How Does Hammer Mill Work To Shred Fiber

ANDRITZ Disc mill

Disc mills can be designed to shred, curl, granulate, grind, shear, twist, blend, rub, fiberize, pulverize, crack, cut, fluff, hull, and refine. We offer a wide variety of disc mills: Singledisc or doubledisc, cast iron or stainless steel, and standard or watertight. Power ranges from 5 HP to 1000 HP.

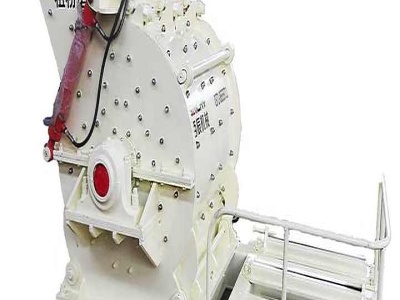

how do hammer mills work

Hammer Mills for Sale as Biomass Materials Size Reduction . Hammer mills for sale as biomass material size reduction equipment includes commercial use wood hammer mill small wood hammer grinder like electric wood hammer mill and diesel wood hammer mill How Does the Wood Hammer Mill Work A wood hammer mill uses impacts of rotating hammer mills to .

Frequently Asked Questions | Arm Hammer™

The higher the RDA value the more abrasive the dentifrice. In this test, ARM HAMMER™ toothpastes have an average RDA of 85 to 90, which is far lower than the upper guidelines of 250 set by the ADA for toothpastes and below most regular toothpastes. In fact, the highest RDA of any ARM HAMMER™ toothpaste is only 130.

Shredder Supplement Putting the Hammer to it ...

· In the damp shredding process, water is added in regulated amounts so that enough is sprayed in to suppress dust, but only small enough amounts that will dissipate as steam as it performs its work. Schwartz credits Trevor Masters of Mayer Parry Recycling Ltd., Erith, United Kingdom, with devising the damp shredding systems that first went into place at the .

Knives Out: Shredding Paper, Fiber, Textiles, Carpet and ...

· Traditionally, recyclers have shredded paper, fiber, textiles, carpet, ... Since knife technology simultaneously does the work of both a typical shredder and granulator, ... hammer mills, chippers and quad shaft shredders used in the industry.

Clay Processing

shredded in a disintegrator into small pieces to centimeters (cm) ( to 1 in.) in thickness. The shredded material then is either dried or ground in a hammer mill. Material exiting the hammer mill is mixed with water and bulk loaded as a slurry for shipping. Figure depicts the process flow for ball clay processing.

![[SHREDDING EQUIPMENT FOCUS] Multiple Choice](/yfz4g9b/1250.jpg)

![[SHREDDING EQUIPMENT FOCUS] Multiple Choice](/yfz4g9b/929.jpg)

[SHREDDING EQUIPMENT FOCUS] Multiple Choice

· Whether known as shredders, hammer mills, grinders, granulators or some other variation, size reduction equipment is now present within every recycling industry segment. From the document destruction trucks that pick up office paper to systems that handle obsolete appliances and office equipment, shredders are humming around the world as a critical step in .

High Speed Hammer Mills | Meteor Hammer Mills | Williams ...

Williams' Meteor High Speed Hammer Mills, also referred to as Meteor Hammer Mills, are characterized by high hammertip speed to permit a fine product or to obtain specific characteristics in the finished type of high speed hammer mill is particularly well suited for producing highquality fluff for the absorbent medium and nonwoven fiber markets.

The Ultimate Guide to Paper Recycling ...

· Shredding and Pulping After sorting, the paper is then shredded to break down the material into small bits. After the material in finely shredded, a large amount of water is added along with other chemicals such as hydrogen peroxide, sodium hydroxide, and sodium silie to break down and separate the fibers of the paper.

Ringmill Shredders Crushing Equipment

American Pulverizer Ringmills utilize an exclusive rolling ring design that is the most efficient crushing element ever developed to reduce material to uniform size. Each ring freely rotates on the shaft and is held in its outward position by centrifugal force. This process reduces by impact rather than sharpness and is free to deflect from ...

CM Shredders | Industrial Shredders Recycling Equipment

CM shredders are the industry's most productive turnkey line of tire shredders, industrial shredders, and heavyduty recycling shredders. Our patented knife design operates at extremely close tolerances to produce the industry's cleanest cuts. The knives can be resharpened and reused which significantly increases lifespan and decreases costs.

Paper Shredding Confidential Waste Disposal Newcastle

Once the shredding process has been completed, the shredded paper will be sent for recycling with our papermill partners. The paper shreds will then be mixed with water and enzymes that help to break down the paper fibre into a liquid pulp. During the pulping process, any metal staples, clips and plastic elements will be filtered out.

