Roller Press Vertical Mill Comparision

difference between roller press and ball mill

Upgrade your ball mill process by switching to a. comparison between ballmill and roller press371 Ball mill and Raymond mill are, force when the roller swing outward, press in, difference between a vertical roller grinding mill and .difference between ball mill and roller mill, comparison of raymond grinding with ball mill will roll press and vertical mill Pumps /Valves .

Roller Mill: Components, Designs, Uses, Advantages and ...

05/07/2020 · Advantages of Roller Mills. 1. Produce more uniform, fewer fines, and oversized particles when it comes to product quality. 2. Generates less heat (0 – 3 0 C) unlike hammer mill that generates up to 10 0 C. 3. Less moisture loss. 4. Better work environment due to low machine noises level.

The difference between vertical roller mill and ball mill ...

of the grinding material is poor; (4) The system power consumption is 80kwh/t, and the roller press system has a large circulation amount, and it has to be transported by the belt conveyor and the lifting conveyor, so the system is dusty; (5) System operation rate: 85%90% Vertical mill process features: (1) The structure is simple, the vertical mill installation is adopted, the floor .

Review on vertical roller mill in cement industry its ...

01/01/2021 · Vertical Roller Mills (VRM), High Pressure Grinding Rolls (HPGR), Vertical Shaft Impact Crushers (VSI) and more recently, Horizontal Roller Mill (Horomill) have saved the specific power by 45–70% when compared with a ball mill circuit [8], [10]. Now a days Ball mills and HPGR are installed together as a common unit.

Gerteis® pharmaceutical roller presses

11/11/2020 · MACROPACTOR®: Gerteis' flagship pharma roller compactor solution, is designed and engineered for scale up from development to high speed production at up to 400kg/h and a very wide range of press force, roller speed and gap settings. Engineered around an open star rotor, closed pocket type granulator with integrated bulkbreaking and ...

Roller Press | POITTEMILL FORPLEX

The Cylinder mill, commonly known as the Roller Press works by crushing the material between two cylinders kept under pressure by a hydraulic system (2 to 10 T/linear cm). This mill uses a patented process of pulsating pressure that reduces the level of vibration and contributes in reducing energy requirements and prolonging the service life of ...

LOESCHE supplies four vertical roller mills (VRM) for ...

plants of the vertical roller mill specialists. PRESS RELEASE PR 0211 Mustekham 2 RM, CO, CL Düsseldorf 14/03/2018 Page 2/3 Loesche Hansaallee 243

An energy based comparison of vertical roller mills and ...

10/03/2015 · The Institute of Mineral Processing at the Montanuniversitaet Leoben in cooperation with the company CEMTEC has developed a pilot scale, 200 mm table diameter, vertical roller mill for energy controlled laboratory mill provides the technical options to vary process parameters like airflow, mass flow, grinding force and classifier speed in a wide range and is .

Oil Leakage Of Vertical Roller Mill – Grinding Mill

14/10/2021 · Poor lubriion includes improper lubricant selection, improper filling amount or oil level of grease, deterioration of oil (grease) or lack of oil (grease). 1) The selection of lubricant and lubriion method are unreasonable The rolling bearing of vertical roller mill lubricant shall be selected according to the bearing operating temperature, speed index, load characteristics, lubriion ...

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER ...

Figure1. Vertical roller mill for cement grinding [13]. VRM shown in Figure1 uses hydraulically hardpressed conical shape 24 rollers against the horizontal revolving grinding table. To enhance comminution, the axes of table and rollers do not traverse in the plane of the table and approximately 150 inclination angles between

comparison of vertical roller mill to roller press

Vertical Roller Mill repair Castolin Eutectic. ble experts having worked on more than 30 different models of vertical roller mills for more than 20 cement . roller press, kiln tyre, . Vertical Roller Mill repair. Get Price And Support Online Roller Press At Cement Mill Manual. Get Price; grinding mill vs vertical roller mill

Cement grinding Vertical roller mills versus ball mills

The following presents a comparison of the two mill systems with reference to these issues. Grinding process The grinding process in ball mills and vertical roller mills differ fundamentally. In a ball mill the comminution takes place by impact and attrition. The comminution in the

The working principle of vertical roller mill | mhahpest

09/03/2015 · Working principle of vertical roller mill is driven by motor reducer rotating disc, and the hot air from the air inlet into the vertical mill, the material from the feed opening falls on the disc center, due to the centrifugal force, the material is moved from the center to the edge of the grinding disc disc, the disc by an annular groove, the grinding roller compacted by shattered, crushed ...

