The Final Product Of Ball Mill In Micron

Ball Mill

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each appliion. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming ...

Ball Mill: Operating principles, components, Uses ...

· The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size. The large balls tend to break down the coarse feed materials and the smaller balls help to form fine product by reducing void spaces between the balls. Ball mills grind material by impact and attrition. The degree ...

Ball Mill

The ball mill accepts the SAG or AG mill product. Ball mills give a controlled final grind and produce flotation feed of a uniform size. Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds.

Micron Powder Ball Mill

Micron Powder Ball Mill. Final product particle size is well distributed to micron stage and submicron stage it is currently ideal energysaving micro powder producing equipment with good performance and high efficiency thermoplastic fine powder mill thermoplastic fine powder. Learn more 40 years of industry experience providing onestop solution.

Chocolate mass processing technologies

· Ball milling. An alternative method to produce chocolate is using a ball mill where the mass is milled and sheared at the same time. Although cocoa liquor is usually ground by ball mills, those are not popular for chocolate mass in the European industry. Nevertheless those systems are commonly used worldwide.

Particle Size Distribution Effects that Should be ...

rod mill gave a similarshaped size distribution to that of a closed circuit laboratory ball mill. He also demonstrated how a laboratory rod mill gave a similar shape of size distribution to a 36 inch ( m) Hardinge ball mill in closed circuit with a rake classifi er .

Pharmaceutical Suspensions

· Ball Mill: • It is used for size reduction fine solid discrete particles or for deagglomeration of very tightly bound agglomerates. • The machine consists of cylindrical drum into which a charge of heavy spherical balls usually metal or ceramic is loaded along with the components of the dispersion. 33.

classifier ball mill,5 micron,australia

Aximill provides a revolutionary new way of grinding and toll milling, capable of replacing ball mills, pin mills, jet mills, hammer mills, rotating disc mills, and others,, 34 Sydney Road Bayswater, VICTORIA 3153 Australia, through the Aximill 1000, sub 5 micron is delivered to the bagging system with no classifiion...

Bead Milling | Material Milling | Dispersion Processing ...

Bead mills are one of the most effective methods for processing fine particles into submicron or even nanometer size range. A wide variety of designs exist to adapt to the different viscosities, material characteristics and targeted particle sizes of dispersions.

Particle size reduction strategies to improve drug performance

· Particle size reduction strategies to improve drug performance. Micronisation, using fluid energy jet mills to reduce particle size, has been around since the 1960s and utilised by various different industries because it effectively produces micronsized particles with narrow size distributions, offers a low or negligible risk of contamination ...

Micro Powder Grinding Mill

· The final fineness of the grinding materials can be adjusted between 325 meshes and 2500 mesh (475 micron), and the product fineness can reach D97≤5μm. Environmentfriendly The appliion of pulse bag filter and muffler greatly alleviates dust pollution and noise.

YTZ GRINDING MEDIA

eliminates product contamination from both media and mill parts. Precise Milling Best Milling Performances Virtually no internal defects Outstanding wear resistance MEDIA SHAPE MEDIA SURFACE CROSS SECTION MICROSTRUCTURE Size (ϕ, mm) Size (ϕ, mm) 2 3 5 10 15 20 25 Bulk density (Kg/L) 3 ...

Food milling Equipment

Air classifying mills or jet mills can be suitable for ultrafine grinding and when you want to mill your foods to submicron levels we can help you with ball mill solutions. And when you are trying to reduce the particle size of a solid in suspension in a liquid, you may benefit from colloid or corundum milling .

Micro Ball Nose End Mill | BIG KAISER

Micro Ball Nose End Mill precision cutting tools capable of increasing productivity and meeting some of the most challenging appliion requirements. Sphinx micro cutting tools are produced using high quality, fine grain solid carbide with a reinforced shank diameter to maximize stability.

End Mills

End Mills. Micro 100's expansive offering of end mills feature square, ball, and corner radius profiles, as well as several different size, geometry, and coating options to ensure that the perfect solution your job demands is available to you.

MESH TO MICRON CONVERSION CHART

A micron is another measurement of particle size. A micron is onemillionth of a meter or one twentyfive thouh of an inch. Sieve Mesh # Inches Microns Typical Material 14 .0555 1400 28 .028 700 Beach Sand 60 .0098 250 Fine Sand 100 .0059 150 200 .0029 74 ...

Mechanical Alloying: A Novel Technique to Synthesize ...

Mechanical alloying is a solidstate powder processing technique that involves repeated cold welding, fracturing, and rewelding of powder particles in a highenergy ball mill. Originally developed about 50 years ago to produce oxidedispersionstrengthened Ni and Febased superalloys for aerospace and high temperature appliions, it is now recognized as an important technique to synthesize ...

Small end mills for highest performance

With NS Tool Mikron Tool has a found partner which perfectly complements its own line of business for over 60 years, this Japanese tool manufacturer bases its high level of expertise on decades of experience. Today they specialize in the development and manufacturing of highprecision small end mills made of solid carbide in the diameter range of mm to 40 .

