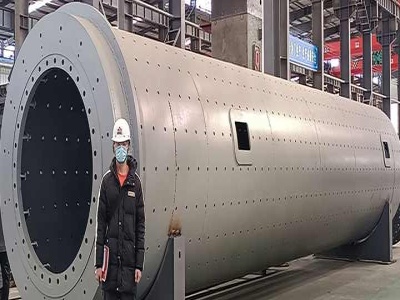

Efficiency Of Ecuador Ball Mill

Energy efficient cement ball mill from FL

For ball mills operating in closed circuit, the circulation load is monitored by weighing the flow of reject material from the separator. These measures ensure you achieve optimum mill performance, giving you the quality, efficiency, safety and reliability that you need.

Ball mill media optimization

("Ball mill classifiion system optimization through functional performance modeling," Nov. 17, McIvor et al., 2017, Mining Engineering) described circuit classifiion system efficiency (CSE), equal to the percentage of coarse (plus circuit P80 target size) material in the ball mill. It can be measured and then increased through

Optimization and Performance of Grinding Circuits: The ...

The ball mill grinding efficiency was poor and could be indied by the fraction < 125 µm of only 59 % or x. P, 80: >400 µm in the mill discharge. This was deemed due to poor hydrocyclone performance which was characterized by higher feed solids content, coarser overflow x. P, 80

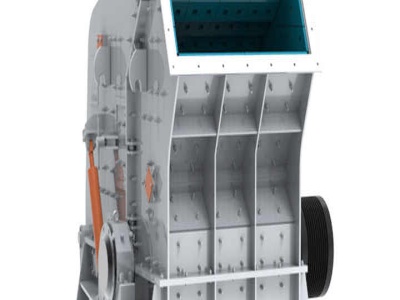

Hammermills versus roller mills | ...

By using a roller mill, or adopting roller grinding principles as part of the feed mechanism on entry to the hammermill, the raw material is partially ground at that point, which then allows the hammers and screens in the grinding chamber of the hammermill to be fully effective, with .

Particle size reduction, screening and size analysis ...

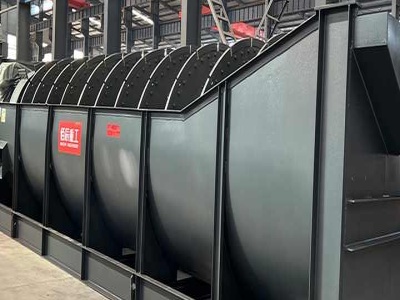

place in ball, pebble or rod mills. The efficiency of wet grinding can be higher than that for dry grinding, but wear of equipment is also higher. Usually, some form of separation follows size reduction. The most common is simple screening, in which the screen openings are selected to pass the desired size range and retain material that is too ...

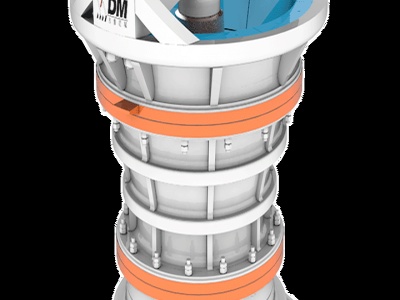

Mill Speed

Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

Ten Ways to Improve the Grinding Efficiency of Your Ball Mill

· There are a lot of problems that most mineral processing plant meet when operating the ball mill, such as low grinding efficiency, low processing capacity, high energy consumption, unstable ...

Efficiency of Ball Mills vs. Roller Mills

· Efficiency of ball mills vs. roller mills I would like to know if anybody knows the power consuption in KW per ton of a ball mill milling cement clinker at a feed of 1" minus in order to produce Portland Cement. I would also like to get the same info for a roller mill. 7th April 2008, 9:12 #2. ...

THE OPTIMAL BALL DIAMETER IN A MILL

The ball impact energy on grain is proportional to the ball diameter to the third power: 3 E K 1 d b. (3) The coefficient of proportionality K 1 directly depends on the mill diameter, ball mill loading, milling rate and the type of grinding (wet/dry). None of the characteristics of the material being ground have any influence on K 1.

Ten Ways to Improve the Grinding Efficiency of Your Ball Mill

· There are a lot of problems that most mineral processing plant meet when operating the ball mill, such as low grinding efficiency, low .

How to improve the efficiency of ball mill_Dongding Machine

· Increasing the grinding area of the ball mill can improve the efficiency and output of per unit time. The grooveshaped ring liner is used to increase the contact area of the material, enhance the grinding effect, improve the production capacity.

