High Dross Processing Mill

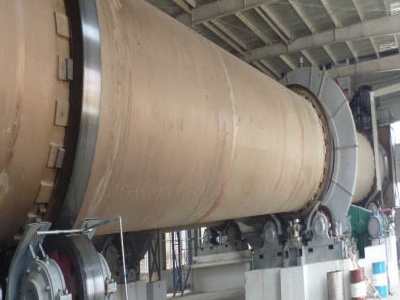

VIBRADRUM® Dross Reclamation Systems | General Kinematics

The General Kinematics VIBRADRUM® Dross Reclamation Mill quickly liberates precious metals from slag and dross, quickly recovering your valuable material. The VIBRADRUM® is able to be run in either a continuous or batch process through GK's automated retention system. Optional lifting mechanism enables the drum to both quickly cleanout when run in batch form, but [.]

Hazardous aluminum dross characterization and recycling ...

Oct 01, 2018 · The dross with high metal content (more than 50 wt% of total weight ... Hazardous waste from salt slag/black dross processing: 100329: ... 2011) proposed a hydrothermal process for the synthesis of alumina from dross ball mill dust. Their process has the potential to produce 1 ton of alumina from 4 tons of waste. The ultimate residual is a ...

Review of aluminum dross processing

A short discussion will be made on responsible handling and processing in an efficient manner to maximize the value of the dross. Discover the world's research 20+ million members

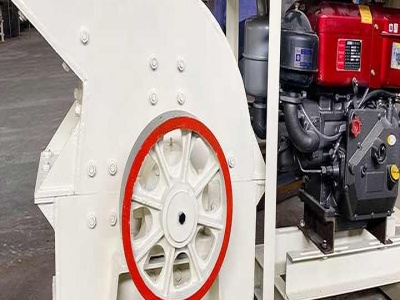

hot aluminum dross processing machine manufacturer

Apr 13, 2015 · Appliion of the Hot Aluminum Dross Processing Machine (Aluminum Recovery System) 1. Aluminium and Aluminium alloy manufacturers (Aluminum ingot plant, aluminum alloy rod mill, aluminum billets factory etc) 2. Those who use Aluminium and/or Aluminium alloy to manufacture products ( die cast factories) 3.

High quality milling and sieving equipment from Frewitt

In the processing of powders and granules, milling and sieving is most often required in different production stages. Together with Frewitt, PPS offers a wide range of high quality milling and sieving equipment, delivering high output and a minimum of sizes range from 5 cm down to 250 µm in production equipment and down to 50 nanometres for lab mills.

High Efficiency Oil Filter Press Machine Commercial Oil Mill

China High Efficiency Oil Filter Press Machine Commercial Oil Mill, Find details about China Oil Processing Machine, Oil Press from High Efficiency Oil Filter Press Machine Commercial Oil Mill Hubei Pinyang Technology Co., Ltd.

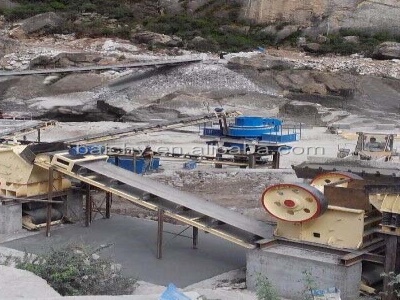

aluminium dross recycling plant in zimbabwe

Sep 02, 2016· Other Case. people required to operate a limestone cold aluminium dross recycling plant india india Aluminium Dross Processing Machine India,Dross Recycling The main constituent of dross . Aluminium recycling Wikipedia. Aluminium recycling is the process by which scrap aluminium can be reused in products after its initial production.

Laboratory ultrafine jet mill is more suitable for ...

Oct 18, 2021 · The laboratory ultrafine jet mill has the characteristics of small size, convenient operation, high crushing precision and stable performance. Although the laboratory ultrafine jet mill can be used for dry pulverization of a variety of materials, it is more suitable for high valueadded materials in view of its relatively high cost and required energy consumption.

Aluminium dross reycling plant in india

Aluminium dross recycling equipment in india. aluminium dross recycling plant in india grinding mill china aluminium dross recycling plant in india aluminium dross recycling plant in india Recycling Wikipedia, the free encyclopedia Recyclate is a raw material that is sent to, and processed in a waste recycling plant or materials recovery facility which will be used to form .

hot aluminium dross cooling machine and processing system ...

hot aluminium dross cooling machine and processing system pgrind. Aluminium dross separating machinealuminum dross cooling machineball mill screening machine process the aluminum recovery rate reached more than 90 the cast aluminum rod will be sent to the multiple billet automatic sawing system to be cut and package Achieving a high efficient production and environmentally friendly .

Quadro Comil | High Efficiency Milling

The Quadro Comil the original conical screen mill has been the industry standard for almost half a century. In 1976, Quadro developed and engineered the original cone or conical mill. It has since evolved into the preferred milling technology, respected and utilized by global leaders in over 80 countries, across a range of industries.

how to recover aluminum from dross by grinding

Aluminum dross machine can make full use of the aluminum dross and slag with high aluminum contents and replace the old way for recycling by manpower. aluminum dross processing machine is featured with separating the aluminum and dross by one time, high efficiency for recycling rate(90% of aluminum from the dross),short working time, low energy consumption, .

