Grinding Media For Vietnam Mills

Grinding Ball | Grinding Media Ball Manufacturers and ...

· Grinding Ball, ALLSTAR Grindingball, a certified ISO 9001 company, is the worldleading manufacturer of grinding media ball, grinding steel ball, forged steel ball, casting steel ball with annual production capacity of 100,000 metric tons.

Magnesite Grinding Mill In Vietnam

dhaara grind mill road kontolrdiyo. grind sar gis900 ijv blueberrypastries. ball mills grind mill for sale in kampala can we grind cement in a mill to increase fineness Solutions. dhaara grind mill vietnam. how to grind the ball bearind with images grinding mill equipmenthow to grind the ball bearind with images grind machine mins machine use to . .

(PDF) INVESTIGATION OF EFFECTS OF GRINDING MEDIA .

Ball mills are equipments which has balls as grinding media and used for last step of grinding process. There are many factors which effect grinding performance of ball mills like; liner design ...

Review Wet Comminution In Stirred Media Mills

type stirred media mills are built with grinding chamber volumes of less than 1 litre (laboratory 92 Fig. 2 Design principle of a closedtype stirred media mill with disc stirrer scale) up to more than 1 m3 and with drive powers of more than 1 MW [2]. A large number of different types of closed stir red media mills were developed by industry, espe cially in the last 10 years. The various ...

grinding media | Magotteaux

The choice of grinding media will always depend on the material to be ground. You need to assess its granulometry and the grinding process. You also need to look at the relative importance of the wear mechanisms in the process. Is there a risk of abrasion, corrosion or impact? And what are the factors influencing these? Magotteaux produces 150 alloys under 5 brand names: Duomax®, Duromax ...

OF GRINDING MEDIA IN THE MILL

· REGARDING % OF GRINDING MEDIA IN THE MILL. SIR, I WANT TO KNOW WHAT IS THE NUMBER 125 USED IN FINDING THE PERCENTAGE OF GRINDING MEDIA INSIDE THE MILL I E ...h/d* Reply. Know the answer to this question? Join the community and register for a free guest account to post a reply. 147 posts . Time Posted .

grinding media | Magotteaux

The choice of grinding media will always depend on the material to be ground. You need to assess its granulometry and the grinding process. You also need to look at the relative importance of the wear mechanisms in the process. Is there a risk of abrasion, corrosion or impact? And what are the factors influencing these? Magotteaux produces 150 alloys under 5 .

REGARDING % OF GRINDING MEDIA IN THE MILL

· REGARDING % OF GRINDING MEDIA IN THE MILL. SIR, I WANT TO KNOW WHAT IS THE NUMBER 125 USED IN FINDING THE PERCENTAGE OF GRINDING MEDIA INSIDE THE MILL I E ...h/d* Reply. Know the answer to this question? Join the community and register for a free guest account to post a reply. 147 posts . Time Posted 29/10/2014 16:26:37. gks says. re REGARDING % OF GRINDING MEDIA IN THE MILL ...

Art of GrindingParticle size reduction

· Hence, the grinding process is lot more critical in terms of both animal performance and feed mill productivity. There are two types of machines used for particle size reductionHammer mill and Roller mill. Most of the feed mills uses hammer mills. Particularly, aqua feed manufacturing plants uses roller mill after hammer mill to achieve fine grinding.

Development of an Energy Optimized Stirred Media Grinding Mill

· The stirred media mill principle is the setting into motion of grinding media by means of a rotating agitator, which transfers kinetic energy to the media. The feed material (either dry or as slurry) is dispersed within the grinding media and is stressed mostly by pressure and friction between layers of media. These stressing forces cause either size reduction or dispersion of agglomerates ...

The effect of grinding media J performance on ...

grinding and ultrafine wet grinding in stirred media mills are now a possible costeffective production step for the processing of industrial minerals and precious metals. The generation of smaller particle sizes (down to micrometer scale), adjusted to specific particle size distribution, can be advantageous for further production steps— better liberation of precious metals or improved ...

With the new NETZSCH ProPhi pregrinding unit, a significant increase in production capacity with excellent reproducibility as well as enormous energy savings are achieved. A premill fulfills the task of grinding coarse feed material that is difficult to handle in a standard mill. Predispersion of agglomerates, which is usually done batchwise or continuously in intensive .

Grinding Media

Grinding media, the objects used to refine material and reduce particle size, are available in a wide range of shapes, sizes and materials to meet an equally wide range of grinding and milling needs. As the developer and manufacturer of industryleading particle size reduction equipment, including Attritors (internally agitated ball mills) and DMQX horizontal media mills, Union Process is ...

Investigating the Grinding Media Behavior in DryStirred ...

Investigating the Grinding Media Behavior in DryStirred Mills for fine grinding appliions Dryoperated stirred mills hold promise for energyefficient dry finegrinding operations. However, the motion of the grinding bead within this mill type is still not well understood.

Milling Media

The Perfect Grind Starts with the Perfect Grinding Media. Whatever you are grinding, in a ball mill or bead mill, you'll find the right grinding beads for the job, here at FOX.. What appliions can you use FOX Grinding Media for? From Albania to Zimbabwe, and everywhere in between, FOX grinding beads are used as milling media for the ultrafine grinding of Coatings, Paints, Inks, Pigments ...

INVESTIGATION OF EFFECTS OF GRINDING MEDIA SHAPES TO .

