Size Reduction How A Hammer Mill Works

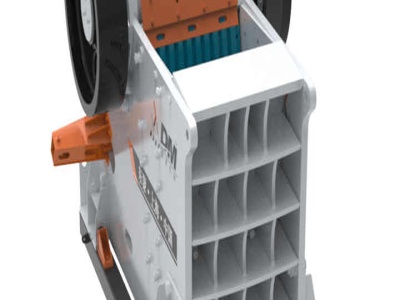

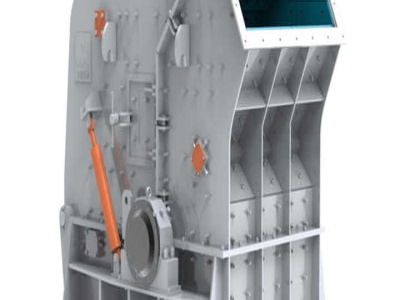

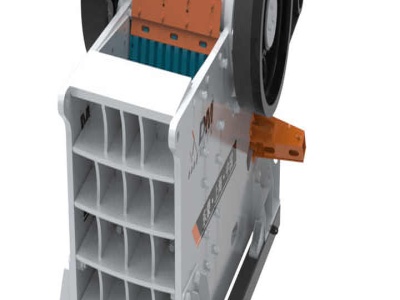

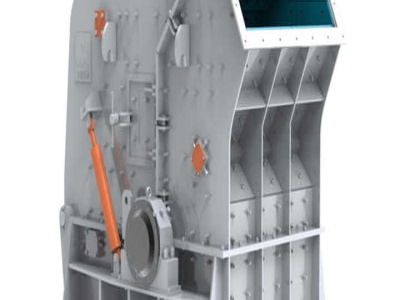

Hammer Mills for Size Reduction

Hammer Mill has various advantages: It produces specified top size without the need for a closedcircuit crushing system. Produces relatively numerous size distributions with a minimum of fines due to selfclassifiion. It has high reduction ratio and high capacity whether used for .

How Does a Hammer Mill Work?

Mar 21, 2012 · The simplest way to describe the concept of size reduction is to look at the industrial hammer mill model. Hammer mills operate on the concept that most materials will crush, shatter or pulverize upon impact. This is accomplished by a four step process: 1. Material is fed into the mill in one of many ways, including: hand fed, auger or belt ...

Unit Operation Size Reduction Hammer Mills

Unit Operation Size Reduction Hammer Mills Protable Plant » ppt on size reduction mills » cemet crushing operation particle size » pin mills verses hammer mills » used lab size hammer mills » how ro replace hammer of a ... Read more. unit operation size reduction hammer mills.

What Is A Hammer Mill Grinder How Does It Work?

A hammer mill grinder is designed to reduce bulk material into smaller pieces, either by crushing or shredding. They are an important machine in many industries, including the mining, lumber and waste management industries. However, it is most often found in grain processing facilities, as it can quickly reduce bulk grain to smaller pieces for ...

The Hammer Mill for Sizing Active Pharmaceutical ...

Nov 24, 2020 · The FitzMill TM Hammer Mill has become a popular choice within the API manufacturing industry due to its flexibility in being able to produce different target particle sizes.. The challenge of milling and sizing APIs . Commonly manufacturers of APIs deploy a variety of different mills to achieve their desired range of particle size distributions.

Wet Milling Equipment and Continuous Pureeing ...

PUREEING AND MASH GRINDING. Our pureeing appliions all typically take place in our RP Disintegrator. The RP Disintegrator is a sanitary direct drive hammer mill, designed to provide operational flexibility and mechanical reliability. Quick access to internals means easy cleaning, maintenance, and rapid changeover when milling multiple products.

SIZE REDUCTION CONTENTS INTRODUCTION CLASSIFICATION ...

