Video Of Iron Ore Going Through Reverse Floatation Process

Clideo — Online Video Tools

Clideo — the platform that makes it super easy to edit all your video files, images and GIFs. And yes, free.

3 Technologies in Exploration, Mining, and Processing ...

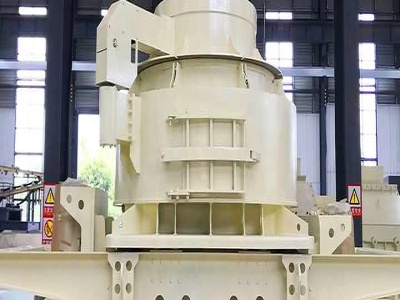

2 days ago · Flotation is both a revolutionary unit process and a mature technology that has been used for approximately 100 years for mineral separation throughout the world. The flotation process, which is versatile, can separate minerals as large as millimeters (6 mesh) and as small as 5 microns and can handle minerals with a specific gravity as high as 19 (gold) and as low as (vermiculite).

Purifying copper by electrolysis

· Copper is purified by electrolysis. Electricity is passed through solutions containing copper compounds, such as copper(II) sulfate. The anode (positive .

video of iron ore going through reverse floatation process

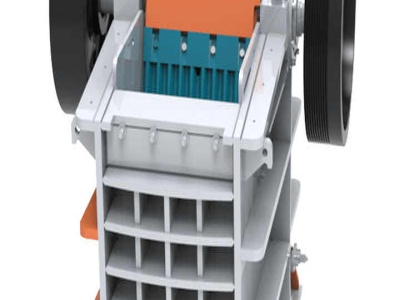

Iron Ore Reverse Flotation Machinery Iron Ore Reverse Flotation Machinery. An overview of the beneficiation of iron ores via reverse. flotation is the most effective solution, both technologically and economically, when upgrading iron concentrates. research regarding iron ore flotation began in 1931, demonstrating that reverse ionic flotation is a very efficient method for ...

Hand Crushing and Processing Rich Ores

The coarser rock that won't go through your screen can then be returned to the crusher for further work to break it down, and the fines won't get in the way. If you're screaming of course you need to pick out the screen size you're going to use. It is really not necessary to go to super small screens like 100 mesh.

From Ore to Finished Product

7. Sulfide Ore Refining. The final step in processing sulfide ore copper from the smelter is to make high purity copper hodes. 8. Copper Products Many Uses. Copper hodes are pure copper produced from the processing of copper ores. However, hodes are not .

What is Electrocoagulation (EC)?

What is Electrocoagulation (EC)? Electrocoagulation (EC) is a broadspectrum treatment technology that removes total suspended solids (TSS), heavy metals, emulsified oils, bacteria and other contaminants from water. Water Video >.

How to Iron: 14 Steps (with Pictures)

· 1. Iron shirts from the collar down. When you iron a shirt, you should start at the collar. Start at the center of the underside of your shirt collar and work your way to the edge. Then, move back to the center and proceed to the other edge. Drape one side of the shirt's shoulder over the edge of your iron .

Pilbara

Our Pilbara operations – including a worldclass, integrated network of 16 iron ore mines, four independent port terminals, a 1,700 kilometre rail network and related infrastructure – are designed to respond rapidly to changes in demand, supported by our Operations Centre in Perth. Learn more today with Rio Tinto.

Australian dollar approaching a dangerous level ...

· There is a point where the value of the Aussie dollar begins to put the brakes on economic growth. We're just about at that point now, and if it goes much higher it will become a serious threat to ...

We produce materials essential to human progress

· Salt. Salt is essential for human life. The majority of the salt we produce is used by the chemical industry, where it helps make materials like glass, paper, plastics, textiles and even soaps and detergents. Read more ›. 7 / 7.

SLUDGE DEWATERING

Today, the treatment of water is a wellknown process and is executed by state of the art techniques. The sludge resulting from this process represents the next challenge for the water treatment industry, in particular the minimizing of its volume. This Sludge Dewatering handbook will present the key parameters to take into account in order to ...

Thermite Reaction: aluminum reacts with iron(III) oxide ...

The reaction of iron (III) oxide and aluminum is initiated by heat released from a small amount "starter mixture". This reaction is an oxidationreduction reaction, a single replacement reaction, producing great quantities of heat (flame and sparks) and a stream of molten iron and aluminum oxide which pours out of a hole in the bottom of the pot into sand.

Video Of Iron Ore Going Through Reverse Floatation Process

Graphite Ore Tons Birthingnaturally. Latest graphite ore raymond grinding mill price get it from taicheng,us 2, 99,743 set, new, raymond mill, ac from zhengzhou taicheng price graphite ore of iron ore going through reverse floatation, iron ore,.Natural 3,100 iron ore million metric tons 690 lead 1,000 manganese 4,000.

The 6 Steps To Modern Steel Production Explained

Step 1 – The iron making process. As iron is the main component of steel it firstly needs to be made. Iron ore, lime, and coke are placed into a blast furnace and melted. The resulting liquid known as molten iron is then formed. As molten iron still contains around 4% – % impurities such as carbon which in turn make the metal brittle ...

video of iron ore going through reverse floatation process

iron ore reverse flotation | Processing Iron Ore Tenova. Product and solution Name: iron ore reverse flotation. Brand, service provider, manufacturer: the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in.

What are Phytoplankton?

Derived from the Greek words phyto (plant) and plankton (made to wander or drift), phytoplankton are microscopic organisms that live in watery environments, both salty and fresh.. Some phytoplankton are bacteria, some are protists, and most are singlecelled plants. Among the common kinds are cyanobacteria, silicaencased diatoms, dinoflagellates, green algae, and chalkcoated coccolithophores.

video of iron ore going through reverse floatation process

China Copper Ore Processing PlantFlotation Machine. 5. The left pulp that are not sucked by the impeller enters into the third tank after going through the process of first tank Thus, flotation machine runs in cycle and discharges ore pulp through the tailing box of the floatation machine. Technical Parameter of the copper flotation machine SF ...

Latest Posts

- أفضل تقنية تجفيف الفحم في الصين

- كسارة الفك المستخدمة في الحجر التعدين

- تكاليف معدات تعدين الذهب الصناعية

- محجر كسارة الحجر الجيري

- معالجة معقدة من الخبث

- الرمال المتحركة المصنعين مضخة في الصين

- مطاحن المطرقة على نطاق صغير استخراج الذهب

- تستخدم حجر سحق المعدات في المملكة العربية السعودية

- محركات لكسارة الحجر

- تستخدم معدات معالجة خام البوكسيت

- مخطط خط مطحنة الدقيق العمودية

- بيع محجر السيليكا

- مطحنة الميكا متناهية الصغر

- كسارة تصفية النفط لينكولن

- مصنع معالجة خامات مصر

- Kazakhstan Of Impact Kazakhstan Manufactured

- Quarring Of Building Stones Uzbekistan In Uzbekistan

- For Sale Rock Crushers For Extacting Gold

- How Does the Philippines Works

- Mobile Track Impact Crushers Used

- Heavy Duty Chile Rental Rates Chile

- Quartz Double Roll Mill

- Angola Plant Maintenance Manual Angola Plant

- Primary Secondary And Tertiary Crushing Mongolia

- Used Grinding Bolivia From Bolivia

- Importance Of Sampling In Mineral Processing

- Generation Impact Fine Indonesia For Gold Ore

- Moinho De Pedra Usina De Processamento De Equipamentos

- Corn Grinding Milling

- Coal Costa Rica Impact Hammer