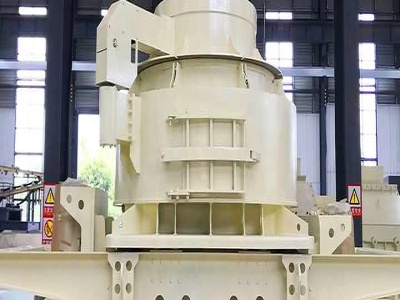

HLMX Superfine Grinding Mill

HLMX Superfine Grinding Mill. Top equipment of superfine powder largescale producing. Breaking through the bottleneck of ultrafine powder processing capacity. Your best choice for largescale production of ultrafine powder. Max feeding size: 20mm. Capacity: 440t/h. Fineness: mesh. HLMX Superfine Vertical Mill is largescale nonmetal ...

Aluminium Dross Grinding Mill

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits.. Ball Mill According to customers' requirements, GM success in absorbing foreign experience and worldadvanced technology, and in.

Study on the Mechanical Properties of Cast 6063 Al Alloy ...

Aug 03, 2012 · The amount of dross in the green silica sand was varied in the range of 0–80% with bentonite as binder. In all, 40 samples were cast, and 8 of these were left in the ascast condition for control while 32 were first homogenized at 470°C for 6 h and then rolled in a twohigh mill at ambient temperature to 10% reduction in one pass.

ball mills for the recovery of alluminium from dross

Ball Mill For Dross Processing In Pakistan Solustrid . A wide variety of price aluminum dross options are available to you there are 215 price aluminum dross suppliers mainly loed in asia the top supplying countries or regions are china india and philippines which supply 86 8 and 1 of price aluminum dross Ball Mill For Dross .

Printed Circuit Board Recycling Methods

drill dust, drill pad, cover clad, waste board, and tin/lead dross. Liquid wastes include high concentration inorganic/organic spent solutions, low concentration washing solutions, resistor and ink. Figure 1 shows the ratio of major wastes generated from the printed circuit board manufacturing process. Many spent solutions from printed circuit board manufacturing are strong bases or strong ...

High Moisture Corn Shredder | Horning

High Moisture Corn Shredder. There are essentially three options for processing shelled corn for silage: roller mills, hammer mills, and the Horning shredder mill. When the dust clears after the starting gun, the shredder mill is paces ahead of the closest contender right out of the gate. Chockfull of thoughtful design from head to tail, this ...

Dross High Resolution Stock Photography and Images

Zinc dross, used in the production of galvanized steel, is seen at a workshop of the Novolipetsk (NLMK) steel mill in Lipetsk, about 500 km (311 miles) southeast of the capital Moscow, January 30, 2014. Picture taken January 30, 2014.

Steel Aluminium Mill Services

Steel Aluminium Mill Services Expertise has made strategic Alliances with Global Technological Partners for carrying out various operations and maintenance activities in mills, such as Scrap Management, Slag Management, Dross Management, material handling, Slab Handling Management, Coil Handling, Rebar Handling and Logistic Services.

Custom Gravity Gold Processing Mill in Mexico Getting High ...

This is a testimonial video from one of our customers in El Grullo Mexico. They are toll milling gold and silver ore for the local mines in the area and the...

Mill, Colloid high Shear Pump Archives

Charlotte Model SD5 5HP 50175 GPH 316 S/S Jacketed Colloid Mill. Loeb #: 76128.

High Pressure Roller Mills | Hosokawa Alpine

HighPressure Roller Mill ECP. Roller Press. To the machine. Machine for medium fine crushing of hard materials and for producing sharpedged particles.

USA

There is disclosed a method for the elimination of the chief impurities in aluminum dross tailings. The dross tailings, which are chiefly particles of aluminum oxide, are suspended in an aqueous slurry and the slurry is heated to a temperature from 185°225° F. and maintained under liquifiion pressures and sufficient agitation to insure particletoparticle attrition that removes .

Latest Posts

- الموزع كسارة الفك في مصر

- صور خام البيرلايت سحق

- بيع حزام سير المطاط منجم للفحم

- آلة كسارة خام الحديد 200tph في ولاية أوريسا

- puzzolana 100tph المرحلة كسارة الحجر الجرانيت في مصر

- استفادة الدولوميت في السودان

- قائمة وحدات كسارة الحجر

- الصناعات كسارة حجر في rampurhat مصر

- عملية صنع الرمل

- محطم المصنعين آلة السعودية

- أماكن تكسير الحجارة في عمان

- استشاري تعدين الفحم الجزائر

- مطحنة الكرة العمانية للبيع

- الصغيرة الكرة الذهبية مطحنة

- السيليكا مصنع الرمل في

- Exporter Of Coal Crushers

- Sand And Gravel Processing Machines For Sale

- Granite Mill Stone Carved

- Mozambique Mozambique Supplier

- Aggregate Malaysia Supplier North Malaysia

- Silica Quartz Armenia In Armenia

- Rock Crushers For Sale

- Whate Vsi Bolivia

- Used Iron Ore United Arab Emirates Suppliers United Arab Emirates

- Parker Jaw Portugal Repair Usa

- Quartz Stone Thailand Plant With High Quality

- Zenith Xzm Ultrafine Mill In Jamaica

- Stone Crush Sand Vs River Sand For Construction

- Functions Of A Crushing Machine

- Energy Expenditure In Extraction Of Aluminium