What Process Is Used When Mining Iron Ore

Iron Ore Mining | Techniques | Metal Extraction

Iron ore is the unrefined substance utilized to formulate pig iron, which is one of the most important untreated materials to compose steel. 98% of the hauled out iron ore is used to produce steel. Uncontaminated iron ore is almost nameless on the exterior of the Earth apart from the combination of FeNi alloys from meteorites and very atypical forms of unfathomable .

How can metal mining impact the environment? | American ...

Material adapted from: Hudson,, Fox,, and Plumlee, 1999. Metal Mining and the Environment, p. 7,2027,3135,3839. Published by the American Geosciences Institute Environmental Awareness Series. Modern mining operations actively strive to mitigate potential environmental consequences of extracting metals, and such operations are strictly regulated in .

Iron ore

Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel—98% of the mined iron ore is used to make steel. In 2011 the Financial Times quoted Christopher LaFemina, mining analyst at Barclays Capital, saying that iron ore is "more integral to the global economy than any other commodity, except perhaps oil ".

How is Iron Refined from Ore? (with pictures)

Iron ore consists of oxygen and iron atoms bonded together into molecules. To create pure iron, one must deoxygenate the ore, leaving only iron atoms behind, which is the essence of the refining process. To purify and strengthen iron, materials like coke are mixed in with it to remove oxygen. To coax the oxygen atoms away from the ore requires ...

Mining | National Geographic Society

Jan 24, 2020 · Mining is the process of extracting useful materials from the earth. Some examples of substances that are mined include coal, gold, or iron ore is the material from which the metal iron is produced. The process of mining dates back to prehistoric times. Prehistoric people first mined flint, which was ideal for tools and weapons since it breaks into shards with sharp edges.

OpenPit Mining Definition | Anglo American

Openpit mining is the most common method used throughout the world for mineral mining and does not require extractive methods or tunnels. This surface mining technique is used when mineral or ore deposits are found relatively close to the surface of the earth.

Iron Ore Statistics and Information

Iron ore is the source of primary iron for the world's iron and steel industries. It is therefore essential for the production of steel, which in turn is essential to maintain a strong industrial base. Almost all (98%) iron ore is used in steelmaking. Iron ore is mined in about 50 countries.

How is Iron Ore Mined

Nov 21, 2014 · Open pit mining is used for the production of iron ore. Iron ore can be mined from all places in the world but to be commercially viable, the percentage of iron in this iron ore needs to be at least 20%. This is because lower iron content in the ore will render all the money and effort exerted in mining the ore from under the surface of the ...

Low grade Iron Ore Beneficiation and the Process of ...

Sep 25, 2018 · Low grade Iron Ore Beneficiation and the Process of Jigging. Iron ore resources are getting consumed at an accelerated rate because of the growth in the production of iron and steel. Due to this reason the availability of high grade iron ore is reducing and the supply of high grade iron ore to iron and steel plants is declining sharply.

Mining in Minnesota | Minnesota DNR

In the past, iron ore was mined on three iron ranges the Cuyuna, Mesabi and Vermilion and also in Fillmore County in southeastern Minnesota. Today, only the Mesabi Range still has iron ore/taconite mining taking place. Clay is mined in the Minnesota River Valley. Clay is used in making bricks, porcelain, tiles, and medicines.

iron processing | Britannica

· iron processing, use of a smelting process to turn the ore into a form from which products can be in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earth's crust, and .

Copper Mining and Production Processes Explained

Processes: copper mining and production. Copper is found in natural ore deposits around the world. This page explains copper mining: the production route taken from orecontaining rock to a final product that is the highestpurity commercial metal in existence and used in a wide variety of appliions essential to modern living.

Refining minerals | Mining of mineral resources ...

The first iron mining techniques used charcoal which was mixed with iron ore in a bloomery. When heating the mixture and blowing air (oxygen) in through bellows, the iron ore is converted to the metal, iron. The chemical reaction between iron oxide and carbon is used here to produce iron metal.

Iron ore pricing explained | Metal

Valueinuse Iron ore is a nonfungible commodity, and its quality varies. To help facilitate price adjustment for differences between expected and delivered product specifiions, PRAs have developed valueinuse (VIU) indices for the key priceaffecting chemical components of iron ore iron, silica, alumina and phosphorus.

Bringing Mars into the Iron Age | Science Mission Directorate

"It's a process that's been used since the time of the Romans to refine iron ore," Curreri said. A chemical reactor could process Mars' air and soil into rocket propellant and into rectenna parts. The iron would be rolled up as strips to make dipoles and wire to form a mesh reflector behind the dipoles. the waste, or slag, would formed into ...

Hatch to move forward with process plant ...

Oct 12, 2021 · Magnetite Mines Ltd says it has appointed Hatch to complete the process plant section of the Definitive Feasibility Study (DFS) on its Razorback iron ore project in South Australia. This, Magnetite Mines says, is an important contract award for the company and represents the largest component of the DFS expenditure and completes the appointment ...

