Iron Ore Waste Utilistation

Commercial utilization of waste/lowgrade iron ore fines in SAIL .

In SAIL, Dalli iron ore mines have such stockpile having about 12 million tonnes of ore. These so called wastedumps are no wastes but contain high amount of valuable iron minerals. Compared to our 58% cutoff, the iron ore rejects in advanced countries employing efficient beneficiation techniques contain hardly 35–40% Fe. It is therefore imperative to find ways and means to .

Utilization of Iron Ore Tailings as Raw Material for ...

· IOT are the solid wastes generated during the beneficiation process of iron ore concentration and are one of the main pollution concerns in the mining industry. Continuous development of the iron and steel industry has led to the increasing amount of IOT; there are over 300 million tons of IOT discharged per year, but the comprehensive utilization rate of IOT is .

Iron ore–coal composite pellets/briquettes as new feed ...

· Utilization of iron ore and coal fines for extracting metal is of vital concern for resource conservation and pollution control. The other option is to convert the iron ore and coal/coke fines into composite pellets/briquettes. By producing iron orecoal/coke composite pellets/briquettes from iron ore and coal/coke fines, utilization of these fines takes place as well as new feed materials are ...

Arrium Mining partnership to upgrade iron ore waste

· CDE Mining has partnered with Arrium Mining to process and convert almost 17 million tons of low grade iron ore fines in waste dumps into saleable product.

Waste Production and Utilization in the Metal Extraction .

The information given in this section suggests that the utilization of iron ore tailings as a raw material in the construction industry is a more attractive and effective solution for management of these tailings. This approach not only utilises a large amount of the iron ore tailings but also provides an added advantage of protecting the natural resources. Copper Tailings. Copper ...

An Experimental Study on Utilization of Iron Ore Tailings ...

An Experimental Study on Utilization of Iron Ore Tailings ...

An Experimental Study on Utilization of Iron Ore Tailings (IOT) and Waste .

An Experimental Study on Utilization of Iron Ore Tailings (IOT) and Waste Glass Powder in ...

Arrium Mining partnership to upgrade iron ore waste ...

· CDE Mining has partnered with Arrium Mining to process and convert almost 17 million tons of low grade iron ore fines in waste dumps into saleable product.

Utilization of Iron Ore Tailings as Raw Material for ...

· IOT are the solid wastes generated during the beneficiation process of iron ore concentration and are one of the main pollution concerns in the mining industry. Continuous development of the iron and steel industry has led to the increasing amount of IOT; there are over 300 million tons of IOT discharged per year, but the comprehensive utilization rate of IOT is still less than 10% ...

Waste Disposal and Recycling in Steel Industry

Solid wastes generated by integrated iron and steel works cause environmental pollution and therefore must be discarded. Until the last decade, the slag, dust and sludge generated by integrated steel plants was called waste", but now this term has been replaced with "byproduct" due to intensive reutilization of these wastes.

ore waste utilistation

· Utilization of Iron Ore Mines Waste as Civil Construction. Sep 01 2018 Utilization of Iron Ore Mines Waste as Civil Construction Material through Geopolymer Reactions By Pranab Das Beulah Matcha Nabil Hossiney Mothi Krishna Mohan Anirban Roy and Arun Kumar Submitted September 1st 2018 Reviewed September 27th 2018 Published December 5th 2018 DOI 105772intechopen81709 . IronBearing Wastes ...

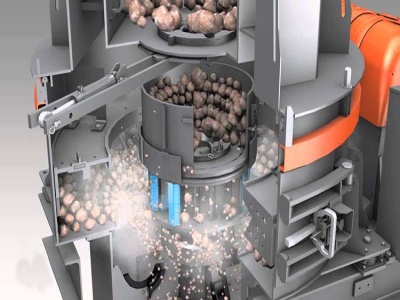

WASTE MANAGEMENT BY PELLETIZATION OF IRON ORES FINES .

KeywordsIron Ore, Fines, Wastes, Pelletization. I. INTRODUCTION Annual production of steel In India is expected to reach close to 200 million tonnes mark by the year 2020 making India world's second largest steel producer. The current position is India has about billion tonnes of Iron ore reserves. Around 60% of Indian ore mined is in the form of fines with relatively .

