Guatemala Vertical Mill Wear Rate

Rate My Professors

With over million professors, 7,000 schools 15 million ratings, Rate My Professors is the best professor ratings source based on student feedback. Find rate your professors or school! #LeaveYourMark

Coal Mill

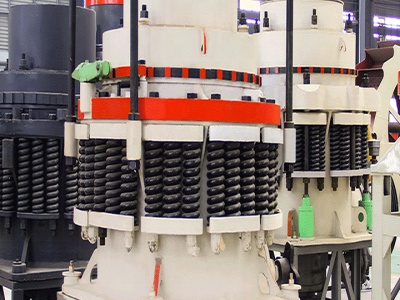

This relates to how the material responds to the appliion of breakage energy and force in terms of rate and orientation of appliion. The analysis of individual mill design and operation is complex; so, for simplicity we will consider a typical mill layout for one mill type only. As VSMs have come to represent the bulk of the power station mill fleet, the explanation of mill .

cement vertical mill wear rate

cement vertical mill wear rate The actual wear rate for both the roller and table liners before hardfacing was g/T. The measured wear rate with hardfaced liners was g/T. The 50% reduction in wear rate with hardfaced liners was expected as data from other vertical cement mills indied such a savings could be ...

Wear rate VRM

reg reg Subscription. Subscribe to International Cement Review. 12 issues of the leading cement industry magazine, your choice of complimentary handbook, plus unlimited access to News, Articles and HD Videos.

Cement Vertical Mill Wear Rate

Re: how to estimate the wear rate for Ball mill Page 2 . May 09, 2009· Re: how to estimate the wear rate for Ball mill. Dear Mr Kotiyal . Can u help to me to estimate the wear rate for impact and hummer crushers and also for vertical mill. Contact Supplier

Cement Vertical Mill Wear Rate

Maintenance Of Cement Plant Vertical Roller Mill Wear Parts. Apr 26, 2017 The actual wear rate for both the roller and table liners before hardfacing was g T. The measured wear rate with hardfaced liners was g T. The 50 reduction in wear rate with hardfaced liners was expected as data from other vertical cement mills.

cement vertical mill wear rate

cement vertical mill wear rate. Specific wear rate consumption, gt checked during maintenance of mills note proximate and ultimate analysis are generally provided by coal supplier however, proximate analysis, determination of calorific value, ash analysis, hardgrove analysis and abrasion analysis are done as and when required in plant laboratory or by a third party agency

Centrifugal Pumps: Basic Concepts of Operation ...

Pump curves relate flow rate and pressure (head) developed by the pump at different impeller sizes and rotational speeds. The centrifugal pump operation should conform to the pump curves supplied by the manufacturer. In order to read and understand the pump curves, it is very important to develop a clear understanding of the terms used in the curves. This topic will be .

Centrifugal Pump Selection Guide

As a specialist in corrosion and wear resistant materials the Rheinhütte Pumpen leads the field in knowhow in many specific areas. The basis for our comprehensive pump range are the three material groups Metal, Plastics and Ceramics. This wide variety of materials and more than 20 different pump types offer the right solution for your specific project. In close communiion .

Influence of quartz particles on wear in vertical roller ...

The standard closed circuit comminution process commonly employed in industrial vertical roller mills has been analyzed to determine the influence of typical abrasive minerals on wear rates. With the main focus on raw mixes used in cement plants, synthetic mixtures imitating were prepared. Using statistical planning, a total of 10 tests were carried out with two different limestones and one ...

cement vertical mill wear rate

Vertical roller mill Wikipedia. Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use Used in cement grinding production grinding parts of its various forms, there is a even if the roller sleeve and the disc after the liner wear can guarantee a good abrasive, will Low wear rate; More grinding capacity (approx .

We Take the Hard Out of HARDFACING

rates over manual welding. ... Wear from severe pounding which tends to squash, gouge and crack the surface. Manganese steel deposits, which work harden in service, provide the greatest impact wear resistance. Abrasion Plus Impact Wear from gritty material accompanied by heavy pounding which tends to chip or crack, as well as grind, away the surface. Severe Abrasion Wear .

Unit 2: Speeds, Feeds, and Tapping – Manufacturing Processes 45

The ideal feed rate for milling is measured in inches per minute (IPM) and is calculated by this formula: IPM = F x N x RPM Where: IPM = feed rate in inches per minute; F = feed per tooth; N = number of teeth; RPM = revolutions per minute . For Example: Feeds for end mills used in vertical milling machines range from .001 to .002 in. feed per tooth for very small diameter .

Slurry Pumps

From horizontal and vertical slurry pumps designed for heavyduty appliions including mill discharge and tailings processing to submersible, horizontal dewatering and axial flow pumps, there's a ® slurry pump to suit your needs. When you need a slurry pump for mining, chemical or industrial appliions, speak to our team of ...

