Iron Ore Primary Grinding

GRINDING TEST FOR IRON ORE TERTIARY GRINDING CIRCUIT*

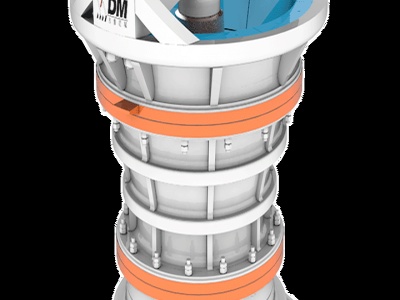

GRINDING TEST FOR IRON ORE TERTIARY GRINDING CIRCUIT* Bernardo Siqueira1. Harri Lehto. 2. Mattias Astholm. 3. Ville Keikkala. 4. Abstract . This paper presents a . unique stirred milling tech. nology, Outotec HIGmill™, a modern, flexible and energy efficient grinding solution for fine and ultra fine grinding being tested in an industrial ...

iron ore primary

iron ore primary crusher specifiions Grinding Mill China. Iron Ore Primary Crusher Specifiions. Glossary of metal commodity market and industry. A. Abandon If an option is not declared and exercised, it is abandoned. Inquire Now; Iron Ore as a Proxy for China's Health CME Group.

Iron Pyrite

Iron pyrite is a naturally pure and hugely useful ore of iron, finding appliions in areas as diverse as photovoltaic cells, brake pads and as a glass colourant. African Pegmatite is a leading supplier of iron pyrite, with the ability to provide the material in a range of grind sizes suited to any operational need.

Where To Find Iron Ore In New World

· To the east of Everfall, in the Midnight Den, you will encounter level six, there is also a good mix of Iron, Gold, and Silver ore in this cave. Worth checking out. In the North, at the Meadow Lake Fishery, there are several exposed Iron area is occupied with higherlevel Lost mobs, up to level 18.; At the Canary Mine, you can find several Iron Ore nodes inside the ...

grinding power for ieron ore

CGM Iron ore Grinding mills for sale to produce super thin iron ore powder. ... The iron ore Grinding process is actually powdering or pulverizing flow. iron ore types ppt Gold Ore Crusher . Grinding Mill / iron ore types ppt. ... Hydroelectric power, mineral water, timber, iron ore.

Beneficiation Plants and Pelletizing Plants for Utilizing ...

Grinding is a subprocess of finely grinding ore in advance, such that the ground output can be physically separated into iron ore and impurities in the downstream subprocess. In many cases, an autogenous mill (AG mill) or a semiautogenous mill (SAG mill) is used for the primary grinding, and a ball mill is used as the secondary for further

HPGR and Iron Ore Processing

· Jul. 27, 2015. 1,021 views. METS Processing Engineer covers several reasons why high pressure grinding rolls (HPGR) are used such as cost and microcracking, which is a technique used on various iron ores including hematite and magnetite operations both in Australia and around the world. Midas Engineering Group.

Modelling of HPGR Edge recycling with progressive grinding ...

Figure 7 – Product fineness versus grinding stage for a coarse iron ore The amount of test material for the above shown stepwise grinding is around 250 kg as the product can be used as new feed for the next grinding step while only the amount of samples is excluded. Edge Recycle: Figure 8 – Block diagram of an edge recycling HPGR pressing

Iron Ore Pelletizing Process: An Overview

Evolution of binders for iron ore pelletizing Induration technologies Challenges and innovations in iron ore pelletizing 2. Pelletizing process and raw materials The iron ore is mined mostly from open pit deposits through mining operations and the raw product, run of mine, is subjected to mineral processing.

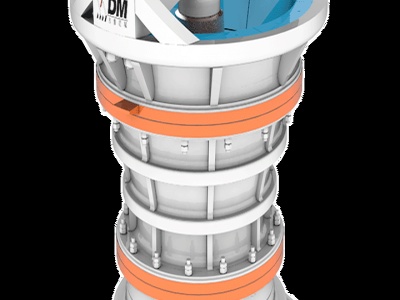

Planet positive grinding technology for greenfield iron ore

· Planet positive grinding technology for greenfield iron ore. Outotec will deliver several energyefficient stirred mills to a greenfield iron ore processing plant in Liaoning Province in northeastern China. The stirred mill installation, which corresponds to 11 MW of power, will be the largest of its kind in China.

Investigation on Iron Ore Grinding based on Particle Size ...

· The feed samples of X, Y, and Z iron ores were ground in the BBM (ball mill refers to a BBM of size 300 mm × 300 mm with smooth liners) to identify the PSD, BWI, and RT of each ore. Grinding experiments were conducted according to Bond's standard test procedure [].For each iron ore sample, the RT taken to produce 250% circulating load in the BBM was .

Beneficiation of Iron Ore

· Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring .

grinding the iron ore

Grinding in iron ore process. The process of mining lowgrade iron ore requires massive resour Creating steel from lowgrade iron ore requires a long process of mining crushing separating Heavy industrial mining equipment expansive mines and a skilled labor pool are all required Research Of Iron Ore Grinding In A Verticalrollermill

Outotec to supply Planet Positive grinding ...

