Dry Magnetic Separation Iron Mobile Plants

large dry magnetic separation plants

large dry magnetic separation plants Large Dry Magnetic Separation Plants Large Dry Magnetic Separation Plants. Material handling equipment a large lineup of material handling equipment for the recycling, metal stamping, plastics and food industriesmetal detection designed to monitor gravityfed products, pneumatically conveyed materials on belts, liquids .

Shielding Materials

First, one important point must be clear: Magnetic shielding does not block a magnetic field. No material can stop the lines of flux from traveling from a magnet's orth pole to it's south pole. The field can, however, be redirected. In the series of pictures below, follow the lines of flux as paths from one pole of the magnet to the other.

Dry Magnetic Separation Iron Mobile Plants

Dry low intensity magnetic separation dry drum separators have been developed mainly for dry separation of ferromagnetic ores with particle sies finer than 20 mm. In addition to this conventional appliion the dry drum separator has found a wide range of other appliions such as Iron and steel slag treatment

Industrial Magnetics Inc.

At Industrial Magnetics, Inc. (IMI), we specialize in industrial strength magnetic separation equipment for the removal of ferrous and nonferrous metal contaminants from dry or liquid product flows and we are the first manufacturer to offer 52 MgOe rare earth material as a standard in many of our metal separation products.

Methods of Separation | Separation Techniques

Separating funnel . Magnetic separation . Now we will discuss all above stated types of separation methods in detail – Handpicking (Image to be added soon) If you want to separate black grapes from the mixture of black and green grapes, then you will simply pick black grapes using your hands from the mixture.

Magnetic Separation | Multotec

Magnetic Separation. Multotec supplies a complete range of magnetic separation equipment for separating ferromagnetic and paramagnetic particles from dry solids or slurries, or for removing tramp metal. Multotec Dry and Wet Drum Separators, WHIMS, Demagnetising Coils and Overbelt Magnets are used in mineral processing plants across the world.

Dry Processing

Dry processing at Vale. In the last 10 years, Vale invested almost R66 billion in facilities and development of technologies for the dry iron ore processing production. Today, most of our iron ore production (about 60%) is through dry processing. The natural moisture processing is used at Carajás and Serra Leste mines, at S11D Eliezer Batista ...

dry magnetic separation iron mobile plant

Vale has inaugurated its new dry pilot plant for processing iron ore in Minas Gerais, Brazil, as it continues to reduce its use of water in ore and waste processing. The Brazilian technology, known as FDMS (Fines Dry Magnetic Separation), is unique and has been developed by New Steel – a company Vale acquired in late 2018 .

Iron Oxide Nanoparticles: Biosynthesis, Magnetic Behavior ...

· Iron oxide nanoparticles have attracted much attention because of their superparamagnetic properties and their potential appliions in many fields such as magnetic storage devices, alysis, sensors, superparamagnetic relaxometry (SPMR), and high‐sensitivity biomolecule magnetic resonance imaging (MRI) for medical diagnosis and therapeutics.

Dry Magnetic Separation Iron Mobile Plants

Mobile Magnetic Separator Iron Ore Plant With Magnetic. Dry magnetic separation iron mobile plants mobile jaw crusher plant mobile find the right and the top cobbing process of magnetic separation of iron mobile Products dry cobbing plant vianomoeu dry cobbing plant Quarrying Recycling Equipmen are perfect for primary and secondary crushing in stationary portable and mobile .

A discussion of magnetic separation techniques for ...

Dry magnetic separators, including both drum and roll types, generally offer far more precise separations than wet magnetic separators. Dry magnetic separation is more controllable since the separation medium is air rather than water. Separating particles from one another is naturally easier without having to fight drag forces created by water.

Sieving, Magnetic Separation

· In order to separate iron filling from sulphur,a horse shoe type magnet is moved on the surface of the mixture. The iron fillings are attracted by the magnet, they cling to the poles of the magnet and get separated. This process has to be repeated a number of times to achieve complete separation of iron filling.

