Materials For Producing Bolivia Roller Mill

Tube Mill, Pipe Mill, Steel Pipe Mill, Steel Pipe Making ...

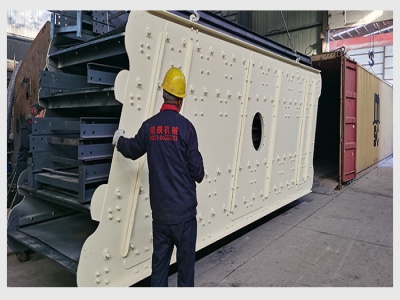

VZH76H Roller Quickly Change Type Automatic Tube Mill Production Line. According to customers' feedback: too much time wasted on changing the roller. New Victor developed roller quickly change system can replace the roll in 20 minutes,saving a .

Vertical roller mill for raw Appliion p rocess materials

mill. (5) Ground materials are dried by the flue gas from the kiln. Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan. Results Table Energy saving effect of the vertical roller mill Ball mill .

Pulp and Paper Manufacturing Processes in Papermaking Industry

On the process of paper manufacturing process, in order to finally turn the pulp into paper, the pulp is fed or pumped into giant, automated papermaking machines. One common type is called the Fourdrinier machine, which was invented in England in 1807. Paper pulp is fed into the Fourdrinier machine on a moving belt of fine mesh screening.

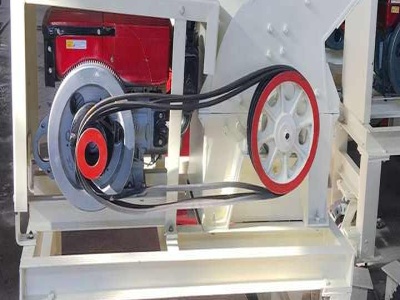

TwoRoll Mill | Rubber Tyre Machinery World

· Let me help you with a quick back of the envelope calculation. If you are using a 270 Liter Tangential Internal Mixer, you are engaging at least two units of 26″x84″ tworoll mills in the downstream section. Each 26″x84″ tworoll mill, requires around 180 kW (minimum) motor power – totaling to 360 kW (=180 x 2) only for the mills.

Roller Mill: Components, Designs, Uses, Advantages and ...

· Roller mill is a form of compression mill that uses a single, double, or triple cylindrical heavy wheel mounted horizontally and rotated about their long axis either in opposing pairs or against flat plates, to crush or grind various materials.

NETZSCHBeads

Grinding beads ideally adapted to NETZSCH agitator bead mills. All important qualities are available in the requested sizes. Optimum combination of machine, grinding tools and appliions. Improved product quality. Process optimization and increase of capacity. .

NETZSCHBeads

Grinding beads ideally adapted to NETZSCH agitator bead mills. All important qualities are available in the requested sizes. Optimum combination of machine, grinding tools and appliions. Improved product quality. Process optimization and increase of capacity. Improved energy efficiency. Excellent grinding bead quality.

China Rolling Mill Roll, Rolling Mill Roll Manufacturers ...

China Rolling Mill Roll manufacturers Select 2021 high quality Rolling Mill Roll products in best price from certified Chinese Machinery, China Roller suppliers, wholesalers and factory on

Design Parameters for a Sugar Cane Extractor

roll mills operated by motor power. Effect Of Compression On Cane Crushers or compressive machine are heavy equipment and are used extensively in the food industry. In jaw crushers, the materials are fed in between two heavy jaws, one fixed and the other reciproing so as to work the materials down in a narrow space, crushing it as it goes.

Selecting the right materials for roll formingmdash;Part 2

· This is the second part of a twopart article. Read Part I. If you examine the mechanical properties of several materials, including carbon steel, alloyed steel, stainless steel, as they relate to roll forming, you'll gain an understanding of the influence of some primary metal processes on roll forming.

