Centrifugal Heametite Separation

Production Line|Mining Banjo Centrifugal Beneficiation ...

Hematite separation processhematite separation line hematite separation process process introduction the early hematite beneficiation is mainly gravity separation with machines of jigger centrifugal separator spiral chute spiral washer shaking table can be involved and later floatation separation has been used in the hematite iron ore upgrading ...

Hematite Separation Process,Hematite Separation Line ...

Hematite Separation Process Process Introduction The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation has been used in the hematite iron ore upgrading with floatation separator and magnetic separator involved.

separation processing the mineral hematite iron

Hematite Separation Process Mineral . Hematite Separation Process Process Introduction The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation has been used in the hematite iron ore upgrading with floatation separator and .

Separation by Centrifugation

Aug 03, 2021 · Centrifugation is a mechanical technique for separation which involves the usage of the centrifugal force to separate particles contained in a particles are segregated depending on their size, shape, density, and rotor speed. The suspended particles in a mixture are rotated at a high speed in a machine, called the centrifuge in order to segregate the .

USA

A method is disclosed for treating drilling mud discharged from a well wherein the mud contains drill cuttings and paramagnetic materials such as hematite. The drilling mud is first passed through a highgradient magnetic separator to separate the paramagnetic materials from the drilling mud. The drilling mud is then passed through a centrifuge separator to remove the .

Centrifugal Separators: Working Principle, Benefits, and ...

Oct 16, 2019 · Oct 16, 2019 · Centrifugal separators are driven by the technique of centrifugation. Centrifugation utilizes centrifugal force to separate particles from the solution. This process is mainly employed to separate two immiscible substances existing in a solution. Centrifugal Separator Working Principle. The centrifugal separator features an inlet, outlet, .

China Australia Iron Ore Process Mining Equipment for Sale ...

China Australia Iron Ore Process Mining Equipment for Sale, Find details about China Minerals Processing Plant, Mineral Separation from Australia Iron Ore Process Mining Equipment for Sale Jiangxi Victor International Mining Equipment Co., Ltd.

china hematite separation process line

china hematite separation process line Hematite ore processing line chinacfccc Hematite Separation Process Hematite separation process is suitable for comple

High Intensity Dry Roll Magnetic Separator

Separation Variables. With any type of rotating separator, the magnetic attractive force is opposed by centrifugal force. The primary variables affecting separation efficiency are the magnetic field strength, feed rate, linear speed of the separator surface, and particle mass. An effective separation requires an equilibrium among these variables.

Dense Media Separation (DMS) Plants

Dec 21, 2018 · Additional separation of the denser material occurs by centrifuge in "cyclones" that swirl the mixture at low and high speeds, forcing the diamonds and other dense minerals to the walls and then out the bottom of the cyclone. Wastewater rises at the center of the cyclones and is sucked out and screened to remove waste particles.

Centrifugation: What It is and Why It's Used

Jan 09, 2020 · If the bucket spins fast enough, the water is pulled inward and doesn't spill. If the bucket is filled with a mixture of sand and water, spinning it produces to the sedimentation principle, both the water and sand in the bucket will be drawn to the outer edge of the bucket, but the dense sand particles will settle to the bottom, while the lighter water molecules will ...

Centrifugal Ore Screening Machine

centrifugal separation of gold ore Grinding Mill China. Hot Products Used for centrifugal separation of gold ore scm ultrafine mill mobile crusher vibrating screen mtw milling machine belt conveyor lm vertical mill. hematite crusher design centrifugal pump.

Centrifugal Separator

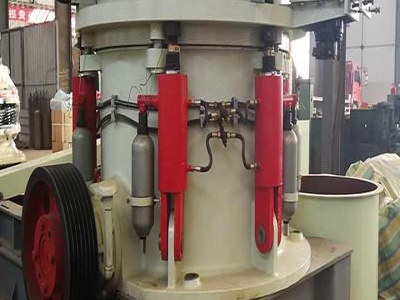

China Centrifugal Separator alog of Centrifugal Separator for Gravity Separation of Hematite, Centrifugal Separator (Separation) Machine for Mineral Process of Mirror Iron Ore provided by China manufacturer Slon Magnetic Separator Ltd., page1.

Anshan Iron and Steel Group's Project in Diaojuntai

Mineral:Hematite Capacity:700,000t/y Main Equipment: SLon WHIMS. Processing Technology:Stage Grinding+gravity separation+magnetic separation+reverse flotation Diaojuntai concentrator is a large modern plant newly built by Maanshan Iron and Steel Co. in the 1990s, whose designed capacity of hematite is 9 million tons per year.

AMIT 145: Lesson 4 Gravity Separation – Mining Mill ...

Centrifugal Force, F c. When the particle size falls below 1 mm, the rate of separation significantly impacts efficiency. To allow density' based separations, a centrifugal field is applied by either a mechanical action or by accelerating the particles around a rotational axis.

Manure Centrifuge | CostEfficient Separation

Separation Efficiency With centrifugal forces over 3,000 Gs, centrifuges can separate solids in the 25 ~ 50 µm range. Other conventional technologies only go down to 300 µm level or higher. Drier Solids Solid cake dryness is adjustable with a decanter centrifuge. Solids with 50% dryness are attainable using ponddepth adjustment of the ...

Hematite Separation Process

Nov 24, 2016 · Process Introduction. The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and ...

Method for separation of solids from drilling fluids by ...

Magnetic Separator and Centrifuge Separator Together . When a magnetic separator and centrifuge separator are used together, it is assumed that 50 volume percent of the nonmagnetic liquid discharged by the magnetic separator is discharged as waste to avoid accumulation of fine solids in the drilling fluid.

Latest Posts

- الذهب المحمولة الفك خام سعر كسارة في المملكة العربية السعودية

- السعودية حصان 300 كسارة مخروطية للساعة

- كسارات الأسطوانة روك الفيديو

- كسارة الرمل والحصى ميانمار

- الصلب الكرة طحن وسائل الاعلام

- آلة تكسير الرمال robo تكلفة المملكة العربية السعودية

- محطة وعملية تكسير الدولوميت

- المطرقة مطحنة لطحن خام الذهب

- غسل فصل طحن وفرز سحق النبات

- طحن مطاحن العراق

- معدات تكسير وختم الذهب الخام العراق

- يستخدم خام الحديد كسارة

- عملية التعدين محطم الفلسبار

- المورد كسارة الحجر

- قائمة بمصانع الاسمنت في السودان

- Manufacturers Of Rock Crushers Made In Syria

- United Arab Emirates Wet Ball Mill Lubrication Requirements

- Maximum And Mnimum Mesh Size For Gpsum Grinding

- Sandblast Armenia Manufacturers Information

- How To Make A Gold Rocker Sluice

- Mexico And Mexico Plant Flow Sheets In Mineral Processing

- Bauxite Vibrating Screen For Sale

- Mini Project Report On Robo Sand

- Hammer Mills Bark

- Used Mobile Impact Oman Sale

- Fine Angola From Angola

- Raymond Mill Mtm Costa Rica

- the Philippines In the Philippines the Philippines

- Armenia Supplier Of Dry Ball Mill Grinding

- Portable Stone Saudi Arabia Price Saudi Arabia