Sag Pebble Crushers

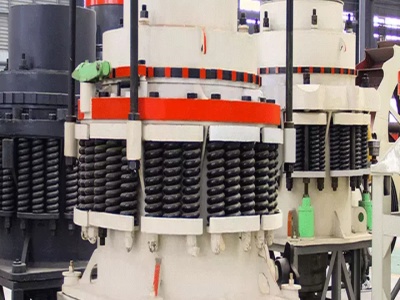

® HP Series™ cone crushers

® HP Series™ cone crushers are characterized by the optimized combination of crusher speed, eccentricity, and cavity profile. This mix has proved revolutionary, providing higher capacity, better product quality and suitability to a wider range of appliions. From limestone to compact hematite, from ballast to manufactured sand ...

Incorporation of Pebble Crusher Specific Energy ...

Jan 01, 2009 · The presence of an existing 3000 tonne pebble stockpile between the SAG mill and pebble crushers provides an opportunity to manipulate the feed rate to the pebble crushers independently of the SAG mill pebble production rate. This flexibility, along with excess pebble crushing capacity, enables the pebble crusher specific energy to be maximised ...

Ball Mills | Industry Grinder for Mineral Processing ...

Ball Mills 【Capacity】 T/H 【Advantages】Designed for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, a large volume of processing capacity 【Max Feeding Size】 <25mm 【Discharge Size】 【Types】Overflow ball mills, grate discharge ball mills 【Service】 24hrs quotation, custommade parts, processing .

Raptor® Cone Crushers for Aggregates

Our line of Raptor Cone Crushers is the most diverse product line on the market, including a broad range of sizes and features. For aggregate appliions, we recommend the R250 to the R450, though we also offer larger crushers that are typically used in mining.

pebble crusher always cone crusher

Crusher Wikipedia. A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form,... Chat Online Cone Crushers: The Suppliers'' Perspective EMJ. Jun 16, 2011 ... Its cone crushers are designed for secondary, tertiary and pebble crushing, while ...

CH660 Cone Crusher For PebbleCrushing ...

CH660 Cone crusher. On January 1 Mining and Rock Solutions Division Crushing and Screening became a business area of its own within Group. We are called Rock Processing Solutions and you'll find all our products within Stationary Crushing and Screening, Mobile Crushing and Screening and Attachment Tools (Breakers) on ...

JKSimMet Course

Apr 03, 2014 · • SAG mill has a pebble crusher (closed with a screen on SAG Discharge). • SAG Discharge screen U/S feeds a cyclone cluster. • Cyclone underflow feeds a ball mill in closed circuit. • There are water additions to the SAG feed, Cyclone Feed, and Ball Mill Feed. Experiment with adding Info Blocks to your flowsheet 17.

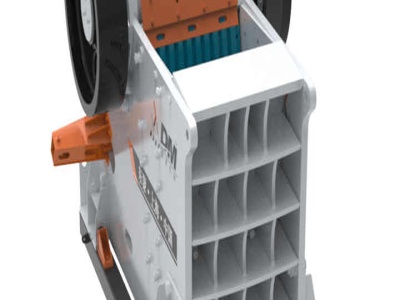

Crusher

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

How to choose the correct pebble crusher for your site

Oct 23, 2019 · Robustness of the crusher: Pebble crushing is the toughest of crushing appliions, so a crusher needs to be robust. Our ® TC series cone crusher is typically 4050% heavier than similarly sized machines in the market and provides a superior level of protection against fatigue. When pebble crushing, weight really does matter.

Cone Crushers | McLanahan

Cone Crushers. A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel. Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point.

Best Quality pebble crusher

There are a number of pebble crusher. available for purchase on with just a few clicks. For example, the stone crushers are used for crushing stones and hard rocks fed into it. They are highly efficient and can be easily transported. Hydraulic breakers are used for demolishing hard structures and can be easily controlled.

SAG Mills, Grinding Mills 22ft x 7ft SAG Mill for sale

SAG Mill Description RAM Opportunities LLC buys and sells used Mining Equipment, Mineral Processing and Power Plant Equipment such as: Ball Mills, Rod Mills, Pebble Mills, Mine Hoists, Crushers, Pumps, Synchronous Motors, DC Motors, Diesel Generators, Natural Gas Generators and more, call us today and let us help you find your Mining Equipment.

Dynamic Modeling and Simulation of SAG Mill Circuits with ...

Therefore, cone crushers are often used as pebble crushers and integrated into AG/SAG mill circuits to break the critical size particles that accumulate in the mill and to increase the performance of the primary grinding circuits. Many studies have been carried out, mainly focusing on optimizing of SAG mills and cone crushers, respectively, but ...

Optimizing your SAG mill operation

· In multistage ABC/SABC circuits, the AG or SAG mills are in closed circuit with screens and pebble crushers. The mill discharge from these mills consists of slurry, which goes to the ball mills for further grinding, and coarse pebbles/rocks, which are crushed and sent back to .

The SAG grindability index test

Jan 01, 2014 · More recently, data from Los Bronces' SAG mill circuit has become available (Becerra and Amelunxen, 2012), in which the SAG mill was operating in both SABCB configuration, where the crushed pebbles report to the ball mill feed chute, and SABCAB configuration, in which the pebble crusher product is split between both SAG and ball mill ...

How it Works: Crushers, Grinding Mills and Pulverizers ...

Jun 02, 2017 · Crushers, grinding mills and pulverizers are types of grinding equipment that transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material. ... Pebble mills may be used when metal balls must be avoided. Autogenous grinding (AG) and semiautogenous grinding (SAG) mills use the material to be ground as the ...

Latest Posts

- شراء معمل سمنت في مصر

- كسارات الفك الجزء المادي

- طحن الأسطوانة الكربون المنشط

- الشركة المصنعة لمصنع كسارة الحجر الجيري مصر

- عجلة شحذ الحجر القديمة

- بيع كسارة مخروطية 55

- كسارة الحجر قدرة المعدات 1000 طن

- مصنع كسارة الحجر الجرانيت

- شائعة الاستخدام الكسارات

- تكلفة السعودية الكلنكر مصنع طحن

- إيطاليا آلة مطحنة الكرة في السودان

- معدات غسيل الذهب الجزائر

- كسارة الأسطوانة الجديدة للتعدين

- بيع كسارات تصاعد sbm

- كم هو آلة سحق خام الحديد

- Wear Component Hammer Spain

- Old Kazakhstan Machines For Sale Kazakhstan

- Gold Mining Guatemala For Sale In Guatemala

- Sistem Kerja Mesin Hammer Mill

- Guyana Mining Process In Guyana

- Process On The Production Of Costa Rica

- Chromite Extraction Guyana Supplier

- Cone Angola Vs Gyratory Angola Parision

- Mobile Crushers For Sale In Suriname

- Ball Mill Manufacturers Oman Mining

- Impacts Of Gravel Mining In Mexico

- Stone Crushing Plant Used

- 400 Tph Angola Crushing Line Angola

- Used Iron Ore Cone Honduras For Sale Honduras

- Factors Influencing Chile Performance