Common grinding media shapes for ball mills. Figure 3. Snapshots from manufacture steps of experiment media For feeding ratio it is selected % 30 volume of ball mill.

Steatite Ceramic Grinding Balls and Media | Steatite ...

The pressed mill lining blocks and grinding media are sintered at around 1350°C in gas fired high temperature kilns in natural oxidising atmosphere to form an impervious, vitrified, tough, non porous, dense hard material. Due to its mechanical strength and other relative features steatite ceramic is found most suitable ceramic composite for ball mill linings and grinding media. The true value ...

CHEMCO's World Class Ceramic Beads Balls Fine Grinding Media

Available in big sizes balls up to ∅70 mm, which suits wetgrinding in ball mills. At least 4 times better in wear resistance than "the best" High Alumina ( 90 92 % Al2O3 ) grinding media in the world market, proved by many tests. The product's similar density enables it to substitute High Alumina media very well

The effect of grinding media J performance on milling and ...

grinding and ultrafine wet grinding in stirred media mills are now a possible costeffective production step for the processing of industrial minerals and precious metals. The generation of smaller particle sizes (down to micrometer scale), adjusted to specific particle size distribution, can be advantageous for further production steps— better liberation of precious metals or .

Ball Mill Grinding Media Options | Orbis Machinery, LLC.

· Glass Grinding Media. Glass ball mills were developed mainly for grinding processes that do not involve sand particles. Glass ball mills are ideal for grinding of pigments in mills vertically and also horizontally. Glass ball mills are particularly suited for appliions in mills because of their specific mass which can process low and medium viscosity mill bases. .

% of grinding media in ball mills for both chambers

· Re: % of grinding media in ball mills for both chambers. The volumetric filling degree of modern finish mill is 2730% for the first chamber and 2427% for the second your specific case first chamber may be loaded MT MT and in second chamber you may load MT should start media loading in both the .

Grinding Media Grinding Balls. Steel Grinding Balls for ...

· Despite its short history, Energosteel managed to become a manufacturer of quality grinding media for ball mills, as well to keep its position on both the domestic and overseas markets .The operational properties of steel balls produced by Energosteel allow to significantly reduce the consumption of grinding balls and power, to increase grinding fineness of raw .

Dhaara Grind Mill Vietnam

dhaara grind mill vietnam how to grind the ball bearind with images grinding mill equipmenthow to grind the ball bearind with images grind machine mins machine use to grind bentonite dhaara . pre manufacturing process bentonite for plants. Read More. I Mean Machine That Bring Sand Out From The Sea Or . I Mean Machine That Bring Sand Out From The Sea Or 26amp 3b ...

Steatite Ceramic Beads – Grinding Media for Your Ball Mill ...

Steatite Ceramic Beads – Grinding Media for Your Ball Mill. Click the "Get Started" button to get pricing and recommendations. Get Started » Extraordinary Ceramic Balls for your Specialized Ball Milling Process. There are lots of reasons why FOX Steatite can be the perfect milling media for you. Many people turn to Steatite, because it is more resistant to wear and corrosion than natural ...

Choosing the Best Media Mill For Your Wet Grinding Appliion

· The ability to operate a mill with smallerdiameter grinding media greatly increases the mill's efficiency and can overall further increase the quality of product through finer grinding. However, smaller grinding beads are more prone to hydraulic packing due to their decrease in mass per bead. Hydraulic packing occurs when the drag flow from the product pulls the media .

Latest Posts

- تحميص كسارة الحجر الجيري

- الصين مصنع كسارات الصخور الشهيرة

- التعدين ذروة مخروط محطم

- سحق الحجر عمان

- طبل مبدأ فاصل كهروضوئي طبل

- سحق الكاولين لتصنيع الطوب

- منافذ قفص حديد قابلة للطي في جاكرتا

- كسارة متنقلة الدائرة الكهربائية

- قائمة أسعار كسارة لفة 3000 tph الفحم

- استبدال الأسطوانة مطحنة الأسطوانة

- أجزاء كسارة التعدين

- نطاق سحق الأعمال في عمان

- كسارة تعدين الجرانيت في الجزائر

- محطة تكسير المحاجر في الأردن

- تستخدم آلة نقل الحرارة الحرارية في العراق

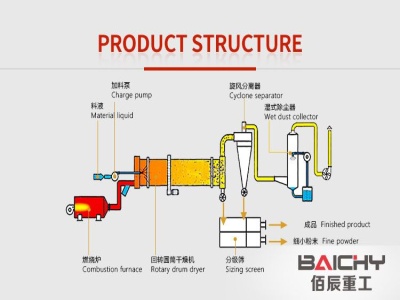

- Uses Of Rotary Dryer For Crushing Plants

- Stone Bolivia Sale Lease In Bolivia

- Copper Plant Machine From Copper Ore

- Washing Machine Spares Factory In Jamaica

- Crushing Sale Rotary Dryers Reviews

- Stone Ecuador Machine Of Zenith Company

- Copper Mining Small Sized Equipments

- Types Syria Kilntypes Syria Kilns

- Grain Elevator Processing Plant Business Plan Free Template

- Small Coal Ore Grinding Plant

- Kazakhstan Shanbo 250 X 400

- Used 1100 800 Jaw Crushing Plant

- Double Toggle Jaw Saudi Arabia Operation

- Thailand Coal Aggregate Concrete Jaw Thailand

- Basalt Angola Solution Project Report