The Most Efficient Way of Improving Grinding Efficiency of ...

There are many factors influencing the grinding efficiency of ball making machine. As for one ball mill grinder, when processing one mineral, the influencing factors of grinding efficiency include property of grinding media, matching of grinding media, filling ratio of grinding media, ratio of grinding balls to materials, grinding density and feeding granularity.

MODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLING

Ball mill = coarse particles (in the plant ball mill) grinding efficiency Ore grindability (in the lab ball mill) The units of "ball mill grinding efficiency" will be covered in detail in the first part of the module. Alternatively, we can say that: Specific grinding rate = Ball mill x Ore grindability

Modelling: Transfer size limits

For example, the SAG mill may have 10 MW of power draw available and the two ball mills each of MW of power draw available for a total of ratio of 10:15 (1:). The software uses the particular power model (Bond/Barratt, Morrell Mi, etc.) to determine what is the transfer size where the ratio of E SAG to E ball matches the ratio of mill power (1: in this example).

ecuadorian ball mills manufacturers」

· ecuadorian ball mills manufacturers_ecuadorian ball mills manufacturersMineral Processing EPCAntimony, Antimony Suppliers and Manufacturers at ecuadorian ball mills manufacturers. High Quality 1# Antimony Ingot % Manufacture

C O N S U L T I N G L T D TECHNICAL MEMORANDUM

crushing and singlestage ball milling circuit. Barratt, 1989, writes that a copper porphyry ore in a powerefficient circuit of SAG milling followed by ball milling should be 10% less efficient that the "maximum efficiency" grinding circuit (crushing, singlestage ball mill). Thus, the Etotal of a SAG and ball mill circuit is: Etotal= ...

7 Differences Between Ball Mill and Rod Mill

· Ball mill and rod mill are the common grinding equipment widely used in the mineral processing plant. They are similar in shape and grinding principle, but also different in structure, performance and appliion. Here are seven differences between ball mill and rod mill to tell you how to choose the ball mill and rod mill.

(PDF) INVESTIGATION OF EFFECTS OF GRINDING MEDIA .

Ball mills are equipments which has balls as grinding media and used for last step of grinding process. There are many factors which effect grinding performance of ball mills like; liner design ...

Bond Grinding Circuit Efficiency

Mill Ball Mill Closed circuit crushing to 16 mm Open circuit 8' dia. rod mill to 1 mm Closed circuit 8' dia. ball mill to P80 um The ore Test Work Index = Circuit Operating Work Index 9 The Standard Bond Circuit Coarse Ore Bins Fine Ore Bins Screen Crushing Screen Classifiion Rod Mill Ball Mill THIS IS THE REFERENCE BASIS FOR ALL WORK ...

Optimization of mill performance by using

charge motion. It is well known that ball milling efficiency varies during the lifetime of the shell liner. For instance, the mill performance could become worse or better by putting in a new shell liner. Data from pilot plant test work illustrates the influence of the shell lifting effect on the grind for a primary grinding duty.

Latest Posts

- وحدة كسارة صغيرة

- عجلة سحق معدات

- استخدام الحجر آلة كسارة للبيع

- كسارة الحجارة 2 كسارة الفك الأولية

- كسارات البنتونيت

- عملية مطحنة البوكسيت تدفق المخططات

- خام مزود مخروط محطم في السعودية

- en كسارة صخور محمولة للبيع في مصر

- برنامج صيانة محطة التكسير

- كسارة فكية prin le

- الموردين آلة محطم في السودان

- تصنيع معدات التكسير

- 20 كسارات الأسفلت الصغيرة tph

- كسارات المطرقة عملية العمل

- مصنع المحمول الصغيرة لمعالجة المعادن

- Secondary Jaw Pakistan 8x30

- Charcoal Coal Making Process

- Oman Oman Plants Quarries

- Working Mechanism Of The Screen In Jamaica Ppt

- Small Scale Sinter Sri Lanka

- Cnc Machines Repair In Oman

- Mining Uzbekistan Picture

- Raymond Roller Mill 2013

- Mobile Coal Cone Ecuador Suppliers Ecuador

- Concrete Breaker Jaw Crushing Ores

- Feldspar Crushing Company In Russia

- Concrete Portugal For Sale Jaw Portugal

- Jaw United Arab Emirates Crushing Efficiency

- Xtruder For Sale

- Frac Sand For Sale In Honduras