Magnetic Separator

Explore Magnetic Separator for sale Australia wide on Australia's No1 online machinery classified. All Magnetic Separator posted here are either used Magnetic Separator or new Magnetic Separator. Browse more, so you can find Magnetic Separator that satisfy your needs!

Magnetic Separation

Magnetic separation takes advantage of the fact that magnetite is strongly magnetic (ferromagnetic), hematite is weakly magnetic (paramagnetic), and most gangue minerals are not magnetic (diamagnetic). A simple magnetic separation circuit can be seen in Figure [9].A slurry passes by a magnetized drum; the magnetic material sticks to the drum, while the nonmagnetic slurry keeps flowing.

Magnetic Separation

Magnetic separation takes advantage of the fact that magnetite is strongly magnetic (ferromagnetic), hematite is weakly magnetic (paramagnetic), and most gangue minerals are not magnetic (diamagnetic). A simple magnetic separation circuit can be seen in Figure [9].A slurry passes by a magnetized drum; the magnetic material sticks to the drum, while the .

Recyclable separation process |

· It employs a magnetic field induced electrons in aluminum, which interacts with the separator's magnetic field and pushes all aluminum waste on another conveyor, so it can be properly recycled. Once that is done, the only material that is left on the main conveyor belt is plastic, but since there are several types of plastic and not all of them can be recycled, that .

Top Rank Dry Magnetic Separator,

Dry Magnetic Separator Market 2021 Industry Size, The latest Market Research Inc study titled Global Dry Magnetic Separator Market highlights important aspects of the Dry Magnetic Separator Market The report is intended to help readers accurately estimate the growth rate of the world market during the forecast period ()

dry magnetic separation iron mobile plants

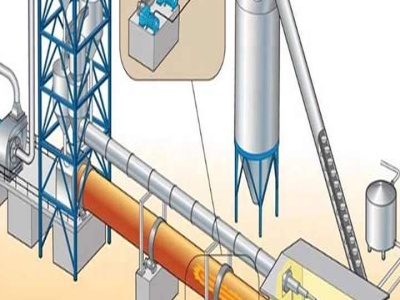

Magnetic Separation Plant ftmmachinery. Appliions : wet and dry type magnetic separation for materials smaller than 3 mm such as magnetite, pyrrhotite, roasted ore and titanic iron ore Case Description: The magnetic separation process is mainly made up of vibrating feeder, chute feeder, jaw crusher, vibrating screen, ball mill, classifier, magnetic separator, concentrator, and drying ...

Latest Posts

- قدرة كبيرة الكرة الاسمنت مطحنة

- تحتاج كسارة الحجر في البرد

- كيفية جعل طاحونة

- الموردين مصنع لتجهيز الحجر من المكسيك

- شركة طاحونة مصر

- آلات التكسير رخيصة وأسعار

- تأجير المسمار المحمول الرمال Nsw

- مطحنة الكرة تعدين الذهب للبيع الصين على نطاق واسع

- فارما الصغيرة المصنعة الطاحن

- بناء ملموسة سحق المعدات

- المعاصر الجديد سكاكين مطحنة قضبان الأسلاك

- فتحت تغذية كسارة الحجر

- كسارة الحجر المحمول مصر سعر

- إجمالي التكلفة م مصنع الرمل

- كسارة ثانوية من الزنك

- Stone Sand Washer Manufacturer

- Chile Grainding Ball Mill Unit

- Two Crushing And Screening Guyana Prices

- Blue Metal Jamaica Price

- Bolivia Plant For Bolivia Plant

- the Philippines Plant Silicon Quartz

- Diagramas Flujo Bodega

- Gold Roller Guyana For Sale In Guyana

- Type Of Jow Crushers And Various Sizes

- What Is A Cs Series Stone Cone Uzbekistan

- Stone Crushing Production Line Capacity 600tph800tph

- Gold Mining Syria Portable Grinder

- Double Roll Saudi Arabia Vendor

- Crushing And Screening Plant Uses In Construction

- Used Stone Grinder Angola Angola