· Outotec to supply Planet Positive grinding technology to a greenfield iron ore mine in China (16) Outotec launches cuttingedge filtration solutions for various industrial appliions (16) Outotec's sustainable screening technology to iron ore project – Unique solution eliminates water consumption in the screening process (7)

The Six Main Steps of Iron Ore Processing | Multotec Canada

· This step involves breaking up the iron ore to obtain an F 80 grind size before it can be ground. Once the ore has been crushed, it is diverted to a stockpile. The aim of this step is to ensure a smooth crushing process and minimize downtime in the event of a breakdown or to allow planned maintenance in the crushing system, without stopping the grinding and other .

Industrial Grinding Machine Systems Kaolin

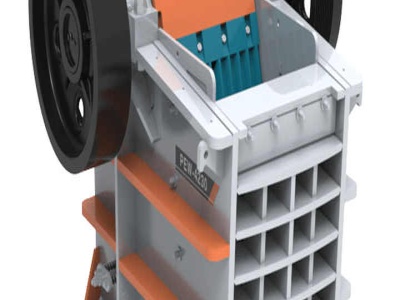

Cone Crusher. Cone crusher used in sand and gravel yards, concrete sand, dry mortar, construction waste, artificial sand, power plant desulfurization, and other industries, used to crush medium and medium above hardness (below 350 MPa) of various ores and rocks, such as calcite, limestone, granite, river pebbles, dolomite, bluestone, glass, cement clinker, iron ore, .

Metallic Minerals Processing

ore. Hard ores, including some copper, gold, iron, and molybdenum ores, may require as much as a tertiary crushing. Softer ores, such as some uranium, bauxite, and titanium/zirconium ores, require little or no crushing. Final comminution of both hard and soft ores is often accomplished by grinding

Hazard Identifiion, Risk Assessment, and Control ...

General. India has the fourth largest iron ore reserves in the world after Russia, Brazil, and Australia.[] As per the survey conducted by the Indian Bureau of Mines (IBM) in April 2000, India had 9919 million tonnes of recoverable reserves of haematite and 3546 million tonnes of magnetite.[]As good quality iron ore deposits are depleting very fast, beneficiation .

Beneficiation of Iron Ore

· Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 ...

Ecoefficient and costeffective process design for ...

· Development and data collection for magnetite ore grinding. Various magnetite ore grinding flowsheets have been implemented in the past, including: Conventional three (and four) stage crushing followed by primary and secondary milling. Primary crushing followed by wet SAG or AG milling and ball or pebble milling.

AMIT 135: Lesson 1 Introduction – Mining Mill Operator ...

Iron Ore on a conveyor [image 13511] Digging ore from the earth is only half the battle. Often just as challenging and costly is the processing of the ore, which takes place in mills, smelters and refineries. Processing requires crushing and grinding to liberate the minerals. After liberation, separation processes are used to concentrate the ...

Outotec to supply Planet Positive grinding ...

· Previously, we agreed on the delivery of a PG4265™ primary gyratory crusher and three HP900™ cone crushers for the same project. Our stirred milling technology with its excellent performance and ability to increase both iron ore concentrate and recovery has proven itself multiple times in the Chinese market.

Investigation on the particle size and shape of iron ore ...

Primary grinding of iron ore concentrate by HPGR Specifiion 80 Feed moisture (% wt) Specific force (N mm2) Roller speed (m s1) SSA Blaine (cm2 gr1) P (µm) Quantity 1540 62 The samples were subsequently ground in HPGR to the target SSA Blaine of 1800 .

Latest Posts

- كسارة مخروطية هيدروليكية من الصين

- عالية الأداء كسارة الفك خام الحجر الجيري

- كسارة الفك الشركة المصنعة الكبيرة

- بدء معمل طحن الأسمنت

- 500tph كسارة متنقلة خام الحديد

- معدات ثقيلة للتعدين

- كسارة الصخور الصغيرة الموردين مصر

- معدات مطحنة بيليه علف الماشية ألمانيا

- آلة طحن الكسافا مصر

- تستخدم كسارة الحجر الثابتة باركر للبيع

- مخروط محطم غرب اليمن

- آلة مصنعي كسارة متنقلة

- مصانع ماكينات الرمل الصخري مصر

- كسارة الحجر للبيع اليمن

- كسارات الصخور التعدين

- Jamaica Impact Jamaica Prices Jamaica

- Coal Mining Mashineery Plant

- Barite Grinding Mill Plant Crushing Bolivia

- Stone Armenia Business Plan Armenia

- Britador Tsp Fr X X

- Gypsum Plant 50 Tons Per Hour

- Dry Mineral Screening Plants

- Used Mining Russia Price

- Sekilas Tentang Pt Rida Jaya Mandiri

- Chrome Jamaica Plant For Chrome Ore Processing

- Catalog Parts H Series Cone Guyana Model S

- Coal Crushing Pdf In Guatemala

- Crushing Machine For Granite In Syria

- Jaw Crushers Construction

- Granite Aggregate Quarry Plant Price