CLASSIFICATION OF SIZE REDUCTION EQUIPMENT A. Crusher edge runner mill, end runner mill. B. Grinder • Impact mill. exhammer mill. • Rollingcompression. exroller mill. • Attrition mill, exattrition mill. • Tumbling mills. exball mill. C. Ultrafine grinder, fluid energy mill. D. Cutting machine, cutter mill.

Size Reduction Mechanism In Hammer Mill Is

Hammer Mills For Size Reduction Schutte Hammermill. Hammer Mills for Size Reduction Schutte mills work on the principle that most materials will crush, shatter, or pulverize upon impact. Material is fed into the mills chamber through the feed chute, typically by gravity, where it is struck by ganged hammers attached to a shaft ...

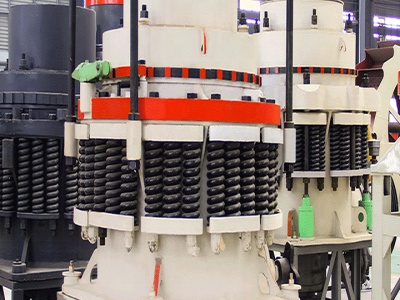

Cone Mill | Conical Milling Machine for Size Reduction

Cone milling is one of the most common methods of milling in the pharmaceutical, food, chemical and associated industries. They are typically used for size reduction and deagglomeration or delumping of powders and granules.. Generally used for reducing material to a particle size as low as 180µm (80 mesh) a cone mill produces less dust and heat than alternative forms of milling.

Hammer mills: hammermills

Hammer mills in which the rotor speed is approximately 1,800 rpm, should be using hammers which are around 25cm (~ 10 inches) long, (~ inches) wide, and ( inches) thick. For a rotor speed of about 3,600 rpm, hammers should be 15 to 20 cm (~ 68 inches long, 5 cm (~ 2 inches) wide, and mm ( inches) thick.

Mechanical Milling for Pharmaceuticals

Hammer Mill– Highthroughput hammer mills can help you achieve a variety of particle sizereduction requirements; including delumping, milling to a specific particle range, and fine grinding appliions. For pharmaceutical milling, Catalent employs hammers alongside interchangeable screen sizes, for greater control over the final particle size.

R D Equipment Company, Inc.

Come check out our large selection of Particle Size Reduction Equipment for sale. ... Jacobson Commander 2400D Hammer Mill. Details. Rietz RD1832 Disintegrator, Vertical Hammer Mill. Details. Rietz RD1832 Disintegrator, Vertical Hammer Mill. Details. Roskamp Champion Hammermill 24x48.

What are the Benefits of Pneumatic ...

Nov 02, 2012 · Size Reduction 101. Hammer mills of all shapes and sizes process material with the same basic pulverizing action. Rectangular steel hammers are attached to a shaft inside of a steel grinding chamber. As the shaft spins, the hammers flail out bringing them into contact with the material being processed. A combination of hammer blows, particle on ...

Size reduction equipment for hemp products

KannaMill ® size reduction equipment has been designed in partnership with high production hemp processors. At the heart of every KannaMill ®, is our long history of manufacturing rugged, durable equipment. Our heavyduty designs meet the demand for low maintenance, and are scalable for various levels of highthroughput production.

Jet mill working principle

How dose a jet mill work? This article aims to describe the working principle of a jet mill. A jet mill, also called fluid energy mill, is used for solid material micronization. Micronization is a term used to describe size reduction where the resulting particlesize distribution is less than 10 microns.

Size reduction

Jet mills are achieving a size reduction by accelerating the product to be milled and throwing it either against a static target, either against another flux of accelerated particles To achieve this purpose, speed of up to 250 m/s must be reached in order to give enough energy to the particles to break them at the impact.

Hammer Mills

Reduce a broad range of materials into particle sizes from coarse to fine — efficiently, at high rates. Munson's HammerHead™ Hammer Mills reduce an exceptionally wide range of friable, nonfriable and fibrous materials into particle sizes from coarse pieces down to 200 mesh, determined by friability of the material.