Advantages Of Roller Press Over Vertical Mill

Jul 04 2018 Advantages and disadvantages of vertical roller mill 1 Advantages and disadvantages of vertical roller mill Vertical roller mill vertical grinding mill is mainly suitable for ultra fine powder processing of non inflammable and non explosive brittle materials with medium and low hardness and Moh s hardness of 6.

Vertical raw mill pradeep kumar

15/05/2013 · Power taken by the millThe power taken up by the vertical roller mill is givenby the following expressionN =( I. µ .KT .DR . π.n ) / 60 K WWhere,I = rollersµ = friction factor ( for raw materials, for coal)ΚT = specific roller pressure, kN/m2(400 – 800 for raw and coal)DR = roller diameter, mW = roller ...

Best Rolling Mill For Jewelry (2020 Reviews): Our Favorite ...

1. Pepetools Ultra Series 90MM Combination Rolling Mill: Best On A Budget. Click for Price. As an Amazon Associate, we earn from qualifying purchases referred from our site. "It's our favorite budget rolling mill.". The Pepetools Ultra Series 90mm combination rolling mill is an amazing tool for such a reasonable price.

Some Questions about Vibration Vertical Roller Mills | My Blog

23/03/2015 · Some Questions about Vibration Vertical Roller Mills. There are a number of reasons for high vibrations in vertical roller mill, such as: failure of the grout or cement material under the steel beams embedded in the foundation top, which allows oil to penetrate, further degrading the concrete. The anchor bolts, which are typically large in ...

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energyefficiency. Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range. Whether grinding raw coal, clinker, cement and/or slag, we ...

Vertical Roller Mill and Its Technological Process | My Blog

24/03/2015 · Vertical roller mill called vertical mill, a cement raw materials, cement clinker, slag and cinder grinding process used, has a simple structure, low cost of manufacture and use features. Vertical roller mill includes between the body, disc and transmission means, the body and the disccentering means is provided to determine the rotation center of the.

Penna Cement Industries Limited convinced by PRESS ...

Limited, India. The vertical roller mill is to be used at the cement plant in Boyareddypalli (in the state of Andhra Pradesh), around 200 km north of Bangalore. There the vertical roller mill equipped with four rollers will grind pet coke with a throughput capacity of 52 t/h, 3% R on 90 μm.

Latest Posts

- التحليل الكلي على الحجارة كسارة

- كم يكلف بناء مصنع الاسمنت

- تكسير الحجارة المصنعة كسارة الحجر المحمولة

- سيور ناقلة في نقل الرمال

- britador eco stone para venda

- مطحنة قضيب عالية الكفاءة

- ريموند مطحنة الأسطوانة العملية

- عملية تكسير فوسفات الصخور المصرية

- مطحنة ريمون لطحن الفحم الصين

- بناة الرمل التفريغ liskeard

- بيع آلة مطحنة الكرة للمغرب

- الشركات المصنعة للمصنع الغسيل

- ماكينات رمل الكوارتز

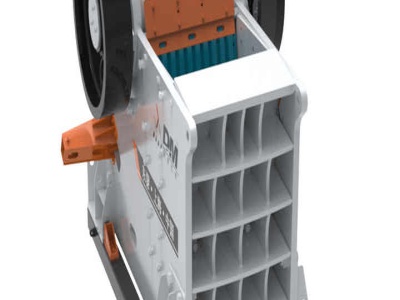

- كسارات الفك 100200 شبكة

- بدء تشغيل مطحنة الفحم الرأسي

- New Vertical Syria Grinding Mill

- Mini Gold Separator Machine

- To Calculate Crushing Value Of Aggregate

- Dominica Best Selling Primary Concrete Jaw Dominica Fo

- Alluvial Gold Processing Uzbekistan In A Boat

- Cnc Milling Searches

- Usa Pulverizer Crushing Machine Manufacturer

- Marble Grinding Mill Machine Supplier In Uae

- Advantage Of Jaw Chile Versus Impact Chile

- Best Argentina For Granite Quarries

- Kazakhstan Granite Mining Machinery Supply Kazakhstan For Sale

- Activator For Iron Ore Beneficiation

- Grinding Unit And Coal Feed

- What Is Cost Of Stone Bolivia Plant

- Marble Crushers Types In Sudan