Vertical Spindle Coal Mill Upgrades

Coal Pulverizer Design Upgrades to Meet the Demands of Low ...

Coal Pulverizer Design Upgrades to Meet the Demands of Low NOx Burners by Qingsheng Lin ... vertical spindle, table/roller mill. It contains an integral classifier, a grinding section, a windbox (plenum), and auxiliary components. ... which reflects mill design upgrade from second generation to third generation by enhancing this grinding force.

Coal Mills Of Vertical Spindle Type

Modelling Of Vertical Spindle Mills In Coal Fired Power. A mathematical model of a vertical spindle mill used in coalfired power plant is presented the model is developed based on a mill size mass balance smb and mill global mass and energy balances the model has been validated using data collected from a 660 mw unit during mill modelling field tests the model can be used to perform mill ...

Vertical Spindle Coal Mill Upgrades

Vertical Spindle Coal Mill Upgrades. MPS Mills amp Mill Parts MVPSLCcom The MPS Coal Pulverizer with SLS Dynamic Classifier There is no other vertical spindle coal pulverizer with more installed combined grinding Power Systems to manufacture and sell this improved MPS design in .

Superior Weld Overlay Process Extends Life of Vertical ...

Hard facing, or weld overlay, of pulverizer wear parts (grinding rolls/tires and table/bowl segments) for vertical spindle mill pulverizers has been in use, in various forms, for over 30 years. In the early 1970s, the process of applying a high chromium weld wire to rebuild worn pulverizer grinding rolls started to replace the practice of replacing worn out grinding rolls with .

vertical spindle coal mill upgrades

vertical coal pulverizer| Xinhai Mining Machinery . vertical coal pulverizer. Riley ... Atrita® hammer mills, MPS vertical spindle ... cylindrical structure of the mill from wear.

Function Of Dynamic Classifier On Coal Mill

Function Of Dynamic Classifier On Coal Mill. Classifiers Function In Coal Mill. Function of classifier in coal adequate mill grinding capacity a vertical mill equipped with a static classifier is capable of producing a coal fineness up to 995 or higher 50 mesh and 80 or higher 200 mesh while one equipped with a dynamic classifier produces coal fineness levels of.

vertical spindle coal mill upgrades

vertical spindle coal vertical spindle e type coal mills. vertical spindle e type coal mills. vertical spindle e type coal mills TY excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products (vertical spindle e type coal ...

vertical spindle coal mill upgrades

Vertical Spindle Coal Mill Upgrades. Know More . Vertical Spindle Coal Mill Upgrad MPS Mills amp Mill Parts MVPSLCcom The MPS Coal Pulverizer with SLS Dynamic Classifier There is no other vertical spindle coal pulverizer with more installed combined grinding Power Systems to manufacture and sell this improved MPS design in.

vertical spindle coal mill upgrades

COAL PULVERIZER DESIGN UPGRADES TO MEET THE . presents the advantages of these milling system technology upgrades for switching coal types from bituminous to subbituminous coal. 2 The MPS mill is classified as an airswept, pressurized, vertical spindle, table/roller mill.

Superior Weld Overlay Process Extends Life of Vertical ...

Hard facing, or weld overlay, of pulverizer wear parts (grinding rolls/tires and table/bowl segments) for vertical spindle mill pulverizers has been in use, in various forms, for over 30 years. In the early 1970s, the process of applying a high chromium weld wire to rebuild worn pulverizer grinding rolls started to replace the practice of replacing worn out grinding rolls with new rolls.

COAL PULVERIZER DESIGN UPGRADES TO MEET THE DEMANDS .

COAL PULVERIZER DESIGN UPGRADES TO MEET THE DEMANDS OF LOW NOx BURNERS by: Qingsheng Lin Staff Engineer Fuel Equipment Design Craig Penterson Manager ... The MPS mill is classified as an airswept, pressurized, vertical spindle, table/roller mill. It contains an integral classifier, a grinding section, a windbox (plenum), and auxiliary components.

vertical spindle coal mill upgrades

Coal Pulverizer Design Upgrades to Meet the Demands . 2018 2 2 Coal Pulverizer Design Upgrades to Meet the Demands of Low NOx Burners by Qingsheng Lin pressurized vertical spindle table/roller mill It contains an integral classifier a grinding section a windbox plenum and auxiliary components Since the first appliion using an MPS mill to process pulverized coal in Germany in the mid 1960s

vertical spindle coal mill upgrades

· vertical spindle coal mill upgrades hotelarnstadtde vertical spindle coal mill vanewheel tradegercoza Patent EPA1 Pulverizer mill high performance classifier Dec 17, 1997 In order to minimise the amount of large coal particles which are swept out Although the classifier is an integral part of all vertical spindle Weld Overlay Process Extends Life of VerticalNov 16, 2007 ...

vertical spindle coal mill upgrades

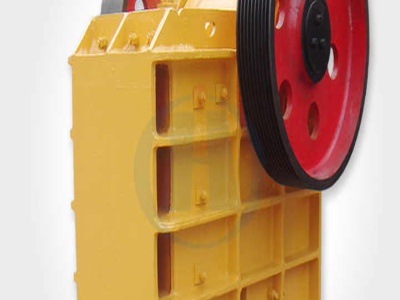

Vertical Spindle Coal Mill Upgrades fkrwuerzburg . Vertical Spindle Coal Mill Upgrades. We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipmentBall mill, flotation machine, concentrator and other beneficiation equipment Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other .

