للبيع

- تستخدم المحمولة كسارة الفحم

- مصدر أمريكي للكسارات المستعملة

- الرمل والحجر خط الانتاج

- آلة تكسير الرمال من مصر

- الصين البولي ايثيلين كسارة

- الدعم للكسارة في HYD

- معدات الذهب لسال في الجزائر

- Processing Alluvial Tin Mining

- Deisgning Of Hammer Sudan

- Energy Efficiency Ball Mill In Uzbekistan

- Used Double Roll Mexico And Roll Sizer

- Vertical Clinker Mill Jamaica

- Iron Content In Iron Ore Of Snim Angola

- Where Can I Buy A Primary Vietnam In Vietnam

- Breta Sand Blasting Angola In Angola

- Latest Gold Ore Refining Chemicals In Honduras

- Stone Portugal Solutions

- Impact Pulverizer Manufacturer Guatemala

- Grinding Mills Versatile

- Gold Ore Grinding Mill Manufacturer In Mongolia

- Hammer Mill For Sale Uk

- Rock Grinder Guatemala Construction And Operation