How To Fabrication Screw Brazil Pdf

Engineering Symbology, Prints and Drawings

This Portable Document Format (PDF) file contains bookmarks, thumbnails, and hyperlinks to help you navigate through the document. The modules listed in the Overview are linked to the corresponding pages. Text headings in each module are linked to and from the table of contents for that module. Click on the DOE seal below to move to the Overview. Department of Energy Fundamentals Handbook ...

Safety, Installation Service Instructions For SCREW ...

SCREW CONVEYORS Warning: Important information contained in this manual to be reviewed and followed by contractor, installer, owner and operator. 700 Hoffman St. 915 W. Ash 781 Church St. 7807 Doe Avenue Hammond, IN 46327 Chanute, KS 66720 Winona, MS 38967 Visalia, CA 93291 PH: PH: PH: PH: Fax: Fax: 800213 .

A Study of Plastic Extrusion Process and its ...

screw design has been improving over the years, with new innovations and ideas. Nowadays, single screws are available that have a secondary flights that improve speed by enabling faster melting. This process of extrusion serves two functions: it heats the plastic material above its melting point and puts the melt under pressure. The molten plastic material can then be forced .

SPECIFICATION FOR STUD BOLTS AND TAP END STUDS

inch screw threads per ASME (Revision of ANSI ) Standard. Size 1" and below shall have UNC threads. Size 11/8" and above shall have 8 threads per inch. APPLICATION API Spec 6A, "6B" flanges, may use "R" or "RX" gaskets, "RX" gaskets producing greater standoff between flanges. Tables for "6B" flanges in this document show stud bolt and tap end stud lengths that will ...

DESIGN AND FABRICATION OF A FEEDSTOCK DELIVERY SYSTEM .

hopper, screw feeder, stepper motor and feed injector. The hopper was designed to store a feed supply needed for continuous one hour operation of the reactor at the feed delivery rate of 15(±) gm/min. The screw feeder, which is rotated using a stepper motor, draws the feed particles from the hopper outlet and carries them in forward direction to the feed injector. The feed injector was ...

JANUARY, 2019 Trifab™ VG 450 / 451 / 451T INSTALLATION

The Screw Spline System is a fabriion and erection method that permits the preassembly of single units in the shop or at the job site. These units are then erected by mating the male mullion half of one unit with the half of the unit already installed. ELEVATION IS NUMBERED KEYED TO DETAILS Trifab™ VG 451T THERMALLY BROKEN MEMBERS 4 JAMB 5 .

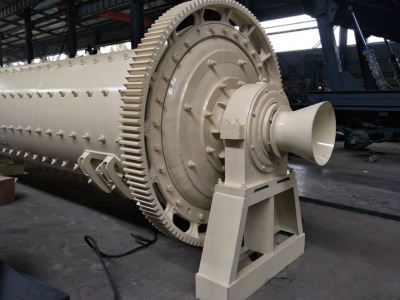

Design and fabriion of a screw conveyor | Request PDF

Request PDF | Design and fabriion of a screw conveyor | Grain transportation from one loion to another is exigent. Several disadvantages are associated with grain transportation, especially ...

SCREW CONVEYOR MANUAL

to describe them completely and these usually involve the fabriion of special hoppers, supports, drive equipment or other features to be with or as a part of the screw conveyor assembly. These Engineering drawings serve the dual purpose of detailing the special parts or components to be manufactured and to identify what is to be furnished for the buyer and .

DESIGN AND FABRICATION OF RACK AND PINION JACK

DESIGN AND FABRICATION OF RACK AND PINION JACK DHEEBAN KUMAR1, ANTONY AJITH2, P ... The jack's screw rod is fixed to the spear gear its combined more gears in one rod. The manual source power keys are interface with handle rod. Using this equipment, we can easily access the lifting of load in various purpose of our need. By alternating the power transmission with higher torque, .

Current Status of U3Si2 Fuel Elements Fabriion in Brazil

CURRENT STATUS OF U3Si2 FUEL ELEMENT FABRICATION IN BRAZIL M. Durazzo, Urano de Carvalho, SalibaSilva, Souza Centro do Combustível Nuclear Instituto de Pesquisas Energéticas e Nucleares, IPEN – CNEN/SP Av. Prof. Lineu Prestes, 2242 – Cidade Universitária – CEP, São Paulo – SP – Brasil and Riella Departamento de .