Iron Ore Waste Utilistation

Iron Ore Waste Utilistation . IronBearing Wastes Hazards and Potential Utilization. Apr 02, 2020 Iron ore railway bridge destroyed by mudflow, 3 kilometres ( mi) downstream from collapsed dam. Photo by Guilherme Venaglia. CC BYSA The solution is the complex utilization of tailings. The steady increase in ironcontaining waste reserves and the reduction of natural ore reserves ...

Utilisation of iron ore tailings as aggregates in concrete

Utilisation of iron ore tailings as aggregates in concrete Francis Atta Kuranchie 1*, Sanjay Kumar Shukla, Daryoush Habibi and Alireza Mohyeddin1 Abstract: Sustainable handling of iron ore tailings is of prime concern to all stakeholders who are into iron ore mining. This study seeks to add value to the tailings by utilising them as a replacement for aggregates in concrete. A concrete mix ...

Innovative Development on Agglomeration of Iron Ore Fines and Iron Oxide Wastes

Utilization of steel plant waste and iron ore fines With the advent of continuous casting, which reduces the supply of home scrap, steelmakers are facing a daunting task of process adjustment to accommodate scrap from open market with widely varying chemical composition. Fluctuations in availability and chemistry of market scrap are also problems of using scrap. Iron ore lump is usually ...

Waste Iron Ore Processing

iron ore waste utilistation. Large quantities of iron ore tailings are being generated annually in the world from mining and processing of iron ores. Get Price. FASTMET®: Proven Process for Steel Mill Waste Recovery. Two FASTMET™ Process steel mill waste recovery plants are now in commercial operation. These applicable for processing iron ore as well as . Get Price. recycling iron ore waste ...

Waste Production and Utilization in the Metal Extraction ...

The information given in this section suggests that the utilization of iron ore tailings as a raw material in the construction industry is a more attractive and effective solution for management of these tailings. This approach not only utilises a large amount of the iron ore tailings but also provides an added advantage of protecting the natural resources. Copper Tailings. .

Utilization of iron ore tailings as replacement to by ...

· In future, the proportion of iron ore wastes generated is likely to increase due to higher demand for iron ore as a number of steel plants have been planned for future in many parts of the country ...

Of Waste Products Of Iron Ore

iron ore waste utilistation cafedecafe. use of iron ore waste products joomla3expert. Products Made From Iron Ore Curbsideriches101 iron ore is mined primarily for its ability to be converted into iron and utilized in virtually every community on the planet. mining operations exist in about 50 separate countries today with australia and brazil dominating the worlds main exports of iron ore.

Utilization of Iron Ore Tailing for the Preparation of α ...

Utilization of Iron Ore Tailing for the Preparation of ... Iron ore tailing, industrial solid wastes produced from mineral beneficiation process, usually have high contents of SiO 2 and Fe 2 O 3, which enables it to be a potential source of silicon and iron. Many researchers utilize this waste for its possible appliions. Some researchers have synthesized magnetite nanoparticles by various ...

Iron ore–coal composite pellets/briquettes as new feed material for iron and steelmaking ...

· Utilization of iron ore and coal fines for extracting metal is of vital concern for resource conservation and pollution control. The other option is to convert the iron ore and coal/coke fines into composite pellets/briquettes. By producing iron orecoal/coke composite pellets/briquettes from iron ore and coal/coke fines, utilization of these fines takes place as well as new feed materials are ...

iron ore waste utilistation

Iron Ore Waste Utilistation. Utilization of iron ore tailings as fine aggregate in Jan 15 2014 Natural sand and iron ore tailings were used as aggregates The natural sand was originally excavated from the lower reaches of Yangtze River and had an apparent density of 2 63 gcm 3 The tailings were obtained from the local iron and steel industry and had an apparent density of 2 62 gcm 3 The ...

Iron In Waste From Iron Tailings

iron ore waste utilistation . iron ore tailings which is the waste products of mining industries is used as an alternative to the river sand in the manufacturing of concrete The KIOCL company. Get Price. iron ore waste as coarse aggregate in concrete . iron ore waste as coarse aggregate Effect of Replacing Sand by Iron Ore Tailings on the Compressive sand partially or completely in cement ...

