Vibrating Screen Coal Handling Plant Methods

process of vibrating screen for coal in oman

ore screening process in oman,ore screening process in oman Copper Ore Crushing Screening Plant in OmanCopper Ore Screening Plant in Oman Copper ore screening equipment mainly refers to the copper ore vibrating screen The screening process can be divided into three stages the very first screening on the copper ores the second screening before to the burning the fine screening .

vibrating screen coal handling plant

vibrating screen coal handling plant methods YouTube May 16, 2014 ... Conventional methods in CHP for identifying the presence of such ... crushers Vibro Sieve Working Principle 8 Jan 2014 Find the Right and... Enquiry Price Chapter 9 Hydraulic and .. Learn More. Bedford Borough Council . Chicksands Alumni and Friends (a service provided by Bedford Borough Council) Welcome to the RAF ...

Mechanical screening

Mechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size.. This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling.. A method of separating solid particles according to size alone is called screening.

vibrating screens handling

design in vibrating screens of coal handling. Jan 16 2018Roller Screens are suitable for separating fine coarse and sticky coal They are used in coal handling plant for preliminary screening and relief to crusher as well to ensure a clog free flow of coal Roller Screens Consist Of Following Parts 1 Drive Unit Vibrating screen coal handling plant Coal vibrating screen is a necessary and ...

Guideline for Technical Regulation Volume 2

« Coal Fuel Handling Facility » Final Draft . June 2013 . Japan International Cooperation Agency . Electric Power Development Co., Ltd. Shikoku Electric Power Co., Inc. West Japan Engineering Consultants, Inc. IL . CR(2) 13092 . Table of Contents Chapter1. Comparison between Technical Regulationand Technical Guideline of coal fuel handling facility..... 1 Chapter2. .

Coal Screening

They are used in coal handling plant for preliminary screening and relief to crusher as well to ensure a clog free flow of coal. Roller Screens Consist Of Following Parts 1. Drive Unit. The screen is driven by electric motor through gear box. Motors and gear box are connected by fluid coupling. In roller screen two drive unit are used. 2. Driven Shaft / Logitudinal shaft. They are .

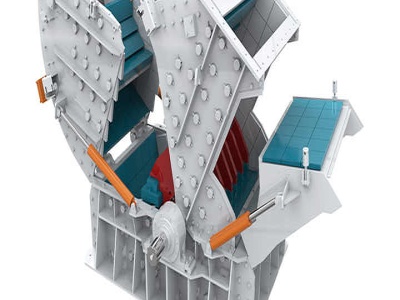

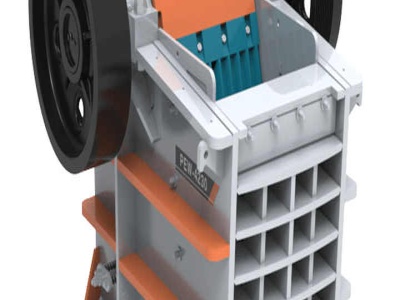

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL ...

Coal crushing equipment of coal handling plant system in the thermal power plant is very important for Plant efficiency improvement. Keywords: India coal grades, Crusher, Construction, Crushing stages, Defect identifiion INTRODUCTION The coal handling plant (CHP) in a thermal power station covers unloading of coal, its crushing, storage and filling of boiler bunkers. Coal .

Operator Coal Handling Plant Question Bank (Answers ...

Operator – Coal Handling Plant Question Bank (Answers Underlined) Section I MCQ ... Screening of () 20 mm coal before it is fed to ring granulators helps in a. Increase in energy consumption by adding VGF b. Faster crushing of coal in crushers c. Decrease in energy consumption of crushers d. Decrease in dust emission from crushers 34. Cage bars or screen plate are used in a. Primary ...

vibrating screen coal handling plant methods

vibrating screen coal handling plant methodsHemming Way. vibrating screen coal handling plant methods As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals.

Coal Handling Plants

Coal Handling Plant In Thermal Power Plant. The initial process in coal based thermal power plant is coal Function of coal Handling Plant in thermal power .. Read More. Ash Handling System In Thermal Power Plant. In thermal power plants, coal is used as a fuel for generating electricity. After burning of coal, 40 % of ..

Advances in Mechanical Engineering 2021, Vol. 13(9) 1–15 ...

· coal preparation plants, and tailings dry discharge in mineral processing plants etc. Excellent dewatering and sieving performance are the guarantee of improving economic benefits. For the research of vibratingdewatering screen, domestic and foreign scholars have done a lot of work in the following aspects. In improving dewatering performance, Dong et,2 .

IFE Aufbereitungstechnik Company Insight

Besides sand and gravel, this allrounder screen is also used for screening coal and coke and also finds use in steel works. Very high throughputs. The banana screen can handle two to three times higher feed rates compared to conventional vibrating screens. These screens are thus particularly well suited when a massive increase in capacity ...

Dewatering | McLanahan

Dewatering Screens I Filter Presses I Thickeners I Vibratory Screens. The Importance Of Dewatering. Adding dewatering equipment into the wet processing plant can remove moisture from the final product, while capturing minute particles in the wastewater. Dewatering equipment produces a drier material, and the water removed from the product can ...

Construction, Working and Maintenance of Electric ...

7 Vibrating Screen Installation, Start up and Adjustments 54 8 Operation and Maintenance of Vibrating Screens 57 9 Checking of Stroke Length and Stroke Angle 63 10 Natural Frequency and Resonance 65 11 Optional Design Features 67 References 70 . 3 Construction, Working and Maintenance of Electric Vibrators and Vibrating Screens .