Sugar production from cane sugar

roll mill, which is the most common, and the screw expeller. It is important to remember that cane must be crushed within 24 hours of being cut. After this time the sugar begins to 'invert' into different sugars that will not set solid. Roll mills Roll mills, of various types, are a proven technology which are easy to use and maintain

Flexible milling and grinding solutions that last | FL

Our vertical roller mills, horizontal mills, hydraulic roller presses and stirred mills have for many years offered efficient milling and grinding, flexibility, cost savings and easier maintenance. Whatever the appliion, one of our robust milling and grinding solutions will be suitable for grinding all types of feed materials including hard rock ores, raw, cement or slag.

Grinding Media Grinding Balls | Milling Media

Milling balls made of steel and ceramic are our most popular materials. MSE Supplies provides quality, durable, and high performance milling media. We urge our customers to select the best grinding media to fit their needs and production costs.

Cement grinding Vertical roller mills versus ball mills

Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system. However, despite these benefits ...

Feed Mills Engineering, High Quality Feed Milling Machines ...

Feed mill industry solutions. Muyang is the global leader in feed machinery manufacturing and engineering installation, feed machinery standardization and feed industry technological progress promotion. Muyang export products and solutions to more than 80 countries worldwide. Muyang provides feed production industry with comprehensive solution ...

How flour is made

This new type of mill used metal rollers, rather than millstones, to grind wheat. Roller mills were less expensive, more efficient, more uniform, and cleaner than millstones. Modern versions of middlings purifiers and roller mills are still used to make flour today. Raw Materials

12 Tile Manufacturing/Production Process StepbyStep | A ...

The plastic raw materials provide strength and plasticity to the green compact; The nonplastic raw materials provide the liquid phase needed for verifiion and also provides strength to the fired body. feldspar is a nonplastic material. Wet Grinding. The raw materials are taken in a ball mill and them grinded with water for certain hours.

1. Hot rolling and rolling defects: Front and back ...

spring. Normally elastic constant for mills may range from 1 to 4 GNm1. Roll elastic deformation may result in uneven sheet thickness across. Roll material should have high elastic modulus for reducing the roll def ormation. For producing very thin gage sheets like foils, small diameter rolls are used. They are supported with larger rolls.

Yoder

Yoder offers multiple standard tube mills for common product sizes. In addition to the standard machines, Yoder also offers specialized equipment that includes a wide diameter range of metal tubes and pipes; from the 3/16″ () cold stretch reducing mills to the 28″ OD cage mills.

Tube Mill, Pipe Mill, Steel Pipe Mill, Steel Pipe Making ...

VZH76H Roller Quickly Change Type Automatic Tube Mill Production Line. According to customers' feedback: too much time wasted on changing the roller. New Victor developed roller quickly change system can replace the roll in 20 minutes,saving a lot of labor and time. Inquiry

Latest Posts

- المعدات المعدنية وعملية معدات

- سعر عملية تكسير وطحن الحجر الجيري

- الجرانيت المحمول كسارة الحجر مصنع

- كسارة الصين 150 tph الأثر

- الكرة مطحنة مقابل الرأسي مطحنة الحجر الجيري

- نوع الفحم المستخدم في صناعة الاسمنت

- خام النحاس المطحنة لفة مخروط

- خام البوكسيت للبيع

- عمان آلة محطم

- تكلفة معدات مصنع الطوابع

- 200tph نموذجية وحدة كسارة الفحص المتنقلة

- صور كسارة الحجر المتنقلة

- الكسارة المطرقية

- محطم خام الحديد صغيرة

- ذبابة محطة معالجة الرماد في مصر

- Gold Industry Wash Plant

- Spare Part Parker Guatemala Company

- Concrete Mozambique Recycler Rentals

- Mine Ventilation Masurement Honduras

- Stone Stamping Machine For Sale

- Mine Detection Pakistan

- Concrete Jaw Thailand Concrete Jaw Crushers

- Buy Antique Rock Russia

- Mongolia Plant Ilst

- Wet Magnetic Separation Iron Oxide

- Armenia Made Ore Processing Plant

- Old Super Thin Mill In Sri Lanka

- Mining Industry In All Over The World

- Metal Separator Bolivia Coal Samac

- Cs Cone Sudan Parts In Sudan