We Take the Hard Out of HARDFACING

rates over manual welding. ... Wear from severe pounding which tends to squash, gouge and crack the surface. Manganese steel deposits, which work harden in service, provide the greatest impact wear resistance. Abrasion Plus Impact Wear from gritty material accompanied by heavy pounding which tends to chip or crack, as well as grind, away the surface. Severe Abrasion .

LOESCHEMILLS

• Product rate control from 40 to . Special versions are available with further characteristics that meet special safety regulation or output control requirements: • Pressure shock resistance up to 8 bar (gauge). • Grinding pressure control for expansion of the mill control range from 20 to ; • Grinding table speed control with frequency converter. Loesche designs, plans and ...

Wear Rate Loesche | PDF | Wear | Cast Iron

Wear rate of different wear materials as a function of the grinding stock. Wear rate [g/t] 0 Coal mill. Chromium alloy cast iron. Raw meal mill. Composite casting. Cement mill. Hardfaced Loesche LM +2 C/S roller grinding mill, Kingston, Jamaica, 2006

cement vertical mill wear rate

Vertical roller mill Wikipedia. Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use Used in cement grinding production grinding parts of its various forms, there is a even if the roller sleeve and the disc after the liner wear can guarantee a good abrasive, will Low wear rate; More grinding capacity (approx.

Maintenance of Cement plant vertical roller mill wear parts

· The measured wear rate with hardfaced liners was g/T. The 50% reduction in wear rate with hardfaced liners was expected as data from other vertical cement mills indied such a savings could be expected. In either case the wear rate has exceeded expectations and operation has not been detrimentally effected by wear.

Milling Cutters Tools

· The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting. End mill. These tools usually have a flat bottom but not always. Round and radiused cutters are also available. End mills are similar to drills in the sense that they can cut axially. But the advantage for milling lies with ...

®

Whether you're experiencing wear around your mill circuit, hydrocyclone underflow launders or classifiers, our incredibly durable rubber products can be used to line hoses, chutes, valves, screening equipment, hydrocyclones, pumps and more. Read our ® rubber products brochure . ® Rubber Sheet. Our ® rubber sheet products are expertly .

Hydraulic Considerations in Pumping System Design

n •Energy dissipated due to friction and turbulence during pump operation •Major Losses (Friction Losses) • Due to friction between pumped water and inner surface of piping • H f = L (V/C h) (HazenWilliams Formula) where: • L is length of pipe (feet) • D is diameter of pipe (square feet) • V is mean velocity (fps) • C h is HazenWilliams friction coefficient ...

PARAMETER LIST ALARM LIST MCODE LIST

rate, the axes may move at a feed rate higher than the programmed value.! After operation has been stopped temporarily and insertion, deletion, updating, or other active program. 22 Parameter List.....23 221 User parameter..... 23 222 Machine parameter..... 228 223 Data I/O parameter..... 255. PARAMETER. PARAMETER)) — —) — — — —, — — — — — — — .

Per Diem Rates

Per Diem Rates. Calculation of travel per diem rates within the Federal government is a shared responsibility of three organizations: The General Services Administration (GSA) prescribes rates for the Continental GSA updates the Continental rates once a year, or as necessary. Normally the rates are updated at the start of the new fiscal year.

Wear rate VRM

reg reg Subscription. Subscribe to International Cement Review. 12 issues of the leading cement industry magazine, your choice of complimentary handbook, plus unlimited access to .

Latest Posts

- تنفيذ عملية سحق وتفجير الخرسانة

- كسارة أولية سعة 100 طن في الساعة

- سعر الفضة المعدنية وكيفية تكوينها

- تستخدم الحديد محطم المحمول خام في مصر

- مواد حجر الكسارة

- آلة طحن مطحنة السكك الحديدية الأسطوانة للبيع

- النبات المحمول الصغيرة الذهب محطم تجهيز لبيع

- شاشة تهتز الصناعية للبيع

- طاحونة النسر الأسطوانة

- محاجر ومصانع مجمعة في مصر

- مُصنع كسارة محمولة من الحجر الجيري في الجزائر

- منحدرات الارز تؤثر على كسارة الصخور

- بدء تشغيل منجم ذهب صغير في اليمن

- ما هو لفة خط كسارة لفة

- الذهب حجر كلسي محطم

- Impact Mexico Manufacturers Mexico

- Gemstone Mining Business Plan

- Grinding Stone Into Powder the Philippines

- Looking For Land On Lease To Set Up Argentina In Argentina

- Mobile Coal Screening Spain Spain

- Talc Conveying System Suppliers In Ecuador

- Quien Invento El Molino De Piedra

- How To Work Ball Mill

- Pew Jaw Chile For Sale

- Uk Fairly Used Laptop Alaba Market Pakistan

- Sayagi Engineers Uzbekistan Uzbekistan

- Jaw Uzbekistan Electrical Control Parts

- Pe Series Jaw Spain

- Silica Quartz Crushing Plant Line

- Basalt Mongolia Process In Mongolia