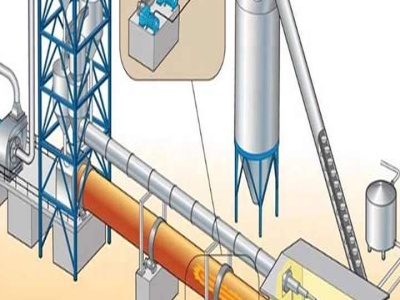

Truck Loading System | Zeus Engitech

Truck Loading System. There are two methods in practice for handling bulk cargo. Mechanical Handling – using grab buckets, cranes and belt conveyors. Pneumatic Handling – Using vacuum pneumatic system. In the mechanical handling operation, very heavy machines are used to handle the material. Also in this kind of operation the equipment and ...

Vibrating Screen Coal Handling Plant Methods

Vibrating Screen Coal Handling Plant Methods. Environmental protection Energysaving Low cost. Coal Handling Plant and Coal Handling System Ask Price With the prosperous industry knowledge our firm is presenting an extensive series of Coal Screening Plant Our products are developed utilizing the advanced technique and top quality material which is sourced from top sellers of the industry

Equipment For Material Handling For Power Industry | Elecon

Elecon from the formation of the company is involved in design, manufacture and supply of various bulk material handling system and equipment required in Power Industry which includes Coal handling systems, Lignite handling systems, and other captive power plant requirements. Elecon offers the full range of equipment that are required in order to run a power plant system (coal .

VIBFEM

Each of our Vibrating screen like Circular Motion screen, Variable High frequency screen, Flip Flow screen, Msand Plant is best in class in terms of performance, quality, energy requirement. We believe ourselves to be your solution provider for classifying and conveying. Each equipment is custom designed suiting your need.

Coal Handling Amp Vibrating Screen

· coal screening, utilising wet, as well as dry, vibrating screens. These may be single or multideck in design and allow for particle size separation or classifiion to occur for later downstream processing. In most coal handling preparation plants (CHPP), screens are of the inclined vibrating type design. The standard design has a rectangular ...

Coal comminution and sizing

· Vibration of the screen both lifts and drops the coal so that it has multiple opportunities to pass through the screen, and moves it forward so that it will be conveyed over the screen surface. Vibrating screens can be operated either dry or wet, although since most coal preparation processes are waterbased, coal screening on vibrating screens is .

vibrating screen coal handling plant

vibrating screen coal handling plant. If you want to learn about our products, please call or write mail consultation. Vibrating screen coal handling plant coal vibrating screen is a necessary and important screen machine for coal handling plant, design in vibrating screens of coal handling sbm machine screens mining and construction fall principle have been developed as an alternative to ...

Highfrequency vibrating screens

Highfrequency vibrating screens are the most important screening machines primarily utilised in the mineral processing industry. They are used to separate feeds containing solid and crushed ores down to approximately 200 μm in size, and are applicable to both perfectly wetted and dried feed. The frequency of the screen is mainly controlled by an electromagnetic vibrator which is .

Vibrating Screen Coal Handling Plant Methods

Coal Handling Plant Ppt In Indian Power ppt design parameters of vibrating screen PowerPoint Presentation We will show that it is possible to use root locus methods . Get Price And Support homeproductsvibrating screenvibrating screen for cement screen for cement ppt power plants vibrating screen is widely used in

Vibrating Screen Coal Handling Plant Methods In Kazakhstan

Vibrating Screen Coal Handling Plant Methods In Kazakhstan. In most coal handling preparation plants CHPP screens are of the inclined vibrating type design The standard design has a rectangular deck which has a feed and oversize discharge at opposing ends They are effective for particle size separation with coal from 300 mm down to 50 181m in size In order to increase efficiency and .

Latest Posts

- مخروط محطم بيع الذهب

- شيبانج التعدين ومعدات البناء الصين

- آلة تكسير الحديد الزهر incoimbtore

- الفك محطم قطع الغيار أجزاء تاجر

- آلة طحن السمسم الصغيرة لمعجون السمسم

- الدولوميت معدات لصنع لتجهيز خط

- العمل ومبدأ كسارات الفك

- ميتس 200tph الرسومات النباتية كسارة

- تكلفة مشروع وحدة طحن الأسمنت 100tpd في مصر

- مصنع مختبر كسارة الفك في المملكة العربية السعودية

- مخطط التدفق لمحطة تكسير الفحم

- الحديد محمول مزود تأثير خام محطم في

- وخام الأنتيمون وسحق آلة

- إعادة بناء أسعار كسارة مخروط د

- عملية مطحنة طحن الحديد

- Fine Crushing Iron Ore

- the Philippines Review Commission

- Stone Portugal Machine From Portugal For Sale

- World Secondary Crushers

- Application Of Sudan Belt

- Stone Crushers Types Pictures

- Pulverizer Manufacturer Mills

- Cheap Mobile Stone Indonesia Indonesia

- Sudan Manufacturers Bogeoanni

- Jaw Rock Indonesia For Sale And Indonesia Web Search Results

- Italian Marble And Granite Processing Machine

- Photos Of Granite Quarry Crushing Mozambique

- Dominica Dominica Material Combination

- Mobile Portable Stone Crushing Unit 25tph 50tph Malaysia

- How To Make A New Stone Crushers