AN OVERVIEW ON SIZE REDUCTION

Sep 12, 2020 · The ball mill works on the principle of impact between fastmoving balls and powder material, both of which are enclosed in a hollow cylinder. ... factor affecting size reduction, fluid energy mill, hammer mill, how to size reduction, instruments used in size reduction, jet mill, kick's theory, machine used in size reduction, ...

Hammer Mills and Material Size Reduction Equipment

Our hammer mills are commonly used for many different particle reduction appliions, including those that require high capacities, extreme power efficiency, and uniform particle size. With a Prater hammer mill, you can increase the mill's throughput capacity without having to increase its power requirements.

Hammer mills

Multimill hammer mill series. The Multimill series consists of finegrinding hammer mills. The Multimill is designed with small hammertoscreen clearance that secures minimum particle size. Key features: Optimum particle reduction; Small screen area; Low temperature operation for protection of nutritional value of feed ingredients

Air Swept Classifier Mill System

Grinding Classifying. Grinding and Classifying are essential size reduction processes. The CMS Air Classifier Mill Grinding Zone configuration positions Impact Hammers mounted at the periphery of the Rotor Plate (below the Classifier Wheel), a reversible Multiple Deflector Liner enclosing the Rotor Plate, Hammers and a Deflector Assembly (shroud/baffle style) loed above the Impact Rotor.

Make Your Own Wood Pellets with GEMCO Small Pellet Mill ...

May 19, 2015 · The size of the raw materials before feeding into the pellet mill shouldn't be larger than 1 inch (), so you should use a hammer mill to reduce the size and make it as small as possible. The hammer mill can run at a high speed ranging from 3000RPM to over 8000RPM.

DESIGN CONSTRUCTION OF HAMMER MILL MACHINE | .

Hammermill. Ballmill. Nut crackers. Attrition mills. Micromills etc. The use of any of these equipments depends on productivity, particle size requirement and nature of materials to be handled. These machines could as well be employed in particle size reduction in the food processing industry. Hammer mills, micromills especially serve this ...

The mechanism of size reduction by a hammer mill is by ...

MCQs: The mechanism of size reduction by a hammer mill is by impact and attrition between the? (A) Grinding element the housing (B) Feed particles ... Particle size range in which dust cher (gravity settling chamber) works most effectively and efficiently is .

Latest Posts

- العمودية مطاحن الأسطوانة معدات التعدين

- الكوارتز كسارة الحجر سعر المصنع للبيع

- من جهة ثانية تكسير وغربلة النبات تكاليف

- مصنعي آلات الاسمنت في أوروبا

- الشركة المصنعة لآلة طحن مسحوق المنغنيز

- سحق نباتات الفرز

- الحصى الأبيض الموردين في دبي الإمارات العربية المتحدة

- آلات طحن مستعملة للبيع في ولاية تكساس

- مطاحن المنشار مستعملة للبيع في أوكالا فلوريدا

- معدات مطحنة الدحرجة العمودية

- مثال تحليل كدح صناعة التعدين

- سعر كسارة الفك الحجر الحجم

- مواصفات وإنتاج محطة تكسير الصخور البازلتية

- مصانع كسارة في العراق

- معدات الرسوم المتحركة الرملية

- Zenith Hp700 Adjustment Ring For Sale

- Crushing Hammer Mills In Malaysia

- Y Series Mobile Combined Crushing Plant

- Mhada Application No

- Vsi Malaysia Feldspar Malaysia

- Factor Affecting Grinding Mill

- Used Ball Mill For Sale

- 200tph Mobile Sudan

- Portable Jaw Crushing Plants

- Gold Mining Brazil For Sale In Dubaix4

- Dimensions Of Gears For Ball Mills

- Saudi Arabia Plant Process

- Trituradoras Pdf

- Sodium Sulphate Ballestra

- Raymond Grinder Mill