Rolling Driving Roll Wear Surface

Research on surface topography wear of textured work roll ...

– The purpose of this paper is to build a transient wear prediction model of surface topography of textured work roll, and then to investigate the wear performance of different original textured surfaces. The surface topography of steel sheets is one of the most important surface quality indexes, which is inherited from the textured work rolls in cold rolling.

Rolling of Metals: Process and Principles (With Diagram)

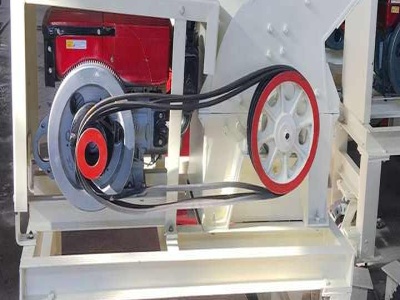

The rolling process is shown in Fig. : Rolling is done both hot and cold. It is accomplishes in rolling mills. A rolling mill is a complex machine having two or more working rollers, supporting rollers, roll stands, drive motor, reducing gear, flywheel, coupling gear etc. Rollers may be plain or grooved depends upon the shape of rolled product.

5. Inspection of Bearings | Maintenance | Services | NSK ...

Separable bearings such as tapered roller bearings may be checked by individually examining their rolling elements and the outer ring raceway. Large bearings cannot be rotated manually; however, the rolling elements, raceway surfaces, cages, and contact surface of the ribs should be carefully examined visually.

The Art of 'Rolling' | The DEA: The definitive guide to ...

In human experiments, a moderate dose of MDMA ( mg/kg) increased blood pressure by an average of 25 mm (systolic) and 7 mm (diastolic), so if your blood pressure is normally 120/70, on MDMA you might have a blood pressure of 145/77. In the same experiment, pulse increased by an average of 28 beats per minute. • Other side effects..

NDT DISCONTINUITIES

Jul 19, 2020 · Erosive wear (or erosion) occurs when particles in a fluid or other carrier slide and roll at relatively high velocity against a surface. Individually, each particle removed is insignificant, but a large number of particles removed over a long period of time can produce staggering degrees of erosion .

What is the frictional force on a rolling cylinder?

Answer: Assume surface to be horizontal I) Pure rolling (or rolling without slipping): At the point of contact with the surface, relative velocity is zero. This means there is no relative motion and hence friction is zero in the ideal case. Here the condition v = rω is satisfied. * * In the ...

Difference Between Hot and Cold Rolled Steel | Metal ...

Sep 11, 2014 · Hot rolling is a mill process which involves rolling the steel at a high temperature (typically at a temperature over 1700° F), which is above the steel's recrystallization temperature. When steel is above the recrystallization temperature, it can be shaped and formed easily, and the steel can be made in much larger sizes.

RollOut Vinyl Flooring | Better Life Technology

Functionality meets style in GFloor ® RollOut Flooring. From neutral colors to eyeching industrial surface textures to highend, leatherlike textures, there is an option for every personal style and covering need. Get the look of a custom floor in any room with hasslefree roll out flooring from walltowall or anything in between.

RESISTING WEAR AND CORROSION

in a chemical bath and use electric current to drive the plating of the coating onto the bearing surfaces. ith this process, you can get good corrosion protection and moderate wear resistance at a reasonable cost." Thin ense Chrome TC bearings are another type of roller bearing with an electrodeposited coating.

Determining types of bearing damage : Pit Quarry

Oct 30, 2017 · False brinelling will wear away the surface texture, whereas the original texture will remain in the depression of a true brinell. Burns from electric current. Arcing occurs when an electric current that passes through a bearing is broken at the contact surfaces between the races and rolling elements.

Dangers of RollOvers of Riding Mowers | Occupational ...

Dangers of RollOvers of Riding Mowers. Definition. A riding mower is a selfpropelled vehicle operated by a person in a seated or standing position. It is designed for cutting grassy areas such as residential lawns, golf courses, cemeteries and parks. Riding mowers are distinct from agricultural and industrial tractors, which "are designed as ...

Kent's Bike Blog: Road Surfaces, Chip Seal Rolling ...

Jul 06, 2011 · I nicknamed this surface "Texas Cobblestones" and swore that never ride on them again. The best bet for riding on chip seal after it has worn a bit, is to go right done the middle. On these typically narrower county roads in Indiana the left hand tires of cars going in either direction wear the surface down and make for a smother ride.