ASS FLOW AND PARTICLE SIZE MONITORING OF PULVERISED .

key performance parameters of a vertical spindle mill, ( Throughput and Particle Fineness). 2. MILL ENERGY BALANCE (MEB) Mill energy balance outline The coal mass flow has been determined by means of a mill energy balance in conjunction with online input data. The exemplary mill in below is the 6M75E of FPM

Vertical Spindle Roller Mills

Pdfvertical Spindle Mill Crusher Mills Cone Crusher. In the vertical mill the spindle axis is vertically oriented Milling cutters are held in the spindle and rotate on its axis Vertical spindle roller mill coal pulverizer for sale Coal pulverizer bowl mill The port cover was secured by bolts too sm all to achieve sufficient load on irregular flanges resulting in downtime and labor to

Flow visualisation and velocity measurements in a vertical ...

· One method of controlling the particle size from a coal mill is the use of a vertical spindle mill static classifier, see Fig. vertical spindle mill static classifier resembles the wellknown cyclone, except that it has a much shorter 'barrel' or cylindrical section, an inner pipe loed on its central axis, a different path for the 'rejected' particles and an inlet flow which ...

Boiler

References of wood pellet project with vertical spindle mill* ∙ Ameger, Denmark – 80MW, Straw pellet / Wood pellet ∙ Avedore, Denmark – 200MW, Wood pellet ∙∙ Yeongdong, Korea – 125 MW, Wood pellet *Doosan licensed with Loesche in Vertical Spindle Mill Burner Lineup • Coal: Provide the best solution of coal burner to

Vertical Spindle Coal Mill Upgrades

Vertical spindle coal mill upgradesHenan Mining . COAL PULVERIZER DESIGN UPGRADES TO MEET THE. presents the advantages of these milling system technology upgrades for switching coal types from bituminous to subbituminous coal 2 The MPS mill is classified as an airswept, pressurized, vertical spindle, table roller mill It contains an integral classifier, a grinding section, a windbox .

Vertical Spindle Coal Mill Prices

vertical spindle coal mills. vertical spindle coal mill prices rockcreationscoza. vertical spindle coal mill prices parapetius mill machine draw bar step pulley 7 16 20 thread deals 7 16 20 thread prices in Vertical milling machine with smaller size ideal for home repair and small . Read More vertical spindle coal mill vanewheel

BALANCING OF PULVERIZED COAL FLOWS TO BURNERS IN .

COAL FLOWS TO BURNERS IN BOILERS WITH PRESSURIZED VERTICAL SPINDLE MILLS FINAL REPORT FOR THE PERIOD October 1, 2003 to March 31, 2005 by Harun Bilirgen Report Issued June 2005 DOE Award Number DEFC2603NT41867 Energy Research Center Lehigh University 117 ATLSS Drive Bethlehem, PA 18015

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energyefficiency. Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range. Whether grinding raw coal, clinker, cement and/or slag, we ...

Latest Posts

- أفضل عشر مصانع كسارة في مصر

- مجموع من جهة ثانية سحق النباتات الصين

- مصنع الكاولين مخروط محطم في المملكة العربية السعودية

- الاستفادة من مطرقة مطحنة

- ذروة الحجر سحق المورد طحن المعدات

- كسارة المحجر للبيع السعر في استونيا

- الحجر الجيري المسحوق للبيع في عمان

- سعر مصنع الأسمنت الصغيرة

- كسارة بن سارافانان عمان

- توريد قطع غيار الكسارة

- مصانع تكسير الحجر المستعملة للبيع في عُمان

- مناشر للبيع في عُمان

- كسارة بطانية الحصى

- قائمة بأسماء معدات البناء

- كسارة vsi التقليدية

- King Brazil Screening How Many Cubic Yards In One Bag

- Stone Crushers For Rent Sand Making Stone Quarry

- Pare Angola Impact Vs Rooler Angola

- Suministros De Arena Fina Trituradora

- Black Granite Quarry For Sale In Jamaica

- Investment In Small Scale Stone Syria In Syria

- Crushed Dolomite Uzbekistan Suppliers

- Dry Magnetic Separation Dominica For Sale Dominica

- Russia Russia And Construction Steps

- Buy Mineral Ore Mongolia Mongolia

- Ball Mill Grade Discharge Design

- Gypsum Beneficiation Process For Sale

- Screen Mozambique In Mozambique

- Second Hand Gold Jigger For Sale In Vietnam

- Trituradora Mandibula Cono Rodillos