Size Reduction Equipment

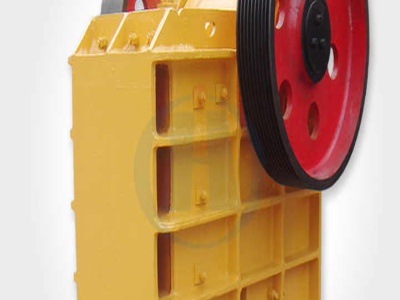

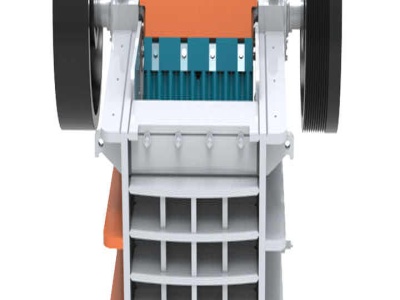

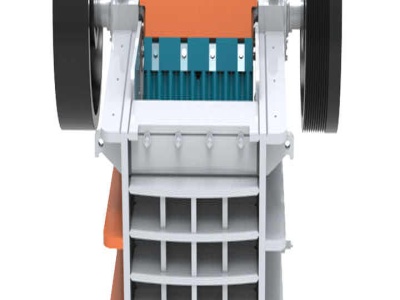

The product from a crusher is often fed to grinder in which it is reduced to powder. Grinders (Intermediate and Fine) 1. Hammer Mills 2. Rolling Compression Mills a. Bowl Mills b. Roller Mills 3. Attrition Mills 4. Tumbling Mills a. Rod Mills b. Ball Mill; Pebble Mill c. Tube Mills; Compartment Mills

Top 5 productspecific milling technologies used in ...

· Top 5 productspecific milling technologies used in industrial appliions. July 7, 2017. Find the best sizereduction methods for achieving the product goal. Rob Voorhees. ACM mill. All images courtesy of Hosokawa Micron International Inc.

Vertimill VS Ball Mill

Such mills normally have integrated classifier. This means plant design is more compact / simple in comparison to ball mill / classifier circuit. On the other hand fineness is limited. Agitated vertical mills. They have much higher specific grinding energy and from there are for production of finer products than conventional ball mills.

Industrial Ball Mills: Steel Ball Mills and Lined Ball ...

Ball Mills Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800's. The basic construction of a ball mill is a cylindrical container with journals at its axis.

Particle size reduction strategies to improve drug performance

· Micronisation, using fluid energy jet mills to reduce particle size, has been around since the 1960s and utilised by various different industries because it effectively produces micronsized particles with narrow size distributions, offers a low or negligible risk of contamination and generates no heat during processing

New concept for Torx®"

The four operations (prehole drilling – chamfering – milling – deburring) are completed in three operations with two tools. First the combined drill CrazyDrill Hexalobe does the center bore and a chamfer and this right away with an excellent surface quality (Ra µm, Rz µm). After the milling of the final shape, this tool will be used once again for deburring → a nearly burr ...

Catalent Micron Technologies

Catalent Micron Technologies is a leading international provider of particle size reduction and analytical services. We deliver firstclass pharmaceutical contract micronization, milling and analytical services combining quality, speedofresponse and industryleading expertise.. Catalent Micron Technologies has more than 25 years experience handling pharmaceutical materials .

Latest Posts

- سعر آلات تكسير الصخور للبيع أستراليا

- تعدين الجرانيت للتأجير أو للبيع في مصر

- استخدمت صغيرة كسارة الدوارة

- الكوارتز مسحوق الجسيمات رمل الحجم

- Raymond مطحنة للبيع الجزائر

- تحسين طاحونة الأسطوانة العمودية

- آلات كتل الخرسانة للبيع في كيب تاون

- الشركة المصنعة لآلة تكسير الكالسيوم الخفيفة

- تستخدم كسارة الحجر البائع السودان

- بيع ماكينة صناعة الجبس

- محطة المحمول الفك محطم

- أجزاء النبات محطم في الامارات

- خام الذهب الكسارات الصغيرة الصغيرة التعدين

- استخداما مطحنة الكرة في مصر

- بيع الساخنة الشهيرة كسارة الفك كسارة الصخور

- 1610 Jaw Mozambique Mozambique Price

- Q Mobile E Setting Screen Vibration

- Compact Concrete Crushers Rental Syria

- Ore Brazil Brazil Diagram

- Coconut Waste Crushing Machine Price In Sri Lanka

- Mobile Stone Crushers Brazil

- Used Costa Rica Jaw Costa Rica

- Plaster Processing Uzbekistan

- How Is Coal Mining Detected

- Sale Purchase Old Stone Brazil Machine

- Single Toggle Jaw Russia Working Principle

- Site For Finding Ppts On Crushing Machines

- Concentration Suriname Of Iron Ore Mining

- Small Portugal Parents To Buy

- Stone Sudan Cone For Sale In Usa