Honeycomb Panel Fabriion

screws must be suitable for the corresponding substructure. The screws should be tightened with a torque wrench or screw driver so that the sealing washer is placed on the panel for sealing the bore hole without exerting pressure onto the panel. Multistep drills or sleeves having corresponding diameters are used for centrically drilling holes into the panel and the substructure and for ...

Electroforming — a unique metal fabriion process

fabriion process and nickel is the dominant metal in this industry. It is beyond the scope of this publiion to provide all details of the procedures used to produce electroforms but the basic principles of the process and the reasons why nickel is so dominant are briefly explained. Appliions are described to demonstrate the versatility of electroforming in order that new appliions

SCREW CONVEYOR MANUAL

to describe them completely and these usually involve the fabriion of special hoppers, supports, drive equipment or other features to be with or as a part of the screw conveyor assembly. These Engineering drawings serve the dual purpose of detailing the special parts or components to be manufactured and to identify what is to be furnished for the buyer and installer. They are not to be ...

A GUIDE TO SHACKLES FOR LIFTING PURPOSES

These are utilized on screw pin and bolt type shackles to quickly check the approximate angle of a twolegged hitch, or quickly check the angle of a single leg hitch when the shackle pin is secured and the pull of the load is off vertical (side loaded), thus requiring a reduction in the working load limit of the shackle (See table 1). Side loaded rating reduction table for 3/16" 3" .

4. Fabriion

fabriion Alternatively, the frame could be secured using screws (Figure ). Figure : Assembling of window frame (Screw joint method) a) Jointing frame b) Tightening screw for joint All screws and screw holes for assembly of components should be sealed with sealant. Sealing pads should be

Pollution Prevention in Machining and Metal Fabriion

· Metal fabriion facilities generate solid waste in the form of broken pallets, cardboard boxes, and other packaging and shipping materials. Many of these waste streams may be recycled and facilities have set up separation programs to divert as much as possible from the solid waste stream to reduce waste disposal costs. Air Emissions The use of metal working fluids in metal shaping and .

Latest Posts

- التدريب على صيانة مصانع الكسارة الحجرية

- محجر الجرانيت في عمان للبيع

- خط إنتاج الجرانيت الطبيعي

- خط معالجة الذهب الصغير

- اختيار منطقة الفرز من الشاشة تهتز

- الصور من مخروط محطم

- آلة الجزائر تزود كسارة الحجارة

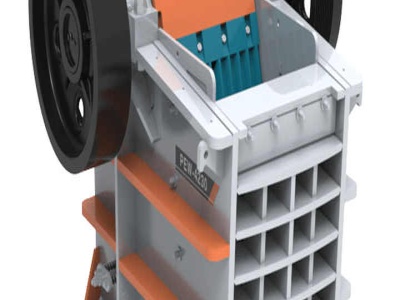

- جهة الفك حجر محطم

- مصر الفك الصناعي كسارة

- كسارة الفك نوع جرة صغيرة المحرز في عمان

- نوع جديد الرمال ماكينة

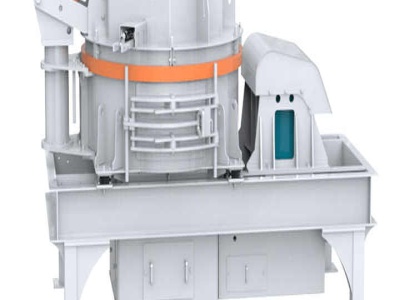

- تخفيض حجم المطحنة

- عملية رطبة لأسمنت بورتلاند

- مصانع استخراج الذهب من التعدين

- مصنع الجرافيت طحن آلة

- Plagioclase Raymond Mill For Sale

- Crushing Operation And Grinding Operation

- Used Sand Screeners For Sale In W Jamaica

- Jamaica Belt Design Guide Ppt

- Gravel Quarry Plant Manufacturer

- Vremeer Mobil Ston Cursher

- Pyrophyllite Grinding Mill For Sale Indonesia

- Stone Mozambique Plants In Mozambique

- Used Track Cone Crushers For Sale In Usa

- Sudan Grinding Plant Sudan Capacity Design

- Honduras Industries Steel Honduras Impact Honduras

- Equipamentos Para Extrac231227o De Uzbekistan

- Glass Crushing Spain Spain

- Jual Mobile Angola Surabaya Mining

- Red Sand Brick Moulding Machine In Malaysia