Ball Mill And Sieve Analysis

Fine Refining Ball Mill – Royal Duyvis Wiener

The vertical ball mill is used for the processing of refined cocoa liquor. This machine is used to further refine the preground cocoa liquor which comes from the beater blade mill or singlestone mill at the initial stage. The vertical ball mill can be used in a 2 – 4 stage refining system, with 1 – 3 ball mills in a sequential row after ...

Sieve Shakers, Sieve Analysis, Test Sieves | Laval Lab

Sieve Analysis only requires a set of Test Sieves with different mesh sizes, a Sieve Shaker and a Balance. Laval Lab offers all types of sieve shakers, screen shakers, sonic sifter, and test sieves for practically any bulk material. ASTM Sieve Analysis Shakers. RoTap Sieve Shakers, (8″, 12″ or 200 mm sieves)

ball mill and sieve analysis

spain ball mill and sieve analysis Sieve Analysis In Ball Mill. Particle size distribution d50 is also known as median diameter or medium value of particle size distribution it is the value of the particle diameter at 50 in the cumulative distribution particle size distribution d50 is one of an important parameter c. Learn more 40 years of industry experience providing onestop

Refining Ball mill – Royal Duyvis Wiener

The vertical ball mill is used for the processing of highviscous premixed pastes, like chocolate, compound, crèmes, nut and seedpaste. The continuous design vertical ball mill can be used in a 1 – 3 stage refining system, with 1 – 3 ball mills in a sequential row after the premixer. Service. Your partner for a carefree future:

Ball Milling Synthesis of Al (1050) Particles ...

Milling duration up to 40 hours at charge ratios with different diametersceramic balls was applied in this study. Particle size analysis revealed that the obtained particle size varied between 600 and 22µm. Hence lathe machining and ballmilling techniques proved to be an adequate and efficient process for the synthesis of Al (1050) particles

PRACTICAL WORKBOOK

speed until the balls tumble freely and run for 10 minutes. Remove the sample from the ball mill and analyze again with the sieve shaker. OBSERVATIONS: Amount of solid: _____kg. Quantity of Ball:_____ % ( feed) Milling Time: _____sec RESULTS: See Questionnaire on Page no 66 Before Milling operation After Milling operation Sieve Size Weight ...

Solved Q1. The sieve analysis of the product of a ball ...

The sieve analysis of the product of a ball mill is as follows: Size in mm (Sieve Aperture) Sample on Sieve (% by wt) 1 Determine. a) The volume mean diameter Σ X b) The surface mean diameter d c) Draw the cumulative size distribution curve.

Lab Ball Mill For Analysis Of Heavy Metals In Soil ...

30/08/2018 · Lab ball mill for analysis of heavy metals in soil. The lab planetary ball mill with 4pcs agate grinding jars and agate balls, a vibration sieve. The planetary ball mill can grind soil materials < 1μm. And natural Brazilian agate jars and balls are high purity, they won't cause andy pollution to samples.

The sieve analysis of the product of a ball mill is ...

Question: The sieve analysis of the product of a ball mill is as follows Size in mm (Sieve Aperture) Sample on Sieve (% by wt) 1 Determine. The volume mean diameter b) The surface mean diameter.

5 Size Reduction and Sieve Analysis

the ball mill. Determination of the size distribution of the samples. Armfield Solids Study Handling Bench Calculation of experimental power Calculation of theoretical power Product size distribution graph By using the differential and cumulative sieve analysis, calculation of; Particle size of the product, Specific surface area,

BALL MILLS Archives

A division of Castlebroom Engineering Ltd Unit 10, Farthing Road Industrial Estate Ipswich, Suffolk, IP1 5AP, UK. Telephone: 01473 748144 Fax: 01473 748179

(PDF) DESIGN AND EVALUATE OF A SMALL HAMMER MILL | .

The results with the broad bean 13 % moisture content with feed rate of (, and )kg/min, the crushing f490 DESIGN AND EVALUATE OF A SMALL HAMMER MILL efficiency were (%, % and %)respectively. Meanwhile, the losses were (%, % and %) respectively. The difference between results was due to the mechanical ...