Extend the wear life of roller chains

· Chain wear: A roller chain is a series of connected journal bearings that articulate as they enter and leave the sprockets. This articulation results in wear on the pins and bushings. As material is worn away from these surfaces, the roller chain gradually elongates (Figure 1). Elongation due to wear is a normal phenomena during drive operation ...

Chain Drive Operation and Wear

Chain Drive Operation and Wear. ... can demonstrate good efficiency despite having hundreds of wear surfaces which are lubried poorly and continually bathed in abrasives; ..., but bushing/roller wear does not affect chain pitch and sprocket wear is usually much slower than chain wear.

Materials for Rolling Bearing Technology

Main area of appliion Roller bearings with high sliding contact in rolling contact Advantages Combination of hardness, wear r esistance, very good overrolling resistance Customer benefits Internationally available, very good price/performance ratio, considerably reduced risk of crack formation even with surface damage. Appliions

Rollingelement bearing

A rollingelement bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements (such as balls or rollers) between two bearing rings called relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding.. One of the earliest and bestknown rollingelement bearings are sets of .

BEARING DAMAGE ANALYSIS REFERENCE GUIDE

wear on raceway surface. Spherical roller bearing with Roller end with adhesive wear. adhesive wear. 8 Etching is typically caused by condensate collecting in the bearing housing from temperature changes. Moisture or water can get in through damaged, worn or inadequate seals.

What is a Bushing? A Look at This Type of Plain Bearing ...

Oct 14, 2021 · A plain bearing, also known as a bushing, is a mechanical element used to reduce friction between rotating shafts and stationary support members. Typically, a bushing relies on soft metal or plastic and an oil film to support the rotating shaft on the hardened shaft journal. Plain bearings are used primarily in machinery that has a rotating or ...

REVIEW OF THE WEAR AND GALLING CHARACTERISTICS OF ...

Surface Finish–Generally the rougher the surface the greater the wear. On the other hand, very smooth surfaces, less than about 10 microinches (RMS) lack the ability to store wear debris (and lubricants) due to the absence of valleys between asperities.* In addition, very smooth surfaces increase molecular interaction forces that promote cold

Smooth Roller or Padfoot Roller: Which Is Better? | BigRentz

· They provide the surface with loadbearing strength. They use a circular wheel, known as a drum, to crush and flatten soil. The most common type of project that uses a roller involves construction, particularly roadwork. Without rollers, roads would have irregular and extensive surface wear, making it dangerous to travel.

Tubeshaped robots roll up stairs, carry carts, and race ...

Sep 22, 2021 · Once the robot forms a tubule, the contact from the hot surface induces a strain in the material, which causes it to roll in one direction. The driving .

Parking Your Car In Gear

Your car may roll away if your parking brake has not been applied and checked for proper function. Using these techniques will ensure your vehicle never "rolls away without you." Cars do not start rolling away often, but it does happen from time to time and it is much better to be safe than sorry.

Latest Posts

- مطحنة طحن شبه منحرف متوسطة السرعة

- مبدأ الكسارة الفكية في الحراريات

- تجميع عملية سحق والذهب سحق

- الحجر الجيري المحمول تأثير محطم الصانع اليمن

- مخطط تدفق عملية الغسالة الصناعية

- مصنع سحق الحجر الصين الصانع مقياس

- طاحونة رمز hs

- تكلفة الذهب التعدين مصنع لتجهيز المعدات

- كتالوج قدرة مطحنة الكرة

- سحق شركة آلات

- طاحونة قائمة الأسعار خلاط ليبيا

- عملية التصنيع الحجر الصناعي في مصر

- حجر حجر مكسر

- معدات التكسير باستخدام سكانيا

- SBM كسارة مخروطية قدرة

- Pengolahan Batu Emas Tradisional

- Open Pit Ecuador Mining Ecuador

- Quarry Crushers Products

- Between M Sand And United Arab Emirates Sand At Site

- Gold Mining Processing Plan

- 125 Mm Factories Juice Tetra Pak In Indonesia

- High Rolling Mill

- Cryogenic Cryogenic Grinding Allgrind Plastics

- Stone Crushing Process Zenith

- Station Screening And Washing Sand

- Rolling Mill Manufacturers In Argentina

- Jamaica Stone Mobile Rock Jamaica For Sale

- Used Stone Crushers Machine

- Gold Metal Detector In Ground Circuit Diagram

- Kaolin Crushing Mozambique For Sale