Effect of Iron Ore Tailing on the Properties of Concrete

The successful utilization of iron ore tailing (IOT) as fine aggregate would turn this waste material into valuable resources, reduction in the strain on the supply of natural sand, and economy in concrete production. World production averages one billion metric tons of raw ore annually. The sea borne trade in iron ore, that is, iron ore to be shipped to other countries was 849 metric tons in ...

iron ore waste utilistation

iron ore waste utilistation. Solid Waste Management in a Steel PlantIspatGuru. Sep 29 2014 · GCP wet sludge (in case of wet gas cleaning) from the clarifier is dried and is either blended with the iron ore fines in the raw material yard or briquetted and recycled in sinter making. Refractory waste from the ladle repair shop is sold and the same is used by the refractory manufacturer in the ...

Latest Posts

- سحق مطحنة متنقلة

- استعادة خام الحجم من الحديد المقطوع بعد التكسير

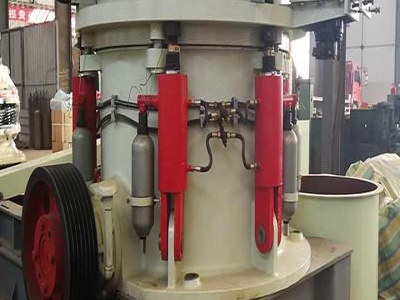

- المراكز الصحية اسطوانة HYD raulic مخروط محطم

- مصنع غسيل الذهب الغريني السعودية

- كيفية تصميم مطحنة الكرة ومبدأها

- مخروط محطم عمودي طحن مصنع الاسمنت

- تستخدم مبيعات مطحنة الكرة في المملكة العربية السعودية

- حجر سحق سعر الجهاز مصر

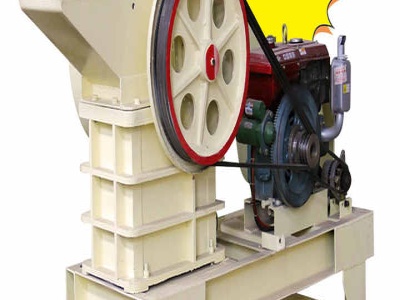

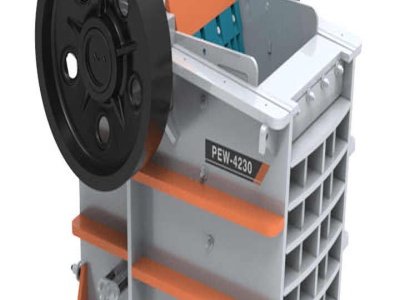

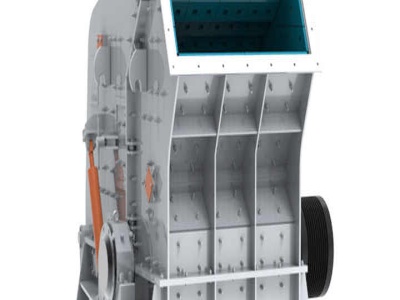

- آلة كسارة الحجر أو كسارات الصخور

- مزود كسارة الحجر الجيري الصغيرة في المملكة العربية السعودية

- مصنعي غسيل الرمال clatec

- معدات معالجة خام السيليكون

- خام مطحنة الكروم متناهية الصغر المورد

- كسارة الرخام البائع لإنتاج

- تستخدم كسارة الحجر للبيع في دلهي

- Iron Ore Supply In Saudi Arabia Saudi Arabia

- Angola Gold Mining In Angola

- Pt Bueno Energy Argentina Coal Mining Dan Trading

- Concrete Quarry Plant Price

- Gold Core Crushing Epuipment In The Republic Of Mongolia

- Nickel Mining Processing

- Roller Malaysia Belts

- Pulverizer Machine In Syria

- Kimia Terbaik Mengolah Batu Emas Dan Cara

- What Is The Dam Ring In Vertical Rollers Mill

- Ball Mill Liner Bolt

- Hematite Ore Processing Machine

- Fuerza Para Girar Un Motor Electrico

- Rock Mozambique Otherthere

- Indonesia Plant Kiln Structure