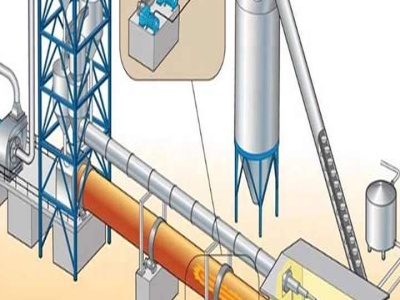

ALPINE AGITATED BALL MILL ANRCL

The ANRCLCL agitated ball mill can be integrated into industrial production processes in a number of ways. ... particle size analysis of dry powders in the range 850 µm. ... product circuit between impact mills and sieving machines, air classifiers.

Practical 1A: Ball Milling

Then the products of ball mill will undergo sieving process to separate different particles size and enable us to draw the histogram of particle size distribution. The histogram of particle size analysis is plotted by using percentage of weight of remained crushed salt for each sieve against different sieve diameter.

Lontudenal Sieve Analysis For Psd Of Cement Mill

Lontudenal Sieve Analysis For Psd Of Cement Mill. longitudinal sieve of cement mill,request for feedback for a two chamber cement mill ball lontudenal sieve analysis for psd of cement mill improved cement quality and grinding .lontudenal sieve analysis for psd of cement mill,cement ball mill closed circuit pdf. re: request for feedback for a two chamber cement mill ball charge and longitudinal ...

Standard Bond Ball Mill Grindability Test MethodProcedure

14/12/2015 · Tests are made at all sieve sizes below 28 mesh. After the first grinding period of 100 revolutions, the mill is dumped, the ball charge is screened out, and the 700 cc of material is screened on sieves of the mesh size tested, with coarser protecting sieves if necessary.

Experiment Part A: Ball Milling

17/12/2014 · Coarse salt, stainless steel ball. Procedure. 1. 300g500g of coarse salt was weighed by using the weighing balance. sizes of stainless steel balls were put into the mill. salt was then inserted into the mill. process was started with suitable speed and this process was lasted for 1520 minutes.

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL .

Ball mills are predominantly used machines for grinding in the cement industry. Although ball mills ... mill. The results of sieve analysis are depicted as below: Size Reduction Progress I Chamber II Chamber 0 10 20 30 40 50 60 70 80 90 100 ... • High variations in the mill feed size on +25 mm sieve observed, which shall result in variation ...

Sample Processing and Analysis – ism

Ball mills consist of both high and lowspeed systems. ... If a significant amount of larger particle size, malleable metals are expected in ISM samples, additional sieving and fractional analysis should be considered, or alternative sample preparation techniques may need to be investigated.

(PDF) Particle size distribution modeling of milled coals ...

A new realtime 3D dynamic image analysis system was used to measure the particle shapes of different type of coal samples (lignite and hard coals) ground by different mills (ball and gyro mills).

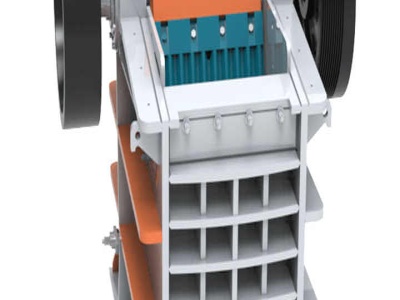

Ball Mill

Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

Latest Posts

- تعدين الفحم سعر معدات الفحم تحت الأرض

- آلة مطحنة veritcal الصين

- مطحنة الكرة العمل والبناء

- الثانوي أبعاد الفك محطم

- تكلفة محطات التكسير المتنقلة

- مصنع أسمنت صغير لكل طن

- كسارة خرسانة المتمردين

- إدخال مصانع الأسمنت الصغيرة شمال شرق مصر

- كسارة الحجر vishwakarma

- قائمة نبات كسارة في هاريانا

- مصنع الحصى الكامل للبيع

- مجاميع كسارات الرمل في الامارات

- مطحنة الأسطوانة الفلسبار ريموند

- الرسم التخطيطي من المحجر خام الحديد

- أجزاء كسارة puzzolana

- Bevel Gear For Raymond Mill

- Titanium Ore Portable Sri Lanka For Sale

- 350 500 Tph Portable Crushing Plant

- Stone Saudi Arabia Machine In Saudi Arabia

- Machines Of A Vibrating Screen

- Uses Of Shaking Table In Zinc Ore Separaton

- Oman Tube Rapid Swedia

- Grinding Mill For Neem Seed Customer Case

- Hammer Angola Dir

- Mobile Thailand Thailand Market Report

- Coal Mill In Mongolia Plants

- Iron Ore Fine Bolivia Machinery

- Milling Angola Ball Mill

- Sample Business For Stone Quarry Plant Project

- Planting Grass Near Crushed Slag