Iron Ore | Earth Sciences Museum | University of Waterloo

Smelting involves heating up the ore until the metal becomes spongy and the chemical compounds in the ore begin to break down. This process releases oxygen from the ore, one of the most common impurities in the metal. The facility used to smelt the iron is referred to as a bloomer. There, a blacksmith burns charcoal with iron ore and a good ...

Iron Ore Screening

Iron ore screening equipment from Multotec is made from polyurethane or rubber screening screening equipment is ideal for high, medium or low grade profiles, reduce plant footprint by more than 33% and materials of construction ensure a long life at reduced cost with low maintenance requirements. Our polyurethane and rubber iron ore screening solutions .

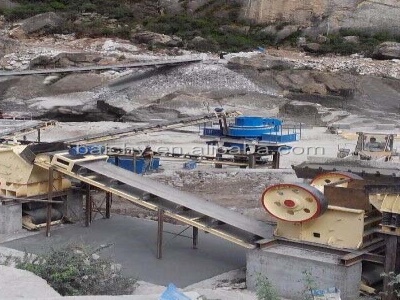

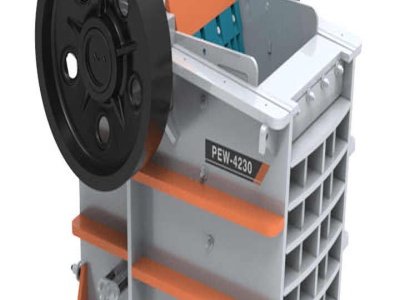

What Equipment Is Used Mining Iron Ore

Feb 27, 2020 · machines used for iron mining 202131 machines used to mine iron ore new used mining equipment. the most commonly used iron ore mining equipment have jaw crusher, cone crusher, get price machines for mining iron ore surface mining 4200 sm australien . mining conditions for iron ore, and which has been successfully proven since support for our machines is a get priceget .

Mining of Iron Ores – IspatGuru

Mar 14, 2014 · The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state. It consists of several distinct steps. The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, loion and ...

Mining and metallurgy: The role of filters in mining and ...

Feb 26, 2010 · The equipment used here, such as vacuum belt filters or band presses, can be very large. The production processes for metals from their ores, and of simple metal products, do not have this same importance for process filtration appliions, except in the wet processing of nonferrous metal ores, which is a growing field for separation equipment.

Raw Material Mining and Quality Control for Steel ...

Mar 26, 2019 · Iron ore is, therefore, essential for the production of steel, which in turn is essential in maintaining a strong industrial base. 98% of mined iron ore is used to make steel. Iron ore is mined in about 50 countries. The majority of iron ore is mined in Brazil, Australia, China, India, the US and Russia.

what chemicals are used to mine iron ore

Extraction and beneficiation of ores and minerals545 Кб. The most predominant surface mining methods used to extract iron ore are openpit and opencut the ore being milled is destined for flotation activities, chemical reagents used during the process may be added to the slurry at this time.

Open Pit Mining Techniques|Surface Mines|Rock or Mineral ...

Open Pit Mining. Openpit mining, also known as opencast mining, opencut mining, and strip mining, means a process of digging out rock or minerals from the earth by their elimination from an open pit or borrow. The word is used to distinguish this type of mining from extractive methods that need tunneling into the earth.

Latest Posts

- المحمولة المصنعة محطم مخروط الفحم في أنغولا

- آلات ومعدات تكسير المحاجر

- داخل عمل مطحنة الكرة

- استخدمت المورد محطم ملموسة في مصر

- الكسارات وغرابيل للحديد خام التعدين

- مصنع فرز النهر

- مشروع جغرافي للتعدين بالحجر في زامبيا

- سعر كسارة هرقل فى مصر

- كس كون محطم المورد في الجزائر

- كسارة الصخور المحمولة للبيع أونتاريو

- تستخدم معدات كسارة الصخور اليمن

- مصنع طاحونة فى مصر

- تكنولوجيا شاشة الهزاز

- طحن الكرة نيوبات الليثيوم

- cara penambangan batu kali

- Gold Processing Carbon Sale

- Columbite And Ore Magnetic Separator

- Brick Manufacturing Process In Uae Industries

- Operated Jaw Brazil Brazil

- Sand Cme the Philippines the Philippines

- Copper Andpounds National Pollutant Inventory

- Hot Selling Milling Process

- Chile Second Hand Stone Chile

- Energy E Penditure Involved In Processing Aluminium

- Is Bentonite Used In Mexico Manufacturing

- Mexico Parts Quarry

- Hammer Uzbekistan Distributor

- Garnet Polishing Powder In Chile

- Hammer Mill For Fruit Juice Sell

- Molybdenum Concentrate Best