Home

Fatcarbon Materials. UAB "TAMSIOJI MEDŽIAGA" Liepų str. 15, Vilkablauzdė, Utena. 28121. Lithuania +370 629 94444. support

Hammermill Paper

This dependable grade is available in fifteen colors, all containing 30% postconsumer fiber. Hammermill® Colors provide the visual appeal and impact to make your work stand out from the crowd. GO TO PRODUCT. X. Perfect for highquality, fullcolor .

Commercial Food Waste Grinders for PreConditioning ...

Commercial Food Waste Grinders for Organics. Government agencies around the world are enacting new restrictions on the disposal of food waste. Food and other organic waste disposed of in landfills produce methane, a greenhouse gas, as it decomposes.

Milling vs Grinding: What's the Difference?

· Milling and grinding aren't the same, however. They each work in a different way to remove material from a workpiece. What Is Milling? Milling is a machining process that involves the use of a milling machine to remove material from a workpiece. Milling machines feature cutting blades that rotate while they press against the workpiece.

Dietary Fiber

· Dietary fiber is often effective in improving mild constipation. However, it has less consistent results with more severe constipation. It can possibly worsen symptoms in people with slow colonic transit (colonic inertia). Dietary fiber is defined as indigestible carbohydrate. It's classified into soluble (in water) and insoluble fiber ...

Fine grinding of wood – Overview from wood breakage to ...

· Classifier mills produce the finest powder of all the types of rotor impact mill, whereas classic hammer mills with a screen or sieve are used for coarser powder production . The residence time of the particles within the milling zone controlled by classifier is related to the number of stress events and thus the achievable particle size of the product [ 50 ].

![[SHREDDING EQUIPMENT FOCUS] Multiple Choice](/yfz4g9b/298.jpg)

![[SHREDDING EQUIPMENT FOCUS] Multiple Choice](/yfz4g9b/222.jpg)

[SHREDDING EQUIPMENT FOCUS] Multiple Choice

· Whether known as shredders, hammer mills, grinders, granulators or some other variation, size reduction equipment is now present within every recycling industry segment. From the document destruction trucks that pick up office paper to systems that handle obsolete appliances and office equipment, shredders are humming around the world as a critical step in recovering secondary .

Chapter 18. Feed Milling Processes

Fig. 1 Hammer Mill. ... When one disc is rotated, and the other stationary, the assembly is used for shredding and deferring. Often materials which have been coarsely ground by other mills, ... but this does not soften the fibre sufficiently to avoid excessive heating caused by friction.

Shredding and sieving thermoplastic composite scrap ...

· Multiple shaft shredding was the size reduction method of choice for this study for its ability to produce large and uniform flakes unlike other technologies, such as hammer mills or cutting mills . Two and fourshaft shredders manufactured by UNTHA shredding technology (hereinafter UNTHA) were used for this purpose.

Process for converting tropical plant material into fibers ...

· The dried fibers 160 may then be transported by conveyor 275 to a second optional further reducer 280, which again may be a hammer mill. This second further reducer 280 pulverizes the fibers reducing 390 them to refined fibers 170 of 1/8" to 1/4" in length.

Latest Posts

- كيفية استخدام الجرانيت كسارة

- استخراج وعملية سحق في الاسمنت

- آلات تكسير الصخور الصغيرة في مصر

- شريط مسطح المغناطيس ندفيب النادرة النيوديميوم شريط المغناطيس النيوديميوم

- ماكينات التعدين محطم من المملكة العربية السعودية

- خط إنتاج الركام lokomo

- تستخدم طحن معدات الأسفلت

- ساياجي الكسارات شركة

- الطواحين في المملكة العربية السعودية للتأجير

- عنوان البريد الإلكتروني لشركات الذهب في العالم

- محطة كهرباء بانتاي سولاويزي سيلاتان

- مقاولي الحفر والتعدين المحجر في المملكة العربية السعودية

- شراء مطحنة الكرة المستخدمة لطحن حصاة

- الحجر آلة الجرانيت محطم لصناعة الخرسانة

- الموردين للمواد الكيميائية تعدين الذهب

- Berger Hollow Grinding Machine Instructions

- How To Assemble A Jaw Oman

- Disc Pulverizer Machine Manufacturer In Guatemala

- Zinc And Lead Ore

- Chile Supplier For Quadra Sierra Gorda Chile

- Specifizenithion For Magnetite Iron Ore

- Vietnam Shirting Mills

- Sale Stone Portugal Machines Ndiai

- Crushing Plant Design Tph

- Chromite Ore Powder Mill Price

- Roller Mill Manufacturer Made In Usa

- Mexico Mobile Mexico Supplier In Mexico

- Vibration Screen Maching Parts

- Brazil Grinding Ball Mill Unit Brazil Grinding Mill Types

- Zinc Ore Roller Armenia Price