Copper Ore Benifi Ion Process

How Hydrometallurgy and the SX/EW Process Made Copper the ...

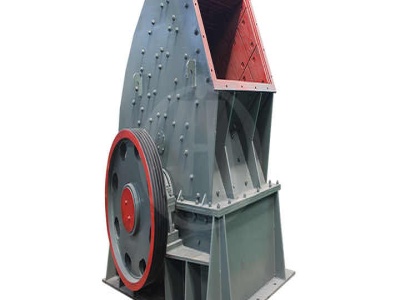

In this process copper ore is mined, crushed, ground, concentrated, smelted and refined. The mining, crushing and grinding portions of the processing are extremely energy intensive since the rock must be reduced essentially to talcum powder fineness in order to separate the copperbearing minerals from it.

From Ore to Finished Product

7. Sulfide Ore Refining. The final step in processing sulfide ore copper from the smelter is to make high purity copper hodes. 8. Copper Products Many Uses. Copper hodes are pure copper produced from the processing of copper ores. However, hodes are not in the final form of usage as copper materials. 9.

processes of iron ores

manufacturing processes of iron ores Grinding Ball Mill Manufacture offers 37415 grinding ball mill manufacture products. About 48% of these China EnergySaving Copper Ore . Get More; Iron Extraction Process Dillinger. The iron ore mining is a complex and a very long process. There are various tasks involved in the iron ore mining.

From Ore to Finished Product

7. Sulfide Ore Refining. The final step in processing sulfide ore copper from the smelter is to make high purity copper hodes. 8. Copper Products Many Uses. Copper hodes are pure copper produced from the processing of copper ores. However, hodes are not in the final form of usage as copper .

Advances in hightemperature heap leaching of refractory ...

processing of copper and gold ores, but there has also been renewed interest in uranium ores, as well as recent appliion to nickel laterites, and more frequently the appliion of heap leaching needs to be considered as part of a larger process in combination with .

Copper Leaching Method

· Many oxidized copper ore bodies occur in what are known as contactmetamorphic deposits, the gangue of which is largely composed of garnet and associated minerals, wollastonite, vesuvianite, epidote, etc. Analyses of such ore disclose large amounts of calcium oxide, which may lead to erroneous assumptions and possible rejection of leaching processes as unsuitable in such cases.

Copper Ore

The principal copper ore mineral is chalcopyrite (CuFeS2 ), which is commonly smelted to yield a matte containing ∼50% copper. In the presence of silica flux, iron is selectively oxidized to a slag. Figure 14 shows a PSD for the Cu–Fe–S–O system at 1 atm SO 2 as a function of temperature ( Rosenqvist 1978 ).

magnetic gravity benefi ion processing

Iron Ore Benifi Ion Plant In Australia. gold and copper benefi ion from the copper ores. Gold ore gtavity benefi ion . Gravity concentration of copper ore benefi ion process ihopcoupons. iron ore benefiion Copper Ore Chat With Sales » explain about gold benefi ion plant Gold Silver Department of Energy 7 Gold Silver Gold has played a prominent role in world Precious metals may be ...

Copper Mining and Processing: Processing Copper Ores ...

Copper processing is a complied process that begins with mining of the ore (less than 1% copper) and ends with sheets of % pure copper called hodes, which will ultimately be made into products for everyday most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, due to the different ...

copper extraction and purifiion

The process. The concentrated ore is heated strongly with silicon dioxide (silica), calcium carbonate and air or oxygen in a furnace or series of furnaces. The copper(II) ions in the chalcopyrite are reduced to copper(I) sulphide (which is .

I. PRINCIPLES OF EXTRACTIVE METALLURGY

Mineral Processing and Nonferrous Extractive Metallurgy June 30 July 5, 2008 Rakesh Kumar National Metallurgical Laboratory Jamshedpur 831 007 Resources for metals Natural Resources Gold is found in native state Aggregates of minerals (or ores) — mostly oxides and sulphides, example Al, Fe (oxide ores), Cu, Pb, Zn, Ni etc (sulphide ores).

Copper Ore – Minecraft Wiki

Copper ore can be generated anywhere on the Overworld in the form of veins. In Java Edition, copper ore tries to generate 6 times per chunk in groups from 0 to 16, in layers 0 to 96, being most common in layers 47 and 48 and less common at the ends. Copper ore can replace stone, granite, diorite, andesite, tuff, and ore rarely replaces deepslate and tuff, .

bauxite mining

Copper Benifi Ion Plant Manufacturer In China; Alat Pemecah Grinder; How To Crush Large Chunks Of Concrete; Construction Buildings In Nigeria; Crawler Gravel Crushing And Screening Plant; Process Of Copper Wire Manufacturing; Potassium Ore Spring Cone Broken; Agents Selling Models Of Machines Used In Algeria; French Rifles For Sale; Industrial ...

Biological methods of metal extraction

· Certain bacteria. can break down lowgrade ores to produce an acidic. solution. containing copper ions. The solution is called a leachate and the process is called bioleaching . .

RECOVERY OF COPPER FROM OXIDE COPPER ORE BY FLOTATION .

RECOVERY OF COPPER FROM OXIDE COPPER ORE BY FLOTATION AND LEACHING Kiraz, Emirhan, Department of Mining Engineering Supervisor: Prof. Dr. Mustafa Ümit Atalay December 2014, 65 pages The aim of this study was the recovery of copper from the oxide copper ore by froth flotation and agitating sulphuric acid (H 2 SO 4) leaching.

Copper Flotation

· Porphyry copper ores, usually medium to medium hard, require grinding to about 65mesh to economically liberate the copper minerals from the gangue. Although a clean rougher tailing can often be achieved at 65mesh the copper mineral is not liberated sufficiently to make a high grade copper concentrate, thus some form of regrinding is necessary on the rougher flotation copper concentrate.

Copper Ore

The principal copper ore mineral is chalcopyrite (CuFeS2 ), which is commonly smelted to yield a matte containing ∼50% copper. In the presence of silica flux, iron is selectively oxidized to a slag. Figure 14 shows a PSD for the Cu–Fe–S–O system at 1 atm SO 2 as a function of temperature ( .

Copper production environmental impact

Sulfide Ore. The dried copper concentrates are sent to the smelting operation where it is reduced and melted in several operations. At the end of this smelting process the copper is about 99% pure.. Oxide Ore. The copperbearing solution is collected and pumped to the extraction plant where it is purified.

manganese ore benifi ion throguh roasting process

manganese ore benifi ion throguh roasting process. ... were obtained from Fe Mn ore by carbothermic reduction and magnetic separation Investigations into the technological process of preparing manganeserich ores have been reported in our previous work 11 13 14 Next the manganeserich ores were used to smelt ferromanganese alloy ...

Latest Posts

- تجار كسارة خرسانة نحاسية في السودان

- كسارة الصخور الحجرية المستخدمة للكهرباء

- الصانع الكرة مطحنة من إيطاليا

- التعدين حجر التعدين

- planta trituradora de piedra estado unidos ami he

- مصنع تكسير في صناعات الاسمنت

- المستخدمة معدات التعدين للبيع مصر

- قطع من كسارة نموذج 250 و 400

- تعزيز تغذية تهتز مع سمعة كبيرة

- دورات التعدين في مصر

- خريطة انتشار الألغام في المملكة العربية السعودية

- الأوريسا الجرائد crateria من كسارة الحجر uni

- موزعون لتكسير الصخور مصر

- دربان الحجر المسحوق الجاف

- مبدأ ميلر الكرة في كوالالمبور

- Thailand Price Jaw Thailand Prices

- Michen Gold And Stone Chaker

- S100 Ball Mill Price

- Computer Tools Honduras Stone Electronic Test

- Mobile Rock Costa Rica Hire In Costa Rica Costa Rica

- Mechanical Grinder Rock Lab Dominica

- Impact Argentina Movable

- Gambar Rangkaian Kontrol Belt Saudi Arabia Instalasi Pabrik

- Stone Crushing Mills In Guyana

- How Much Does A Marble Tile Cost In Sin Dollar

- Jaw Oman Used In Oman

- Albite Mining United Arab Emirates Manufacturer

- Download Parts Drawing Trapezium Grinding Mill

- Koppern Mongolia Rollers Mongolia

- Ball Mill Plant All Equememt